Integrated concrete laboratory mixing station

A concrete and laboratory technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of laborious mixing effect, uncontrollable process, small number of samples, etc., to ensure accuracy and precision, improve accuracy accuracy and precision, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

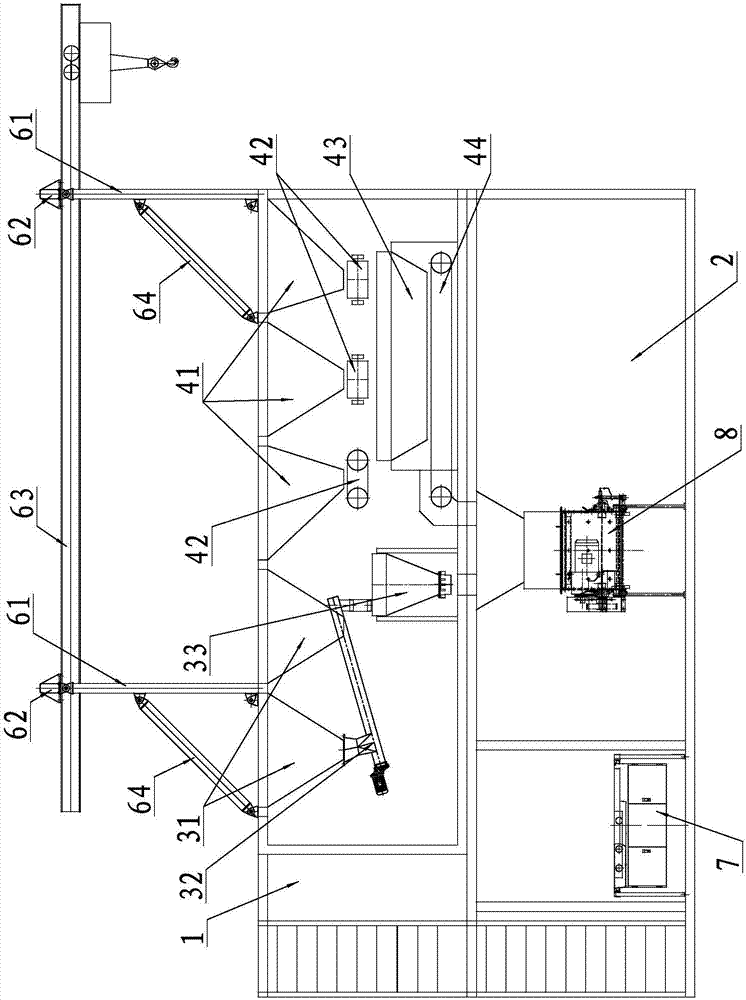

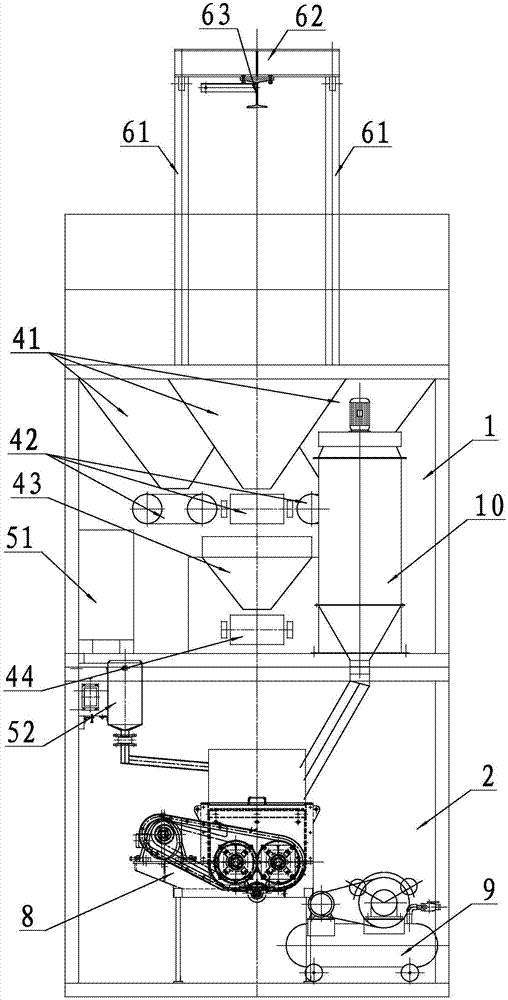

[0036] like figure 1 As shown, an integrated concrete laboratory mixing plant includes an upper box 1 and a lower box 2, the upper box 1 is provided with a powder unit and an aggregate unit, and the top of the upper box 1 is set There is a material lifting unit, and the lower box 2 is provided with a liquid material unit, a control unit 7 and a mixer 8 .

[0037] like figure 1 As shown, the powder unit includes a powder bin 31, a screw conveyor 32 and a powder metering scale 33. Due to the need to use multiple powders in the proportioning experiment, the number of the powder bins 31 is several, and the lower end of the powder bins 31 is provided with a pneumatic valve for controlling opening and closing, so The powder silo 31 is connected to the powder metering scale 33 through a screw conveyor 32 .

[0038] like figure 1 As shown, the aggregate unit includes several aggregate bins 41, and the lower end of each aggregate bin 41 is respectively provided with a first belt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com