High-penetrability and low-surface treatment anti-corrosion coating

A technology of low surface treatment and anti-corrosion coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of reducing protective performance, not belonging to protective anti-corrosion coatings, and easy aging, so as to reduce coating powder The effects of chemical and performance reduction, excellent weather resistance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

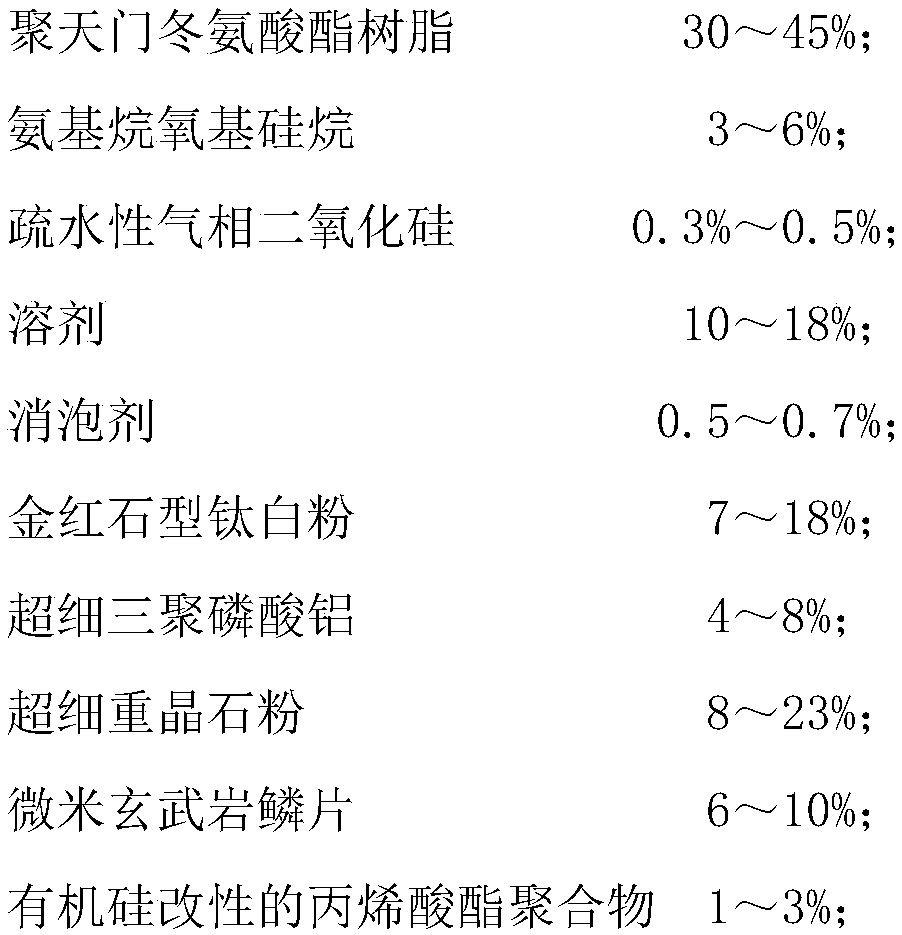

[0026] (1) A kind of anticorrosion coating with high permeability and low surface treatment, containing A component and B component, the weight percent of each raw material in the described A component is:

[0027] 30% of polyaspartic acid ester resin, described polyaspartic acid ester resin is the resin of low viscosity, solvent-free, with secondary amino group, and its NH equivalent is 250~300; Can adopt the trade mark ( Or model) is the polyaspartate resin of F421.

[0028] Aminoalkoxysilane 6%, the aminoalkoxysilane is a reactive bifunctional silane-primary amino group and / or a hydrolyzable ethoxysilyl group, which can be used by Momentive High-tech Materials (China) Co., Ltd. The A-1120 aminosilane coupling agent product produced, this is a kind of reactive bifunctional silane coupling agent, its reactivity duality makes it can be used as crosslinking agent, also can be used as the coating of the present invention Adhesion promoter.

[0029] Hydrophobic fumed silica 0.3...

