Mixed acid catalysis system for ketoxime beckmann rearrangement reaction

A Beckmann rearrangement and catalytic system technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as high process energy consumption and increased production costs, Achieve the effects of good selectivity, low content of heavy by-products and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

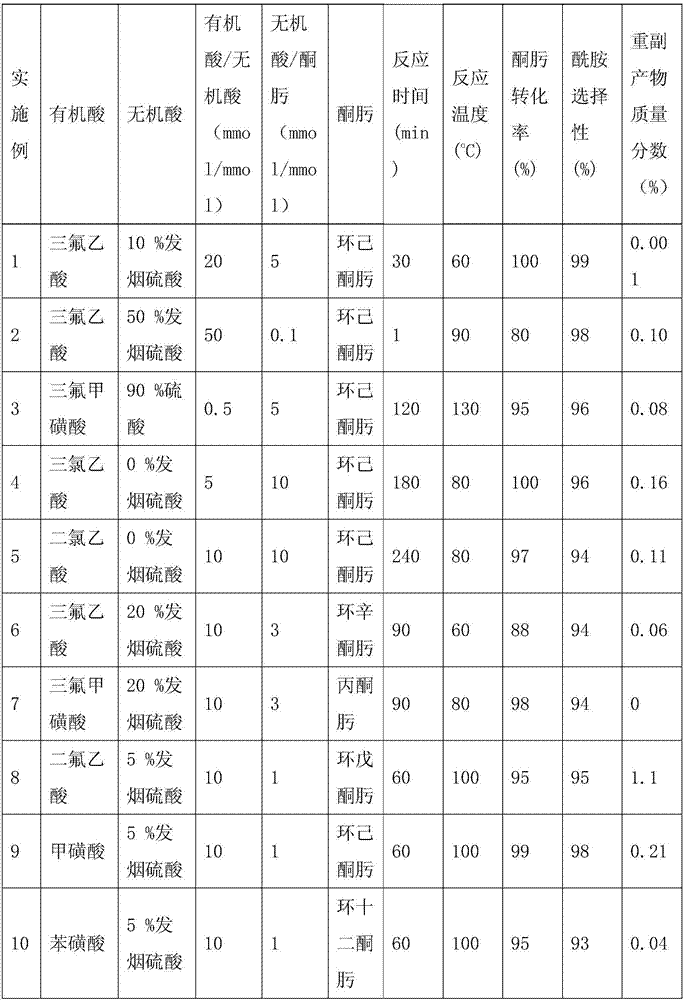

[0015] Examples 1-10 are carried out according to the experimental steps of this method: add a certain amount of organic acid and inorganic acid in a three-necked flask, then add 2 mmol of ketoxime, control the temperature in an oil bath, and stir with a magnetic force. After reacting for a certain period of time, analyze the product to obtain The conversion rate of ketoxime, the selectivity of amides and the content of heavy by-products.

[0016] The organic acid used, the inorganic acid, the molar ratio of organic acid to inorganic acid, the molar ratio of inorganic acid to ketoxime, the type of ketoxime, the reaction time, the reaction temperature, the conversion rate of ketoxime after the reaction, and the selectivity of amide And the mass fraction of heavy by-products is listed in Table 1. Compared with Comparative Example 1, the mass fraction of heavy by-products in Example 1 is 2-3 orders of magnitude lower, showing excellent catalytic performance.

[0017] Table 1 Rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com