Wood floor for stadium and production process thereof

A production process and technology of wood flooring, applied in the direction of elastic flooring, wood processing equipment, manufacturing tools, etc., can solve problems such as deterioration, affecting the service life of wooden board structures, mildew, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

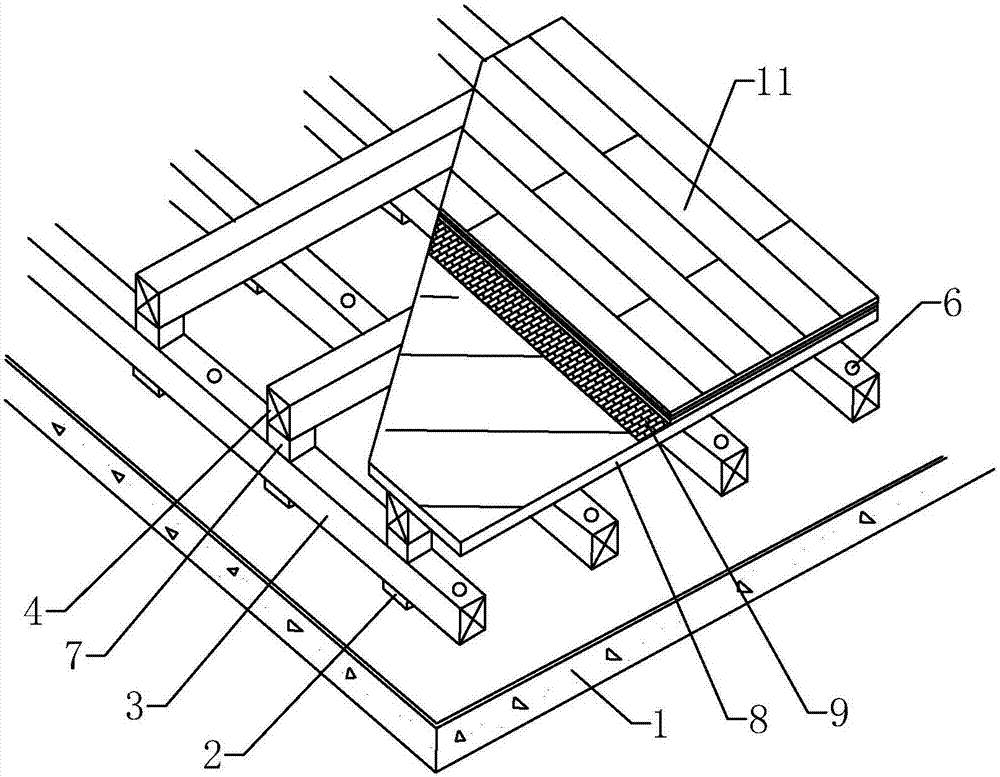

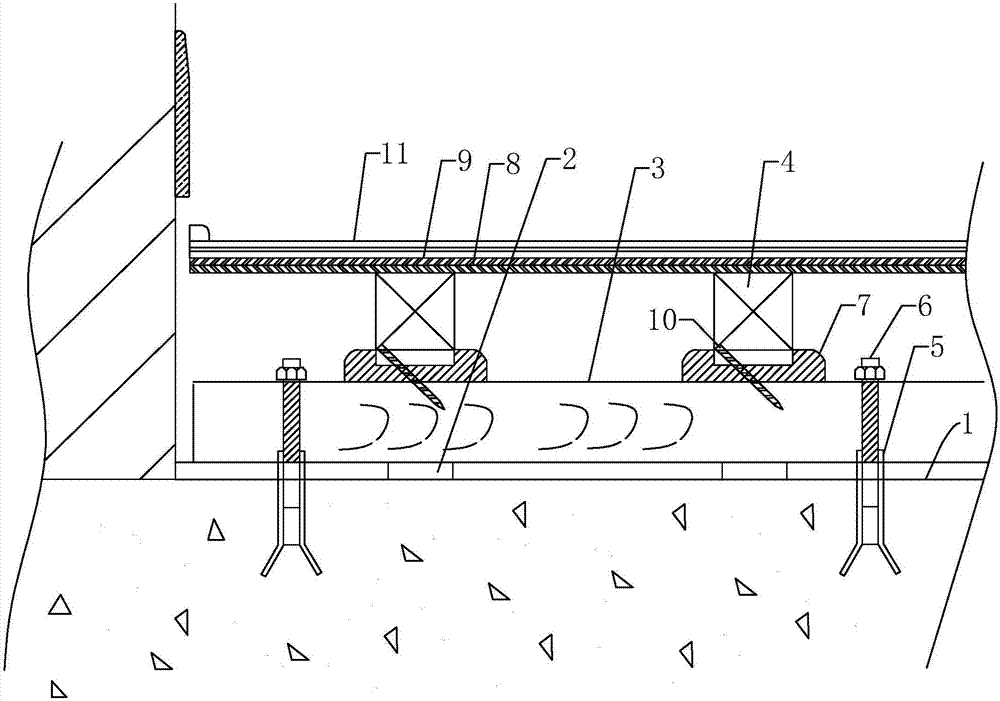

[0060] Embodiment 1: Reference figure 1 and figure 2 , a kind of wooden floor for a stadium, the lower pine keel 3 and the upper pine keel 4 are laid on the foundation 1, the cross-sections of the lower pine keel 3 and the upper pine keel 4 are both 40mm*50mm, the upper pine keel 4 and the lower pine keel 3 are horizontal and vertical Staggered, the middle distance of the upper pine keel 4 is 400mm, the middle distance of the upper pine keel 4 arrangement near the basketball stand is 200mm, the middle distance of the lower pine keel 3 is 400mm, and the overlap between the upper pine keel 4 and the lower pine keel 3 The nodes are supported by 20mm elastic rubber pads 7, while the lower pine keel 3 is supported on the foundation 1 by leveling pads 2, and the center of the leveling pads 2 and the center of the elastic rubber pads 7 are on the same center line.

