Water in water multicolor reflective thermal-insulation paint, and preparation method thereof

A reflective heat-insulating coating, water-in-water technology, applied in the direction of reflective/signal paint, anti-fouling/underwater paint, coating, etc., can solve the problem that the reflective heat-insulation performance cannot be maintained for a long time, and the reflective heat-insulation performance cannot be achieved by colorful coatings etc., to achieve the effects of reducing entry and accumulation, improving durability and stain resistance, and dense coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

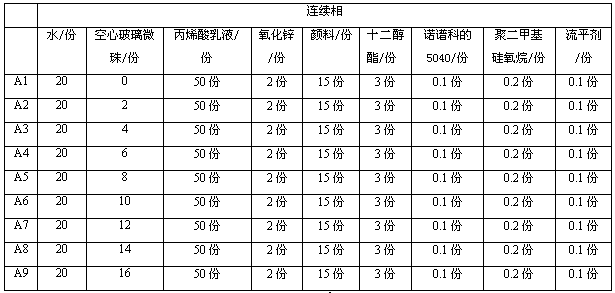

[0040] S1, Weigh the following raw materials: 400g of water, 160g of hollow glass microspheres (5020, Zhejiang Haiyue New Material Co., Ltd.), 1000g of acrylic emulsion, 30g of zinc oxide, 360g of pigment, 60g of lauryl alcohol ester, 5040 of Nuopuke 8g, polydimethylsiloxane 4g, leveling agent (RJ-2020, Shanghai from Zero Chemical Co., Ltd.) 2g;

[0041] S2. Add the water in S1, acrylic emulsion and Noble's 5040 into the first reactor in turn at a speed of 300 rpm, and disperse for 2 minutes. Add pigments, zinc oxide, and disperse for 15 minutes at a speed of 1000 rpm. minute, add hollow glass microspheres, lauryl alcohol ester, polydimethylsiloxane and leveling agent successively at 600 rpm, and stir for 15 minutes to obtain a continuous phase;

[0042] S3. Weigh the following raw materials: 1200g of water, 3g of hydroxyethyl cellulose, 20g of coconut oil fatty acyldiethanolamine, and 30g of hollow ceramic powder;

[0043]S4, add water and coconut oil fatty acid acyldiethano...

Embodiment 2

[0046] S1, Weigh the following raw materials: 600g of water, 240g of hollow glass beads (5020, Zhejiang Haiyue New Material Co., Ltd.), 800g of acrylic emulsion, 20g of zinc oxide, 300g of pigment, 40g of lauryl alcohol ester, 5040 of Noble 2g, ethylene glycol siloxane 10g, leveling agent (RJ-2020, Shanghai from Zero Chemical Co., Ltd.) 4g;

[0047] S2. Add the water in S1, acrylic emulsion and Noble's 5040 into the first reactor in turn at a speed of 500 rpm, and disperse for 3 minutes. Add pigments, zinc oxide, and disperse at a speed of 1200 rpm. For 10 minutes, add hollow glass microspheres, lauryl alcohol ester, ethylene glycol siloxane and leveling agent sequentially at 600 rpm, and stir for 10 minutes to obtain a continuous phase;

[0048] S3. Weigh the following raw materials: 1600g of water, 4g of hydroxyethyl cellulose, 30g of coconut oil fatty acyldiethanolamine phosphate, and 40g of hollow ceramic powder;

[0049] S4, add water and coconut oil fatty acid acyldieth...

Embodiment 3

[0052] S1, Weigh the following raw materials: 700g of water, 200g of hollow glass microspheres (5020, Zhejiang Haiyue New Material Co., Ltd.), 1200g of acrylic emulsion, 40g of zinc oxide, 400g of pigment, 100g of lauryl alcohol ester, 5040 of Nuopuke 10g, 6g of fluorosilicone, 3g of leveling agent (RJ-2020, Shanghai from Zero Chemical Co., Ltd.);

[0053] S2. Add the water in S1, acrylic emulsion and Noble’s 5040 into the first reactor sequentially at a speed of 400 rpm, and disperse for 3 minutes. Add pigments, zinc oxide, and disperse at a speed of 1100 rpm. For 15 minutes, add hollow glass microspheres, lauryl alcohol ester, fluorosiloxane and leveling agent in sequence at 400 rpm, and stir for 12 minutes to obtain a continuous phase;

[0054] S3. Weigh the following raw materials: 1400g of water, 2g of hydroxyethyl cellulose, 40g of coconut oil fatty acyldiethanolamine phosphate, and 20g of hollow ceramic powder;

[0055] S4, add water and coconut oil fatty acid acyldiet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com