Low-alcohol chuzhou chrysanthemum leaching liquor and production method thereof

A production method, the technology of chrysanthemum, which is applied in the field of food processing, can solve the problems of ineffective extraction of chrysanthemum, hidden dangers to consumers' health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Embodiment 1: Production of low-alcohol chrysanthemum leaching wine

[0135] The implementation steps of this embodiment are as follows:

[0136] A. Chuju pretreatment

[0137] Select high-quality chrysanthemum, remove impurities, wash, and dry the cleaned fresh chrysanthemum at a temperature of 60°C for 40 minutes;

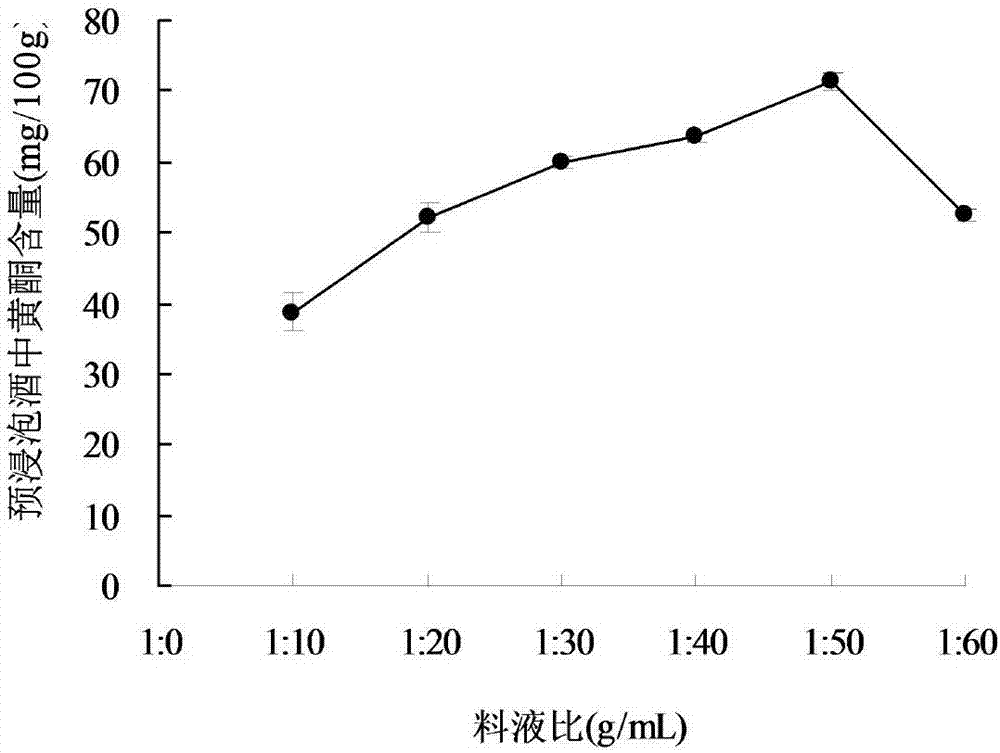

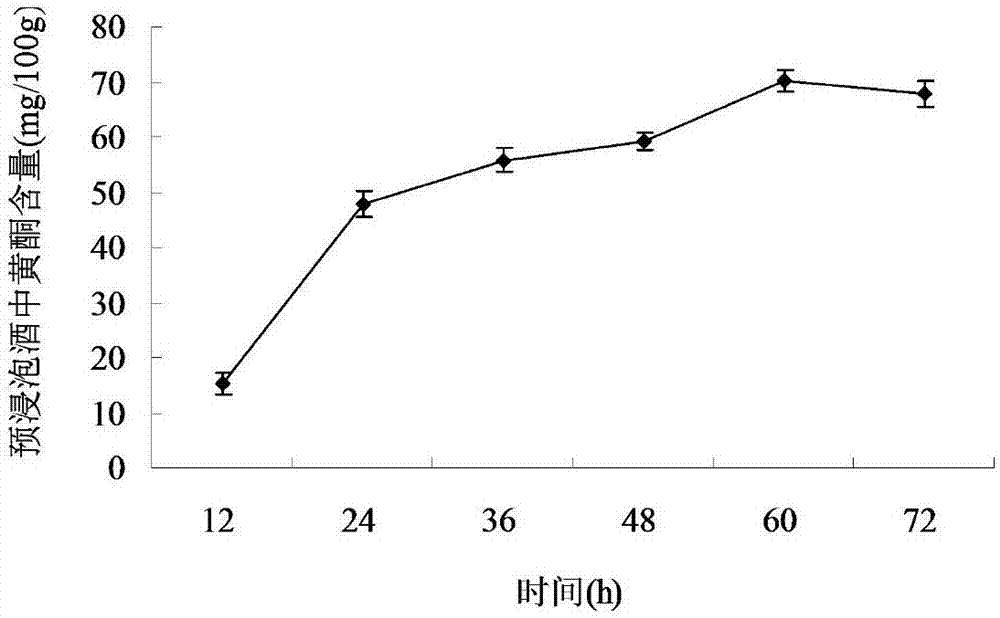

[0138] B. Pre-soak

[0139] According to the ratio of chrysanthemum in grams to base liquor in milliliters of 1:10, add the chrysanthemum obtained in step A to the Wuliangye base liquor, pre-soak and extract at room temperature for 12 hours, and separate to obtain the pre-extraction of chrysanthemum chrysanthemum;

