A method for robot precision calibration

A robot and precision technology, applied in the field of robots, can solve problems such as poor robot calibration accuracy, and achieve the effects of simple operation, low cost, and improved robot accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

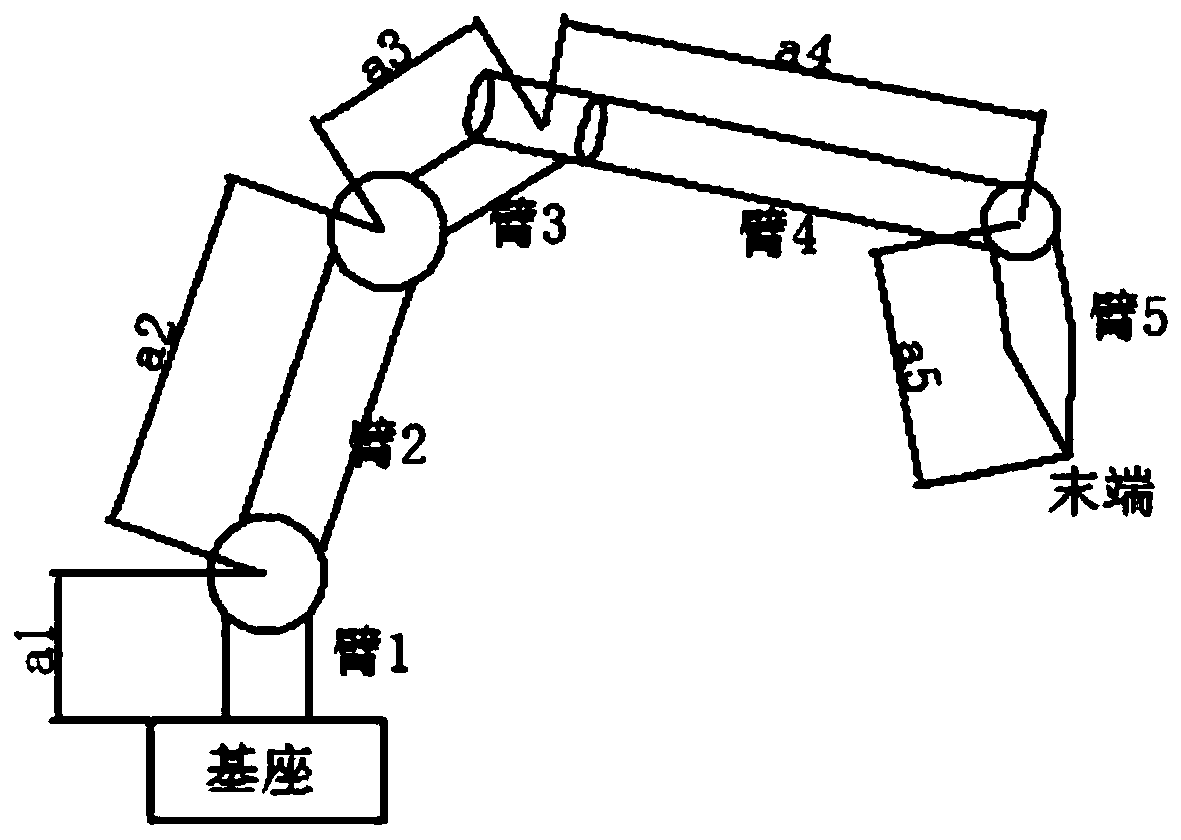

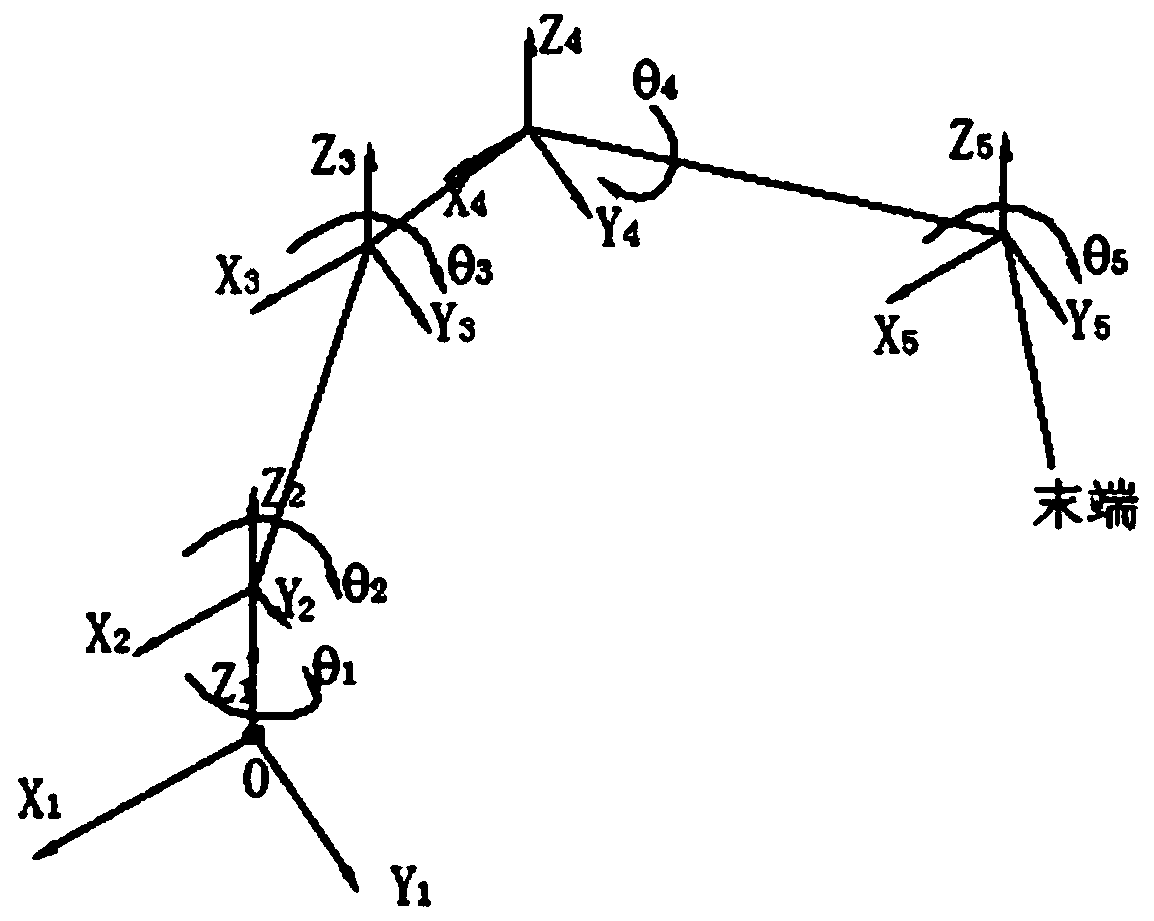

[0028] see Figure 1~2 , the method for robot accuracy calibration includes the following steps:

[0029] 1) Use CNC processing technology to process a rectangular box with a machining accuracy of 0.01mm. Carve coordinate points on the surface of the rectangular box, and use the intersection of any three sides of the box as the coordinate origin to establish a basic coordinate system. The robot is set in the basic coordinate system through the base, and encoders are installed at each joint of the robot. Each encoder is connected to the data acquisition card through the data bus. position in the coordinate system.

[0030] 2) Specify a theoretical reference coordinate system for each joint of the robot, and use the D-H notation to model the robot. The motion pose of each joint is determined by four kinematic parameters: the angle θ between adjacent links; The distance d between rods; the distance a between adjacent joints; the angle α between adjacent joint axes.

[0031] 3)...

Embodiment 2

[0053] The robot in this embodiment can have six axes or more, and the above method can also be used for calibration.

