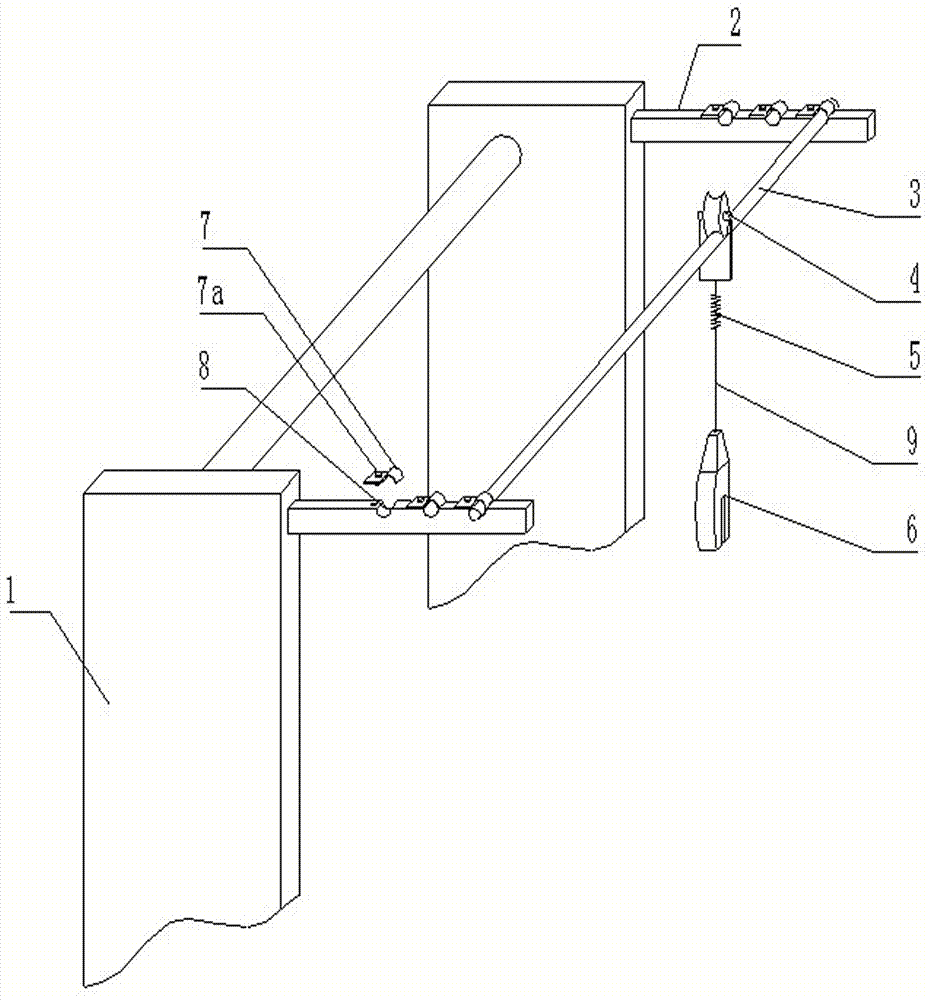

Suspension type cloth inspecting machine broken end sewing device

A cloth inspection machine and hanging type technology are applied in the field of the sewing head device of the hanging cloth inspection machine, which can solve the problems affecting the quality of the cloth seam head and the production safety, easy fatigue, high labor intensity, etc. The effect of low operation and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Before operation, the operator first horizontally adjusts the guide rod 3 into a suitable arc-shaped groove 8, and then fixes the arc-shaped buckles 7 at both ends respectively. When the cloth sewing head is operated, the operator pulls the hand-held sewing machine 6 to move left and right to sew the cloth section. During the operation, the pulley 4 slides left and right along the guide rod 3, and the operator can hold the hand-held sewing machine 6 to easily complete the stitching of the cloth section, and the quality of the seam head is stable. The operating position of the hand-held sewing machine 6 suspended by the spring 5 can be slightly adjusted to meet the needs of operators of different heights.

[0021] The invention has simple structure, extremely light operation load, greatly reduces labor intensity, and allows operators to spare more energy to complete the cloth seam operation of the cloth inspection machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com