Steel bridge recoating device

A coating and steel bridge technology, which is applied to the surface coating liquid device, spray device, bridge, etc., can solve the problems of difficult erection of supports, high risk factor, and large width, so as to prevent vehicle bumps and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

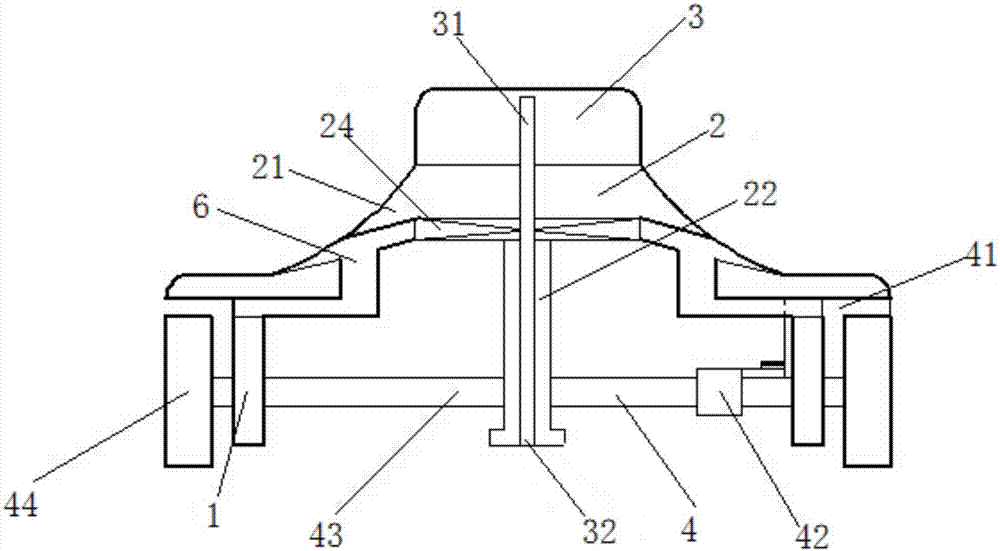

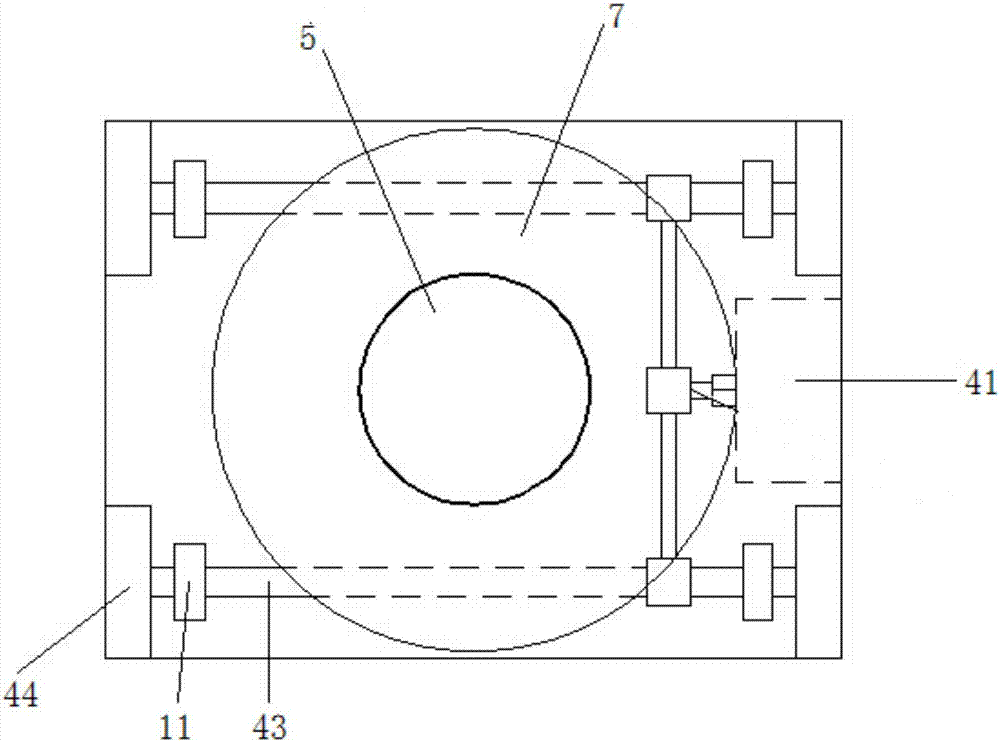

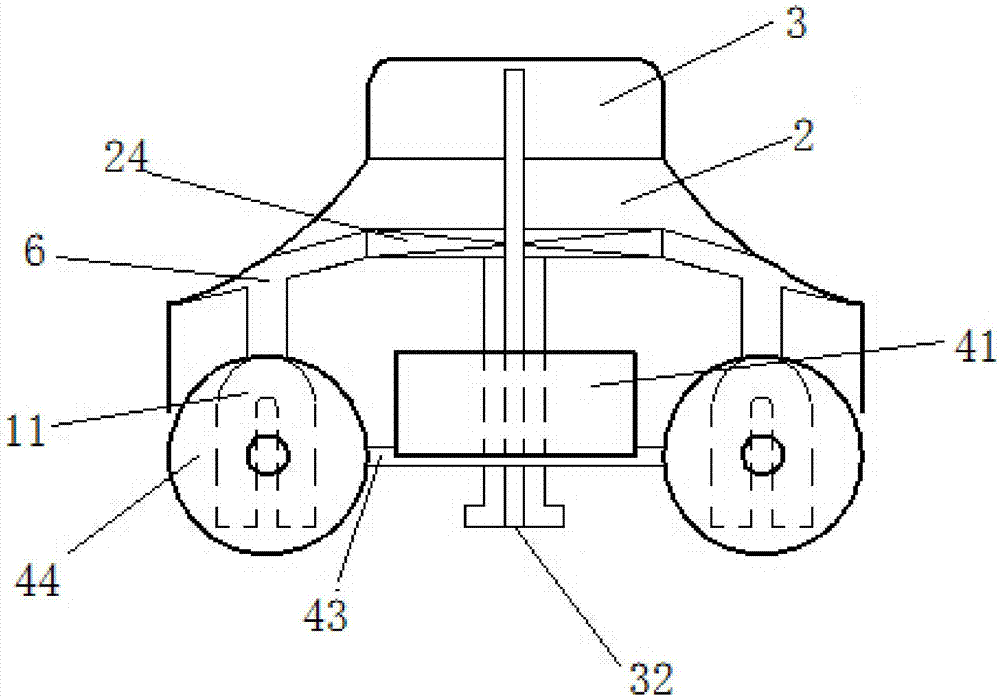

[0034] Such as Figure 1~5 As shown, a steel bridge repainting device includes: a magnetic suction system 1, a cleaning system 2 and a paint spraying system 3; the magnetic suction system 1 is used to adsorb the device on the steel plate at the bottom of the bridge, including four A U-shaped electromagnet 11, in order to maximize the magnetic force, is arranged at the bottom of the device; the cleaning system 2 and the painting system 3 are all arranged at the top of the device, and are respectively used for cleaning the steel plate at the bottom of the bridge and painting after cleaning. The system 2 is arranged on the top of the device suspension 6, and the paint spraying system 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com