Soft soil foundation excitation well digging device and construction method thereof

A technology of soft soil foundation and construction method, which is applied in the direction of earth drilling, vibration drilling, drilling equipment and methods, etc., which can solve the problems of high soil quality requirements, affecting the quality of precipitation, and high labor intensity, etc., and achieve the reinforcement effect Obvious, advanced and reliable technology, obvious effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

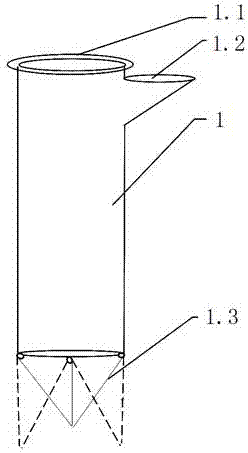

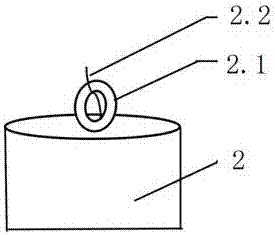

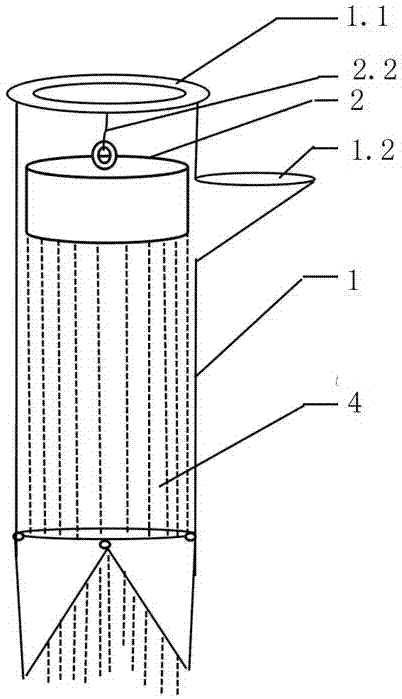

[0048] see Figure 1-Figure 4 , the present invention relates to a kind of soft ground vibration well drilling device, which includes a well drilling steel pipe 1, a vibratory hammer, a pressurizing hammer 2 and a dewatering well pipe 3;

[0049] The well-drilling steel pipe 1 is vertically arranged, the upper end of the well-drilling steel pipe 1 is fixedly connected with a flange 1.1, the inner diameter of the well-drilling steel pipe 1 and the middle hole size of the flange 1.1 are ≥500mm, and the well-drilling steel pipe 1 A feeding port 1.2 is provided on one lateral side of the upper end of the steel pipe, and the lower end of the well-drilling steel pipe 1 is connected with an openable and closable pipe tip leaflet 1.3 through a hinge. The length of the well-drilling steel pipe is determined according to the geological report and the well depth required for the design. The inner diameter of the well-drilling steel pipe 1 is greater than the outer diameter of the dewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com