Feeding device for magnetic shoe chamfering and grinding and implementation method thereof

A realization method and technology of magnetic tiles, which are applied to the parts of grinding machine tools, grinding feed movement, grinding/polishing equipment, etc., can solve the problems of unsuitable for manual loading, low feeding efficiency, and time-consuming, etc. , to achieve the effect of high promotion value, simple feeding and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

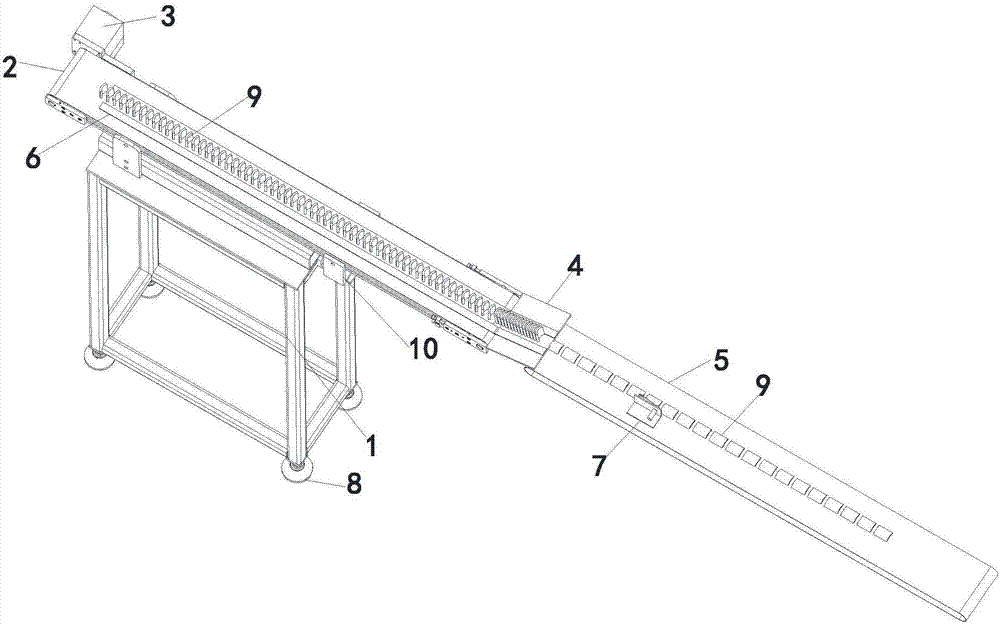

[0032] Such as Figure 1~2 As shown, a feeding device for chamfering and grinding of magnetic tiles includes a frame. A feeding conveyor belt is arranged above the frame. The feeding conveyor belt is driven by the feeding conveyor belt motor. The outlet end of the feeding conveyor belt It is equipped with an uphill board, which is inclinedly arranged, and a discharge conveyor belt is arranged under the uphill board.

[0033] In this embodiment, there are adjustable baffles on both sides of the feeding conveyor belt, and the adjustable baffles are adjusted by the adjusting screws below; the feeding conveyor belt motor is a speed-adjusting motor; the upward slope is 15~75 with the horizontal plane. °Angle.

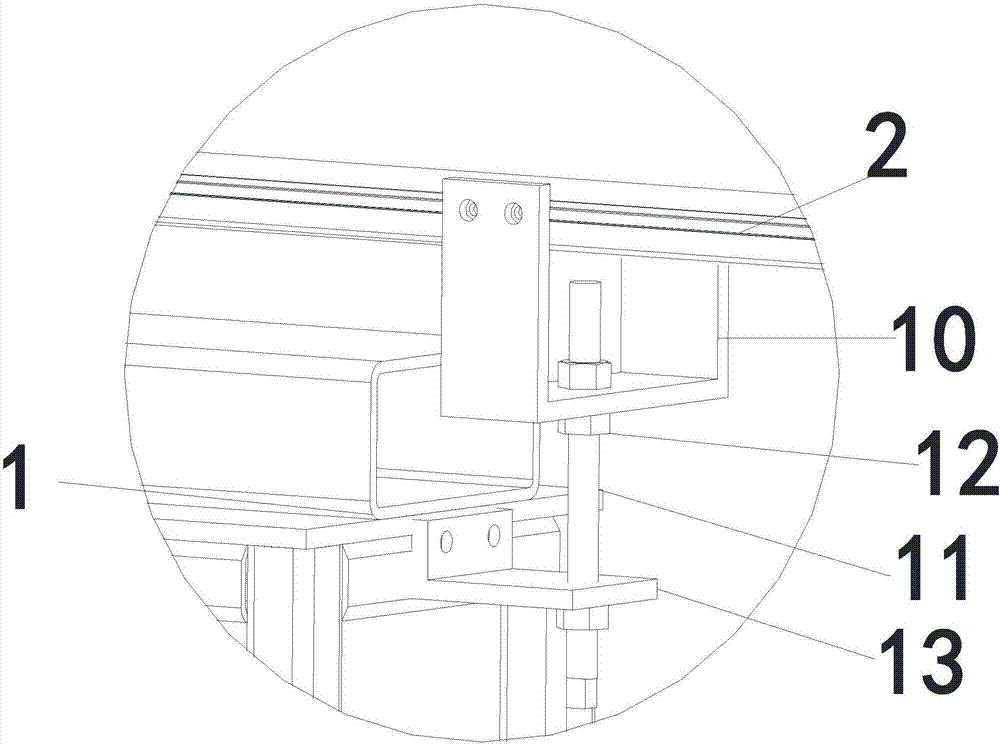

[0034] Such as figure 2 As shown, the lower side of the outlet end of the feed conveyor belt in this embodiment is connected to an adjusting screw through a bracket, an adjusting nut is provided on the adjusting screw, and the lower end of the adjusting screw is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com