Seamless steel bridge deck structure of road bridge and construction method

A steel bridge deck and seamless steel technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of high performance requirements of expansion devices, slow research progress of method 3, and difficult breakthroughs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

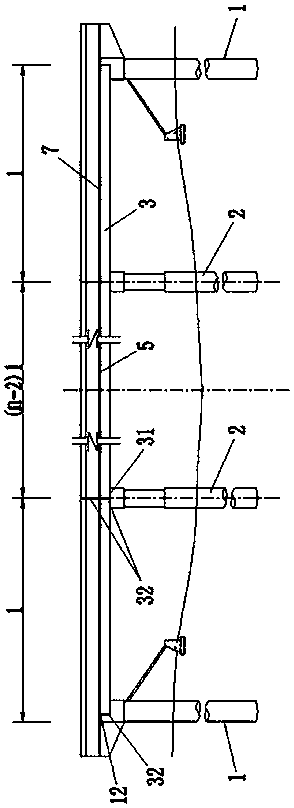

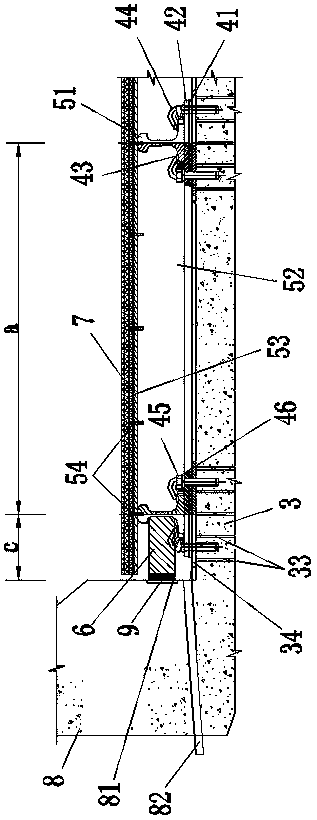

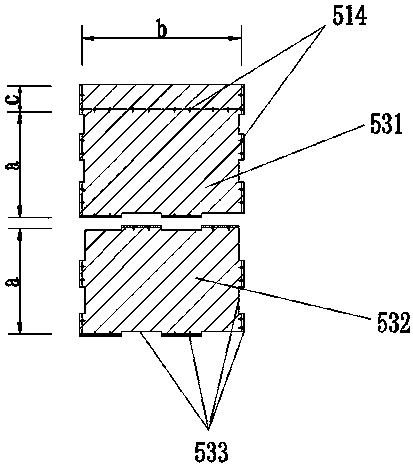

[0090] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

[0091] Such as Figure 1~Figure 7 As shown, 1. Abutment, 11. Slope protection, 12. Abutment steel plate, 2. Bridge pier, 3. Prefabricated beam, 31. Support, 32. Expansion joint, 33. Prefabricated slab steel bar, 34. Prefabricated slab steel plate, 35 .Leveling layer, 4. Fastener, 41. Elastic backing plate, 42. Steel backing plate, 43. Gauge block, 44. Elastic bar, 45. Fastener bolt, 46. Flat washer, 5. Steel bridge deck, 51 .I-beam longitudinal beam, 511. Lower flange, 512. Web plate, 513. Upper flange, 514. Steel panel bolt hole, 52. Steel transverse beam, 53. Steel panel, 531. Steel panel A, 532 .Steel panel B, 533. Concave-convex teeth, 54. Steel panel bolts, 6. Block, 7. Asphalt concrete, 8. Anti-collision guardrail, 81. Guardrail steel plate, 82. Drain pipe, 9. Rubber block.

[0092] Road bridge seamless steel deck structure and construction met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com