External-wall elastic coating with reflective insulation effect and preparation method of external-wall elastic coating

A technology of elastic coating and heat insulation effect, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., it can solve the problems of dust bacteria and mold growth, low resistance to fouling, and difficulty in external insulation. , to achieve the effect of strengthening energy saving and environmental protection, and improving the resistance of exterior walls to fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

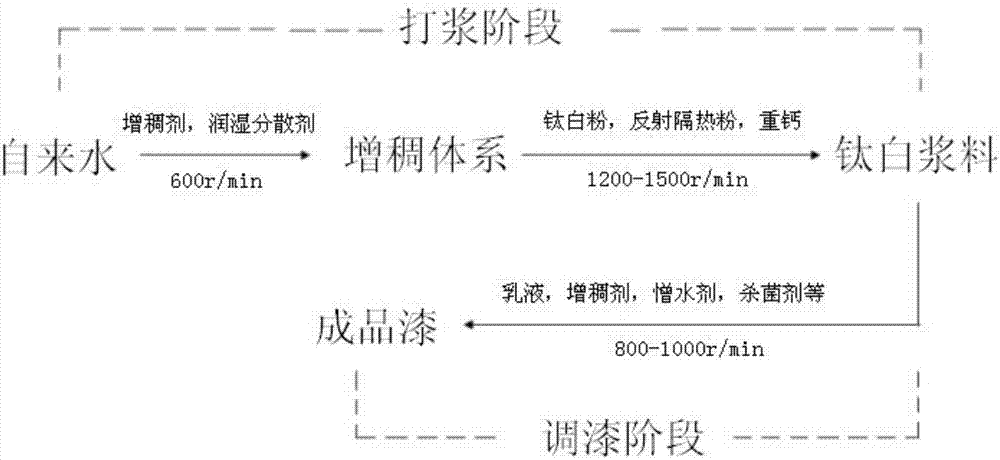

Method used

Image

Examples

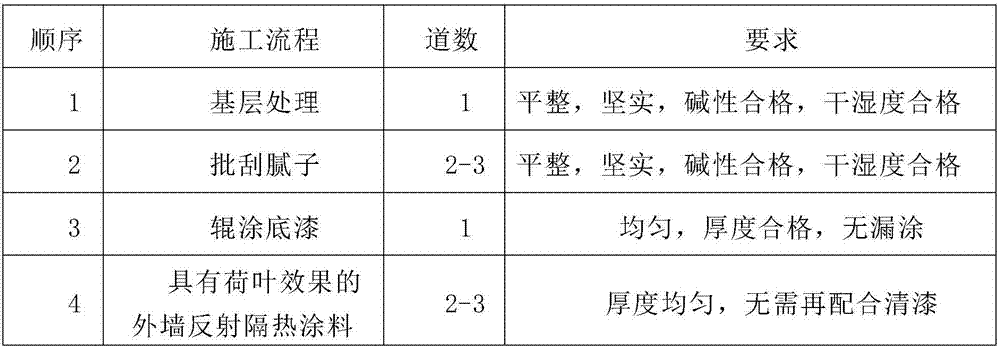

Embodiment Construction

[0018] An elastic coating for external walls with reflection and heat insulation effect, characterized in that the elastic coating consists of 15.0-25.0% of water, 0.2-0.3% of cellulose, 0.1-0.2% of pH regulator, 0.2-0.5% of defoamer, Wetting agent 0.2-0.3%, dispersant 0.4-0.6%, ethylene glycol 1.5-2.5%, film-forming aid 1.0%-1.5%, titanium dioxide 5.0-20.0%, reflective insulation powder 7.0-10.0%, heavy calcium 15.0-20.0%, elastic acrylic emulsion 30.0-40.0%, water repellent 4.0-6.0%, bactericide 0.5-1.0%, alkali swelling thickener 0.3-0.5%, polyurethane thickener 0.3-0.5%.

[0019] The acrylic emulsion in this example is a film-forming substance, and it is a silicone-modified elastic acrylic emulsion with a glass transition temperature of -15°C. Under the condition of maintaining excellent elasticity, it can improve the anti-sticking effect of the paint film, and the dosage is 30.0-40.0%.

[0020] The water-repellent agent in this embodiment is a wax emulsion, which has exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com