Embodiment 3

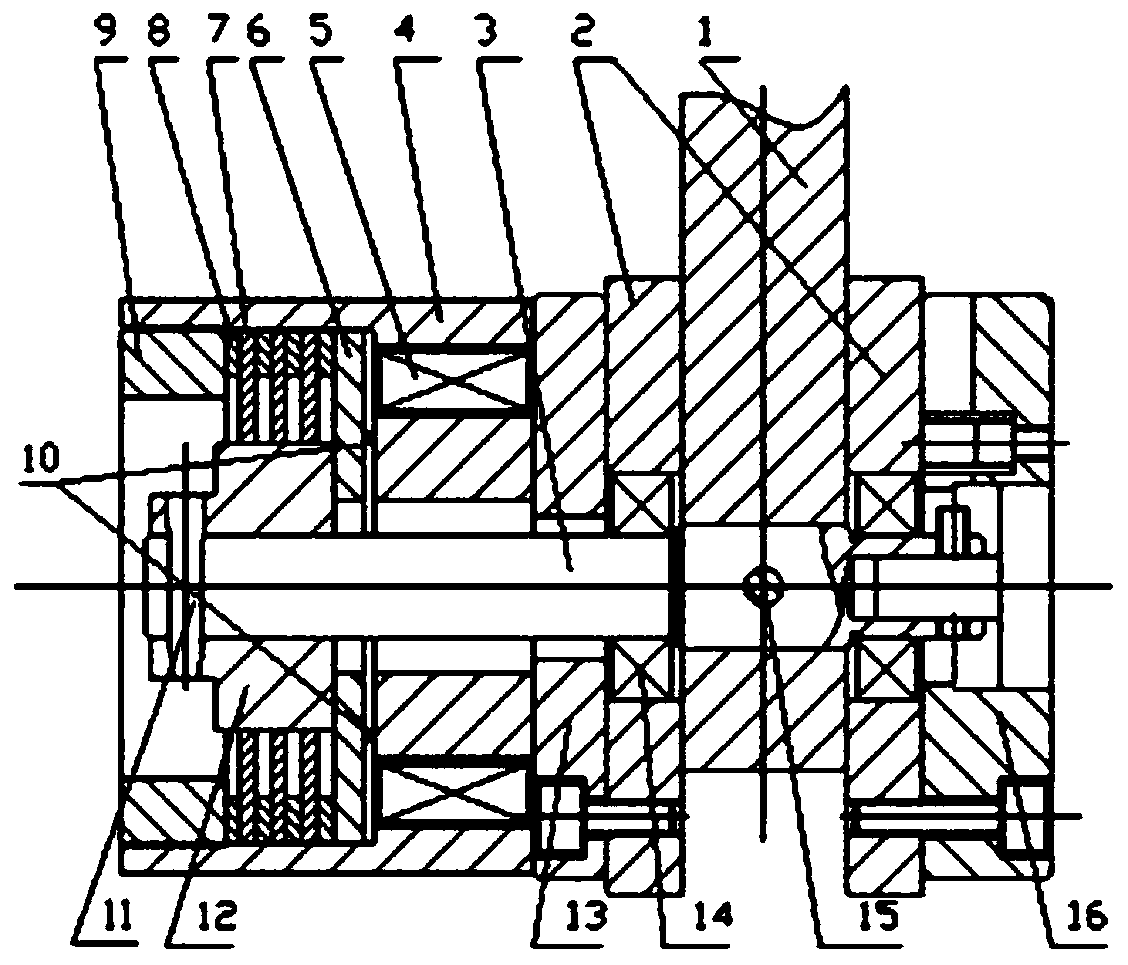

[0055] see image 3 , in order to further ensure the accuracy of robot precision calibration, this embodiment installs an electromagnetic clutch at the joint of the adjacent mechanical arm of the robot. The electromagnetic clutch includes a fixed arm 2, a rotating arm 1, a rotating shaft 3 and a clutch body, and the rotating arm 1. The cylindrical pin 15 is fixedly connected to the rotating shaft 3. The rotating shaft 3 and the fixed arm 2 are set to rotate relative to each other. The clutch body is connected between the fixed arm 2 and the rotating shaft 3 and controls the rotation and stop of the rotating shaft 3. Two adjacent Two mechanical arms are connected to the rotating arm 1 and the fixed arm 2 respectively, and the rotating shaft 3 is locked on the fixed arm 2 by using the clutch body, and then the rotating arm 1 is locked. The structure is simple, the operation is easy, the cost is low, and the precision of the robot is greatly improved. The two fixed arms 2 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com