Design method of angle of oil hole in process of medium-frequency quenching of crankshaft

A design method and oil hole technology, applied in drilling/drilling equipment, workshop equipment, boring/drilling, etc., can solve the problems of scrapped crankshaft, oil hole cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

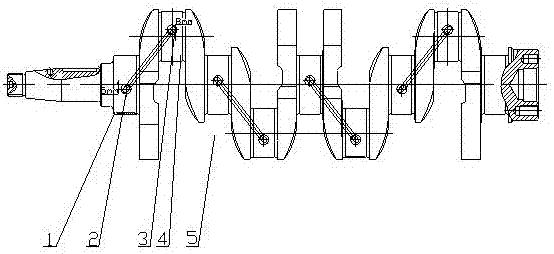

[0018] For this reason, we change the processing position of the oil hole, that is, change the angle of the oil hole to make the hole wall thicker, and no cracking at the hole will occur during intermediate frequency quenching. The specific method is as follows:

[0019] 1) Put the crankshaft on the V-shaped iron on the marble workbench, mark the crankshaft with a height ruler with a knife edge, the position of the oil inlet hole of the connecting rod is 8mm on the center line of the connecting rod journal, and the oil outlet hole of the main shaft The position is 5mm below the centerline of the main shaft, and the position of the oil inlet and outlet holes is at the center of the journal opening, and try not to move along the axial direction;

[0020] 2) Place the marked crankshaft smoothly in the fixture of the oil hole processing machine tool, position and clamp it;

[0021] 3) Slowly and manually approach the drill bit to the crankshaft to see if the marked part of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com