A magnetically controlled k-tig welding torch based on permanent magnet array

A permanent magnet and welding torch technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large space occupation, unfavorable installation and disassembly, and complicated electromagnet devices, so as to save welding manufacturing costs and increase penetration ability , The effect of the compact structure of the welding torch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

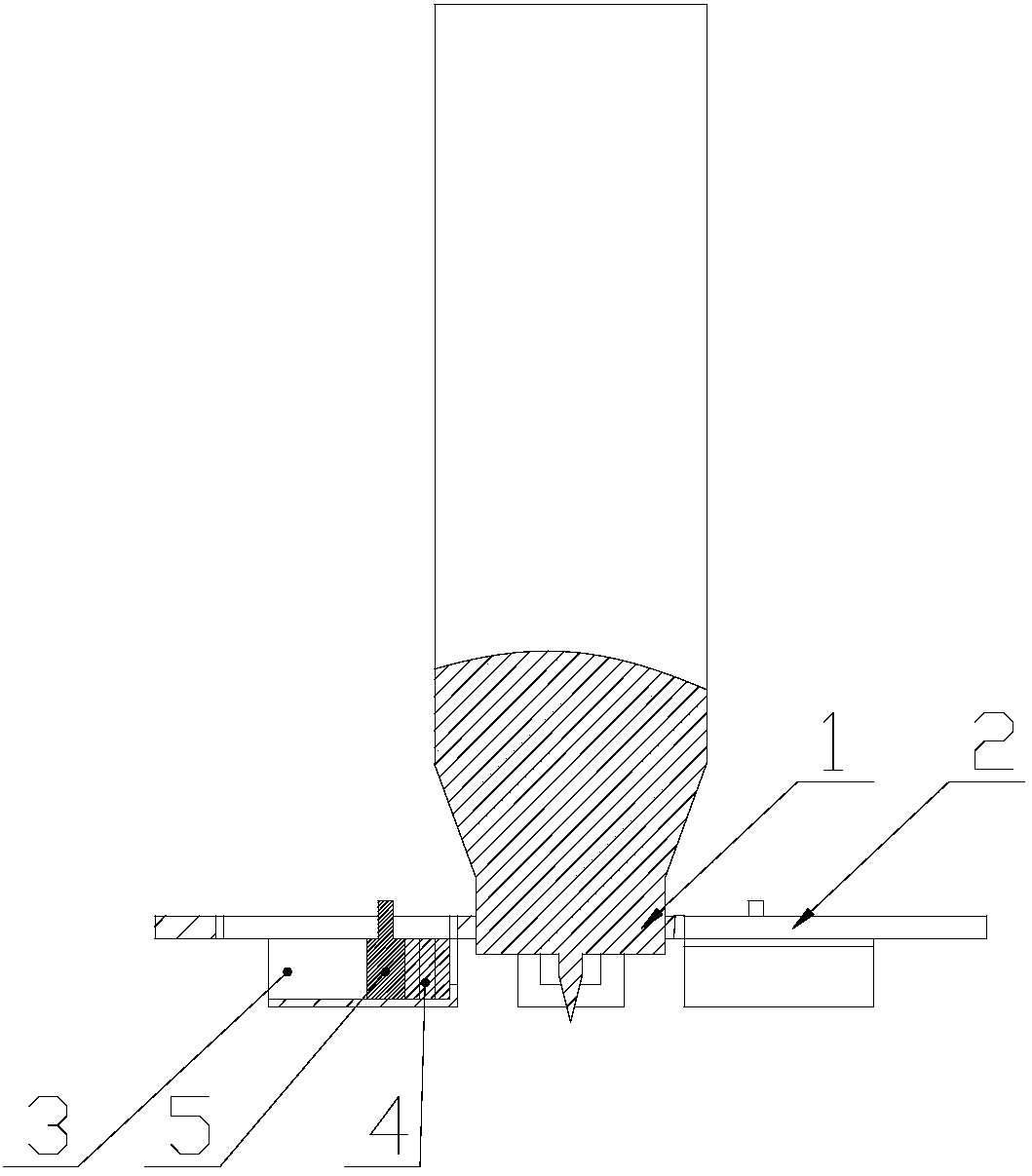

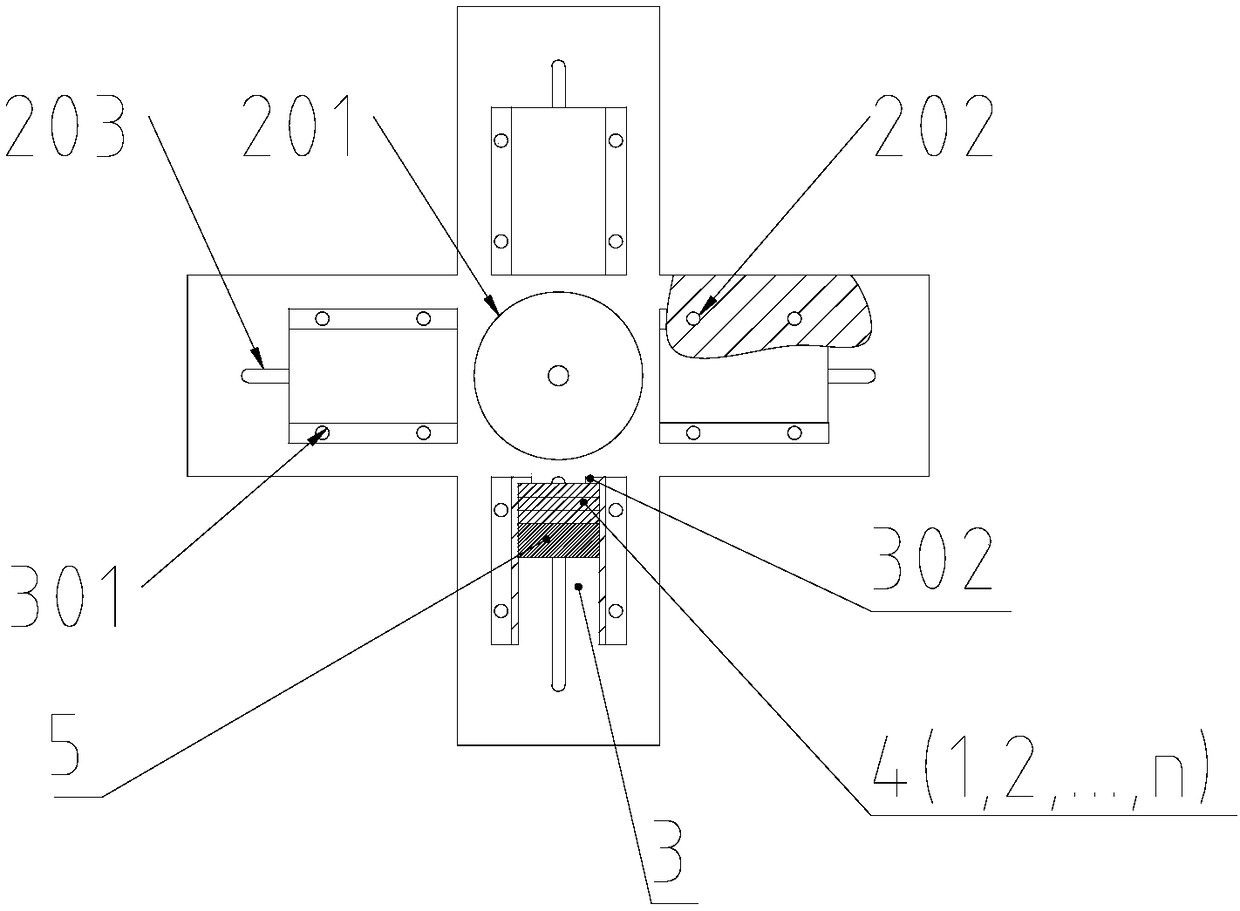

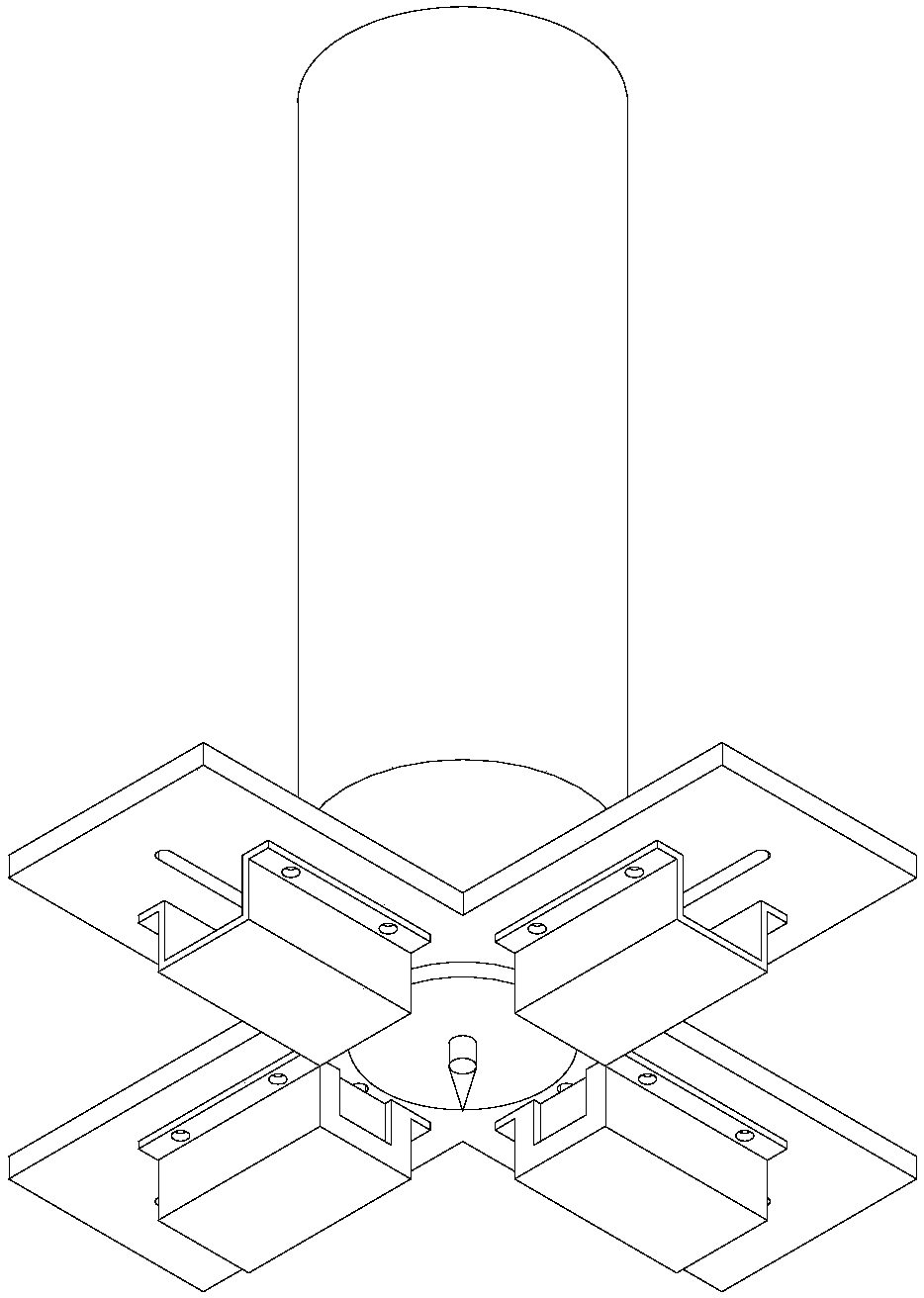

[0028] Such as figure 1 with figure 2As shown, the present embodiment provides a magnetically controlled K-TIG welding torch based on a permanent magnet array. A magnetically controlled device is installed on the lower edge of the copper sleeve of the welding torch head 1. The magnetically controlled device includes a cross fixing plate 2, a magnet fixed Slot 3, permanent magnet 4 and magnet fixing block 5.

[0029] The cross fixing plate 2 is a cross-shaped plate structure with four supporting plates, and its center position is provided with a circular welding torch fixing hole 201 according to the size of the welding torch head 1. The proper position of the torch head 1, and directly or through the gasket material is fixed on the lower edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com