Disassembly method of hydraulic cylinder piston head

A piston head and hydraulic cylinder technology, applied in the field of hydraulic cylinder production, can solve problems such as personnel injury, hidden dangers of parts and maintenance personnel, deformation of positioning pin holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

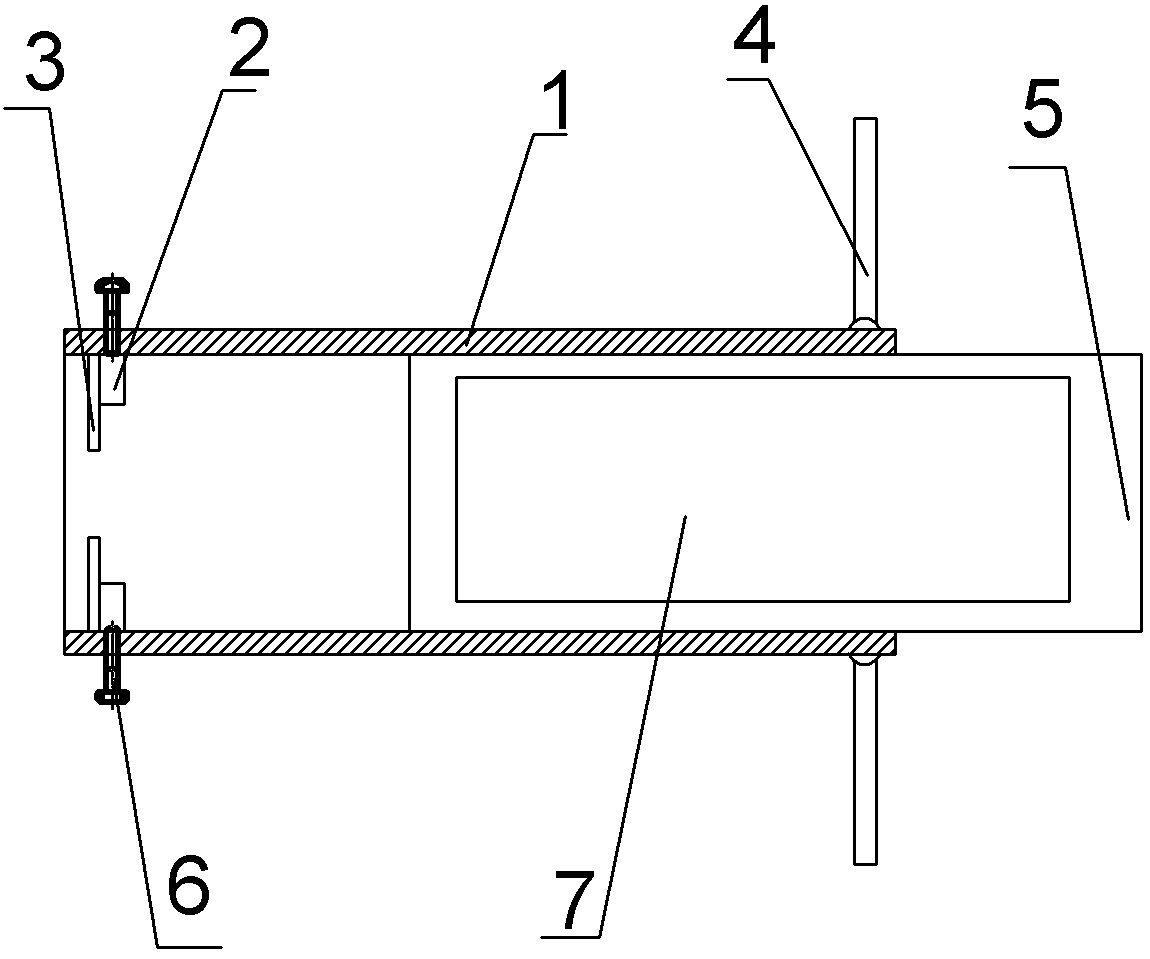

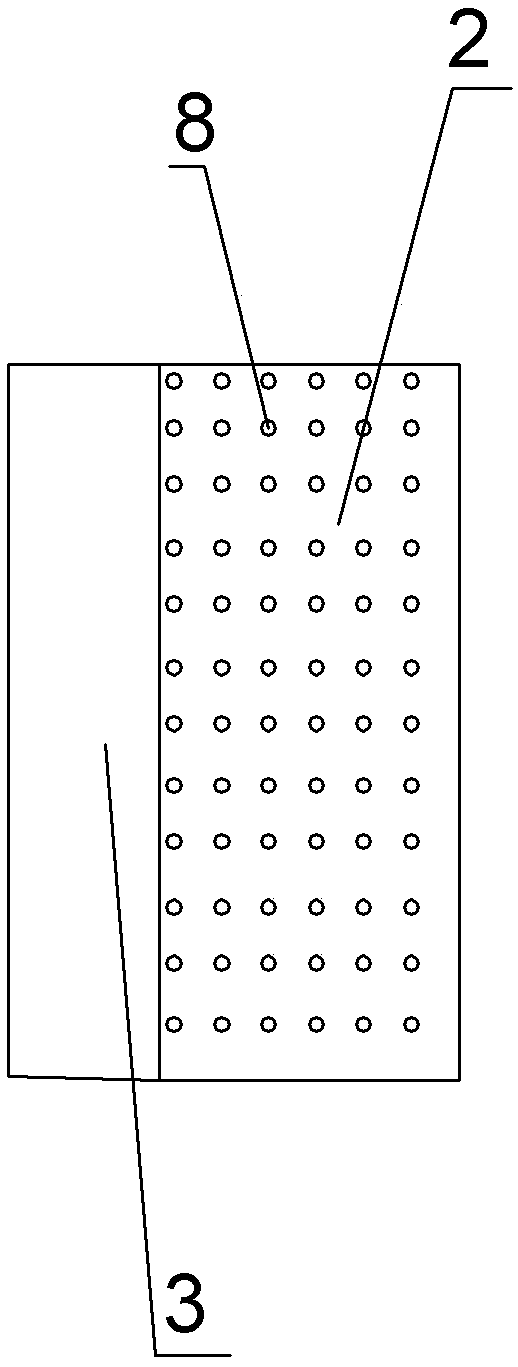

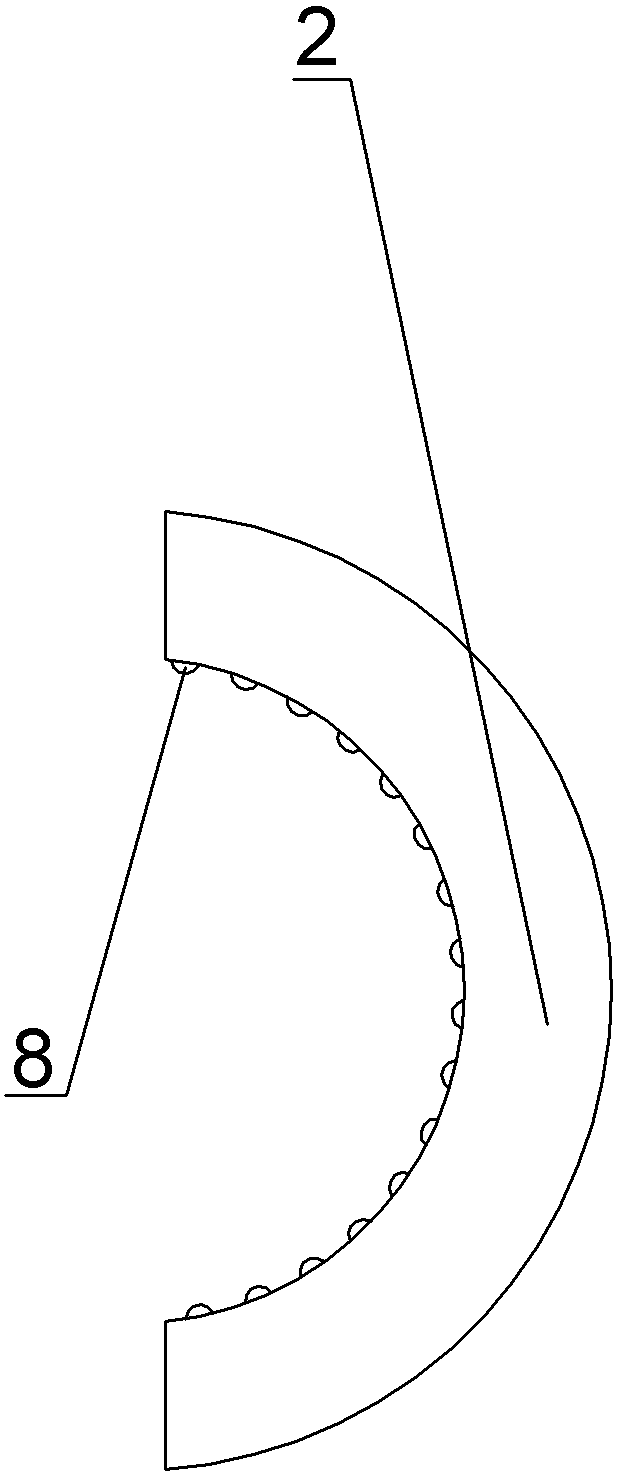

[0016] Embodiment 1: This embodiment is basically as appended Figure 1-3 Shown: a method for disassembling the piston head of a hydraulic cylinder, including a main shaft 5 and a clamping structure, the main shaft 5 is provided with threads, and the clamping structure includes a fixing part 1 and two claws 2, and the two claws 2 and the fixing part One end of 1 is fixedly connected, the fixing part 1 is threadedly connected with the main shaft 5, and the cross section of the claw 2 is semi-circular; the claw 2 is connected with the fixing part 1 through a bolt 6, and a plurality of first fixing blocks 3 are arranged on one side of the claw 2 , The inner surface of the jaw 2 is provided with a plurality of protrusions 8, the main shaft 5 is provided with a magnetic part 7, and the fixing part 1 is made of a metal material, which is iron in this embodiment. The other end of the fixing part 1 is provided with a handle 4, and the fixing part 1 is rotated by the handle 4, which is...

Embodiment 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that there is a groove in the claw 2, and the second fixing block 11, the fixing column 10 and the spring 9 are arranged in the groove, and the second fixing block 11 is located in the groove It is fixedly connected with one end of the spring 9, and the other end of the spring 9 is fixedly connected with the fixed post 10. In this way, when the fixing part 1 is rotated, the fixing column 10 contacts and rotates with the piston head, and the force of the claw 2 on the piston head is increased, and the piston head is clamped tighter and tighter, which is convenient for disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com