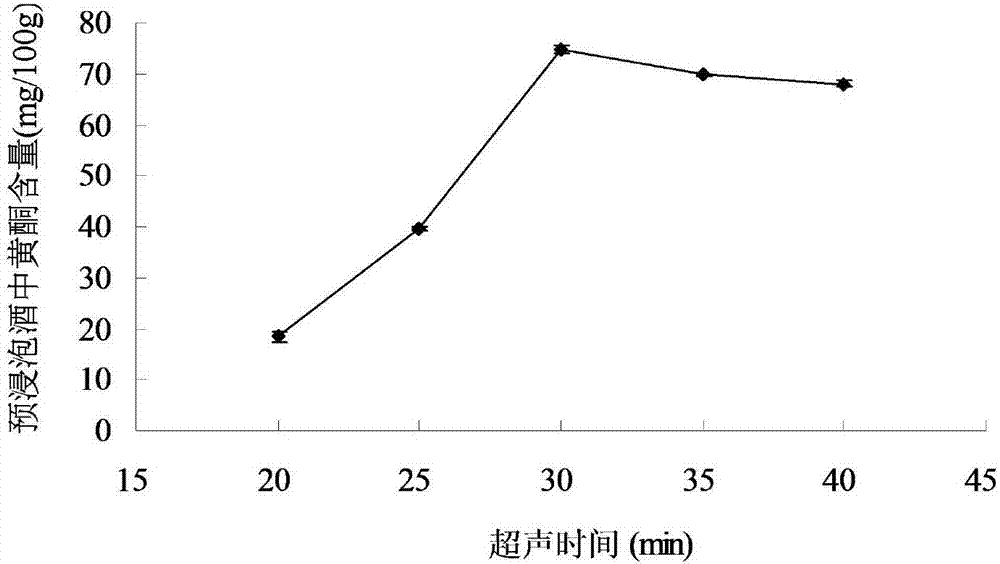

[0140] C. Low temperature ultrasonic extraction

[0141] The chrysanthemum pre-extraction solution obtained in step B was leached in an ice bath for 20 minutes under the condition of a power of 120W by a UWave-1000 type microwave, ultraviolet, and ultrasonic trinity synthetic extraction reaction instrument produced by Shanghai Xinyi Microwav...

Embodiment 2

[0148] Embodiment 2: produce low-alcohol chrysanthemum leaching wine

[0149] The implementation steps of this embodiment are as follows:

[0150] A. Chuju pretreatment

[0151] Select high-quality chrysanthemum, remove impurities, wash, and dry the cleaned fresh chrysanthemum at a temperature of 50°C for 50 minutes;

[0152] B. Pre-soak

[0153] According to the ratio of chrysanthemum in grams to base liquor in milliliters as 1:60, add the chrysanthemum obtained in step A to Sichuan Luzhou-flavor distilled liquor (42°) base liquor, and pre-soak for 72 hours at room temperature; Obtain the chrysanthemum chrysanthemum pre-extraction solution;

[0154] C. Low temperature ultrasonic extraction

[0155] The chrysanthemum chrysanthemum pre-extraction liquid that step B obtains adopts UWave-1000 type microwave · ultraviolet · ultrasonic three-in-one synthetic extraction reaction instrument produced by Shanghai Xinyi Microwave Chemical Technology Co., Ltd. to extract 40 minutes i...

Embodiment 3

[0162] Embodiment 3: Production of low-alcohol chrysanthemum leaching wine

[0163] The implementation steps of this embodiment are as follows:

[0164] A. Chuju pretreatment

[0165] Select high-quality chrysanthemum, remove impurities, wash, and dry the cleaned fresh chrysanthemum at a temperature of 55°C for 45 minutes;

[0166] B. Pre-soak

[0167] According to the ratio of chrysanthemum in grams to base wine in milliliters of 1:40, the chrysanthemum obtained in step A was added to Luzhou Laojiao Tequ base wine, pre-soaked and extracted at room temperature for 48 hours, and pre-prepared chrysanthemum was obtained by separation. Extraction solution;

[0168] C. Low temperature ultrasonic extraction

[0169] The chrysanthemum chrysanthemum pre-extraction solution obtained in step B was extracted in an ice bath for 30 minutes under the condition of power 140W by UWave-1000 type microwave, ultraviolet and ultrasonic trinity synthesis extraction reaction instrument produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com