[0061] Regarding the fixation of the lower pine keel 3: After the foundation 1 is driven into the embedded part 5, th...

Embodiment 2

[0064] Embodiment 2: A production process of wooden floor for stadiums, including maple floor 11 processing technology, keel processing technology, water-resistant plywood 8 processing technology; the specific content of the three processes will be elaborated below.

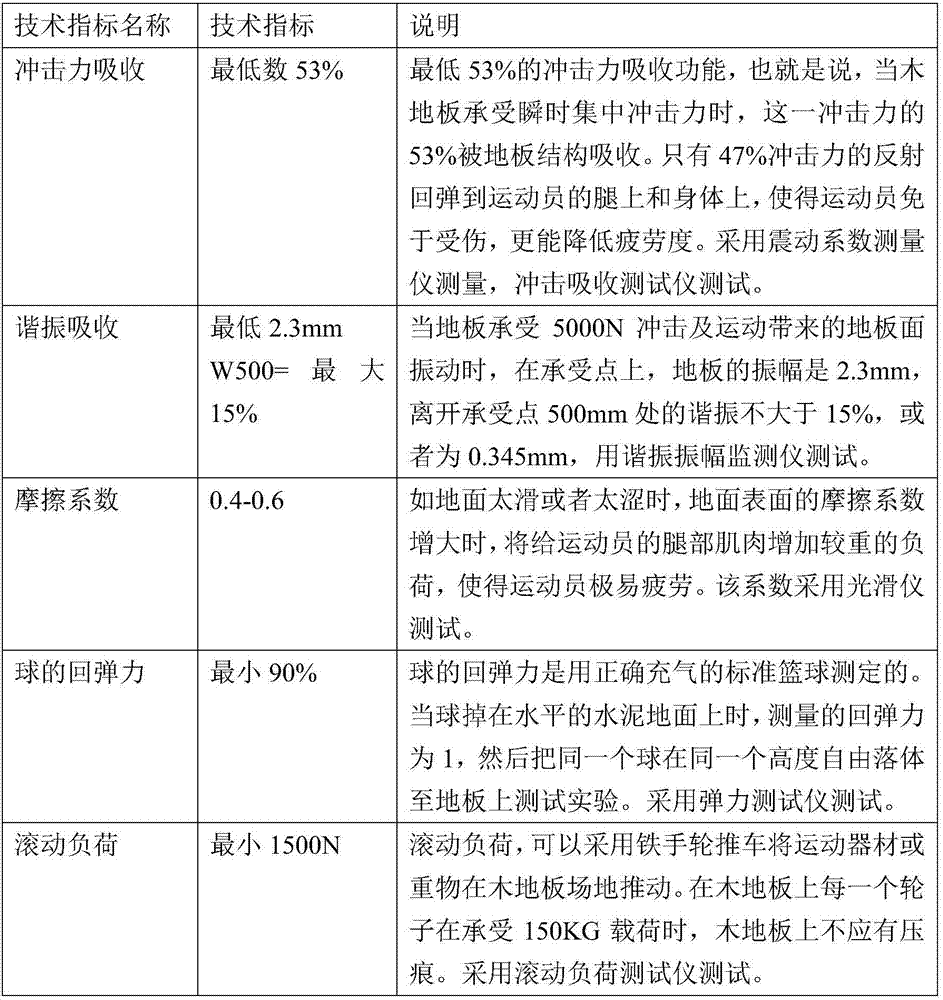

[0065] In order to ensure that the quality of sports wood flooring meets the design requirements and international standards, our company adopts the following standardized operating procedures in accordance with ISO9001 quality system certification and ISO14001 international environmental protection system certification. Maple flooring 11 processing technology includes the following steps:

[0066] Step 1. Select materials, select high-quality first-class round wood, and the diameter of the wood is more than 0.5 meters;

[0067] Step 2, cutting and planing, and processing the round material into a standard material through four-sided sectioning;

[0068] Step 3, steam degreasing, carry out steam degreasing and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com