Two-arm and two-basket steel arch mounting machine and steel arch construction method used for tunnel

A steel arch and installation machine technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of low working efficiency of single-arm arch installation machines, unsuitable for domestic construction conditions, inconvenient use, etc., to reduce personnel. Labor intensity, improving construction efficiency and construction accuracy, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

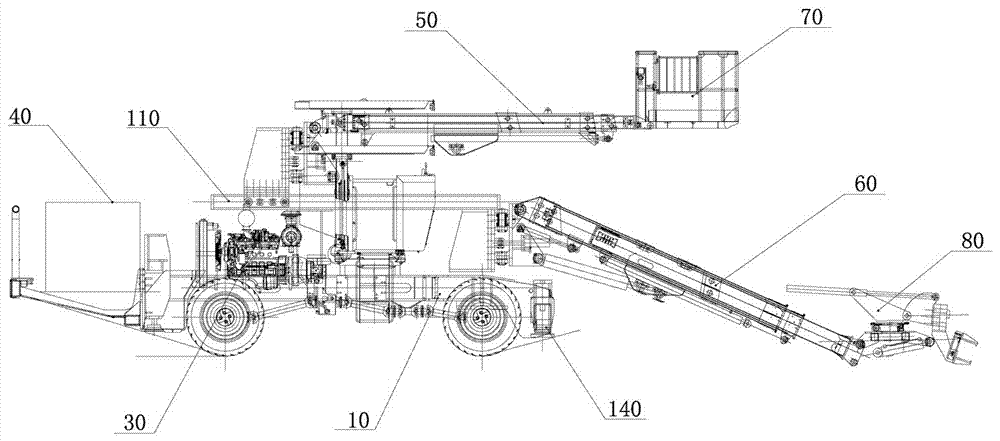

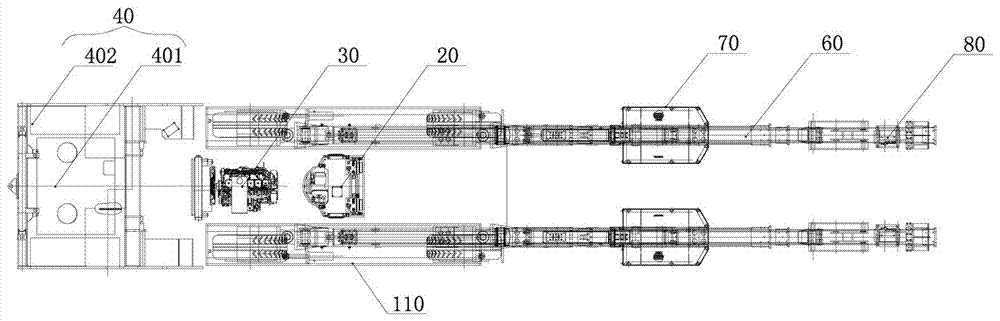

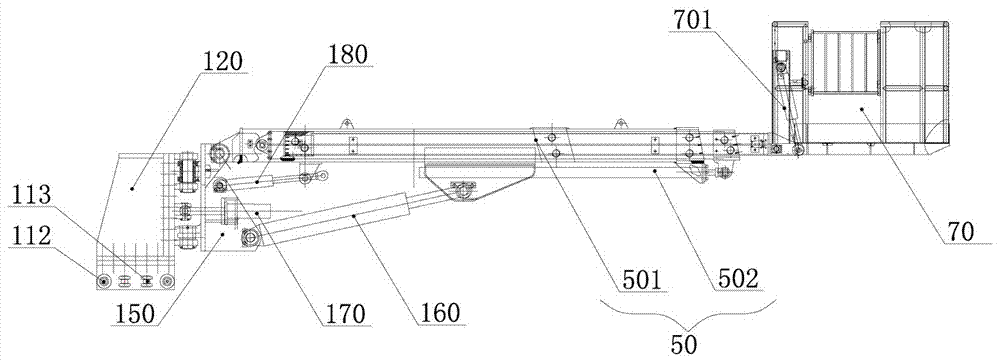

[0029] see Figure 1-Figure 5 , a steel arch installation machine with two arms and two baskets for a tunnel, comprising a chassis 10, a driver's cab 20 arranged on the chassis, a power system 30 and a control system 40; two sliding frames 110 are arranged side by side on the chassis 10, two Sliding supports 120 are arranged on the sliding frame 110 for matching and sliding, and sliding grooves 111 are arranged on both sides of the sliding frame 110, and matching sliding cards are arranged on both sides of the bottom of the sliding supporting seat 120 and are arranged in the sliding grooves. Support roller 112 and guide roller 113 in 111.

[0030] Each of the sliding support bases 120 is provided with a hanging basket arm 50, the hanging basket arm 50 can be telescopically adjusted along the length direction, and the hanging ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com