A method, equipment and product for arc additive manufacturing of high-strength aluminum alloy components

An aluminum alloy component and additive manufacturing technology, which is applied in arc welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult forming, easy cracking, and many pores, and achieves improvement of melting behavior, suppression of cracks, The effect of suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

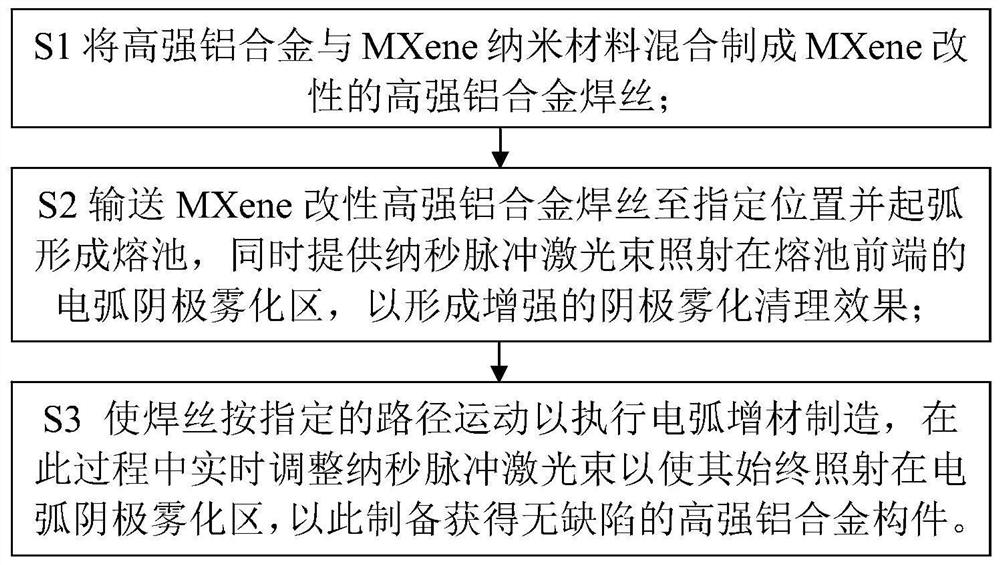

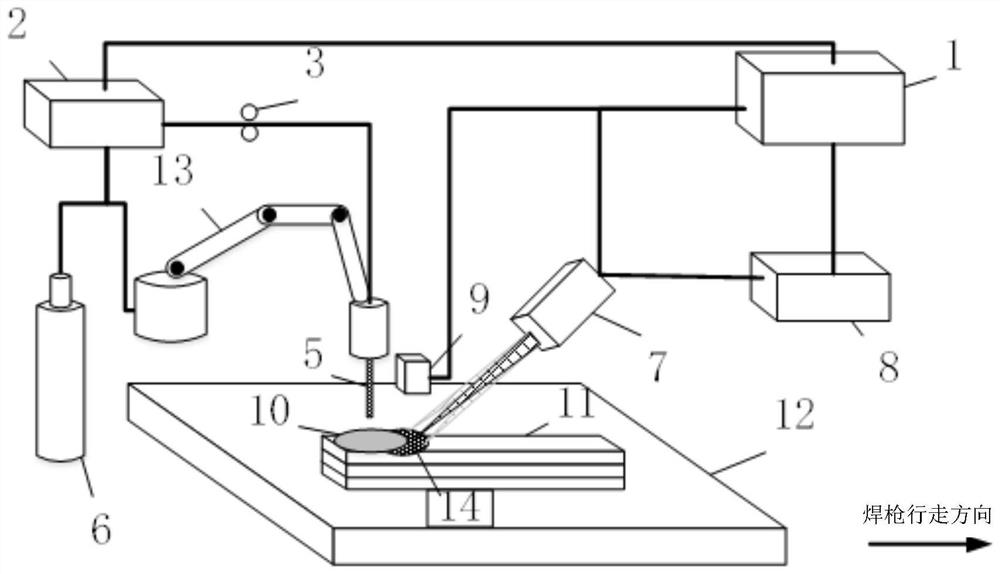

[0058] This embodiment takes 7075 aluminum alloy components as an example to describe the manufacturing method of the present invention in detail, where MXene uses Ti 3 C 2 , including the following steps:

[0059] S1 combines 7075 aluminum alloy with Ti 3 C 2 Powder mixed to make 1.2mm diameter Ti 3 C 2 - MXene modified high-strength aluminum alloy welding wire, wherein the mass ratio of high-strength aluminum alloy powder to MXene nanomaterials is 98:2;

[0060] S2 transports the MXene-modified high-strength aluminum alloy welding wire and starts the arc to form a molten pool. At the same time, it provides nanosecond pulse laser to irradiate the arc cathode atomization area at the front of the molten pool. The nanosecond pulse laser power is 100W, and the laser pulse width The scanning speed is 100ns, the scanning speed is 2m / s, and the beam spot diameter is 0.1mm;

[0061] S3 makes the MXene-modified high-strength aluminum alloy welding wire move according to the spec...

Embodiment 2

[0063] This embodiment takes 7050 aluminum alloy components as an example to describe the manufacturing method of the present invention in detail, wherein MXene uses Ti 3 C 2 , including the following steps:

[0064] S1 combines 7050 aluminum alloy with Ti 3 C 2 Material mixed to make 1.2mm diameter Ti 3 C 2 - MXene modified high-strength aluminum alloy welding wire, wherein the mass ratio of high-strength aluminum alloy powder to MXene nanomaterial is 99:1;

[0065] S2 transports the MXene-modified high-strength aluminum alloy welding wire and starts the arc to form a molten pool. At the same time, it provides nanosecond pulse laser to irradiate the arc cathode atomization area at the front of the molten pool. The nanosecond pulse laser power is 200W, and the laser pulse width The scanning speed is 200ns, the scanning speed is 4m / s, and the beam spot diameter is 0.2mm;

[0066] S3 makes the MXene-modified high-strength aluminum alloy welding wire move according to the s...

Embodiment 3

[0068] This embodiment takes 2319 aluminum alloy components as an example to describe the manufacturing method of the present invention in detail, where MXene uses Ti 2 C, specifically including the following steps:

[0069] S1 combines 2319 aluminum alloy with Ti 2 C powder mixed to make 1.5mm diameter Ti 2 C-MXene modified high-strength aluminum alloy welding wire, wherein the mass ratio of high-strength aluminum alloy powder to MXene nanomaterials is 98.5:1.5;

[0070] S2 transports the MXene-modified high-strength aluminum alloy welding wire and starts the arc to form a molten pool. At the same time, it provides nanosecond pulse laser to irradiate the arc cathode atomization area at the front of the molten pool. The nanosecond pulse laser power is 50W and the laser pulse width The scanning speed is 0.1ns, the scanning speed is 10m / s, and the beam spot diameter is 0.15mm;

[0071] S3 makes the MXene-modified high-strength aluminum alloy welding wire move according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com