Embodiment 2

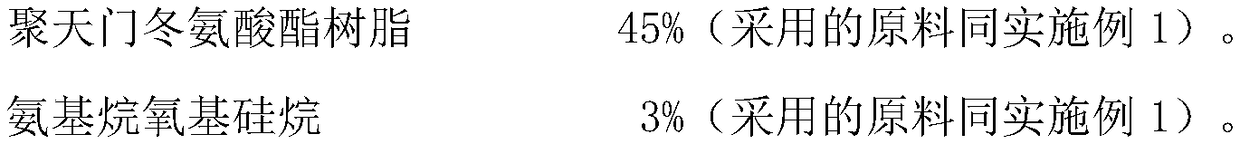

[0051] (1) A kind of anticorrosion coating with high permeability and low surface treatment, containing A component and B component, the weight percent of each raw material in the described A component is:

[0052]

[0053]

[0054] The B component is an isocyanate resin, wherein:

[0055] Hexamethylene diisocyanate resin 70% (the raw material that adopts is with embodiment 1).

[0056] Diphenylmethane diisocyanate 20% (the raw material that adopts is with embodiment 1).

[0057] Solvent 10% (the raw material that adopts is with embodiment 1).

[0058] (2) The preparation method (with embodiment 1) of described high permeability low surface treatment anticorrosion paint.

[0059] (3) The using method of the high permeability low surface treatment anticorrosion coating

[0060] Before painting, the A component and the B component are mixed in a weight ratio of A:B=100:25.

Embodiment 3

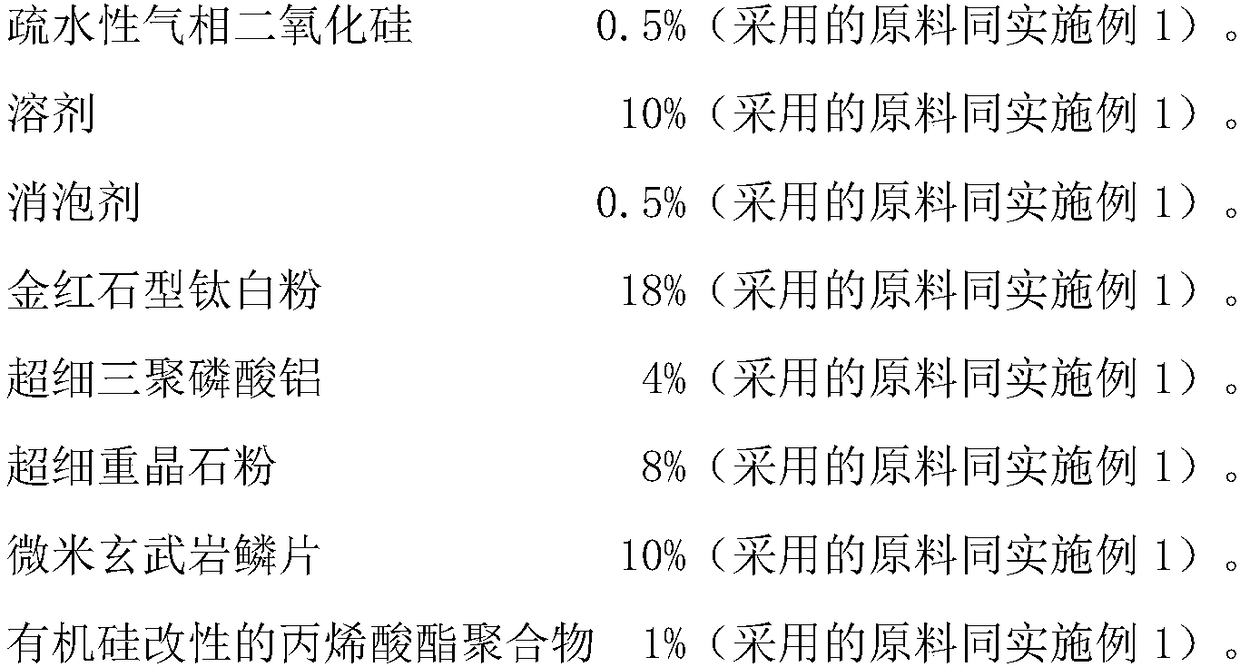

[0062] (1) A kind of anticorrosion coating with high permeability and low surface treatment, containing A component and B component, the weight percent of each raw material in the described A component is:

[0063]

[0064] Component B is isocyanate resin

[0065] Hexamethylene diisocyanate resin 75% (the raw material that adopts is with embodiment 1).

[0066] Diphenylmethane diisocyanate 10% (the raw material that adopts is with embodiment 1).

[0067] Solvent 15% (the raw material that adopts is with embodiment 1).

[0068] (2) The preparation method (with embodiment 1) of described high permeability low surface treatment anticorrosion paint.

[0069] (3) The using method of the high permeability low surface treatment anticorrosion coating

[0070] Before painting, the A component and the B component are mixed in a weight ratio of A:B=100:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com