Working face supporting and withdrawing robot and working method thereof

A working face and robot technology, which is applied to earth-moving drilling, pillars/supports, mining devices, etc., can solve the problems of low working face retraction efficiency, high labor intensity of workers, and increased safety hazards during retraction work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

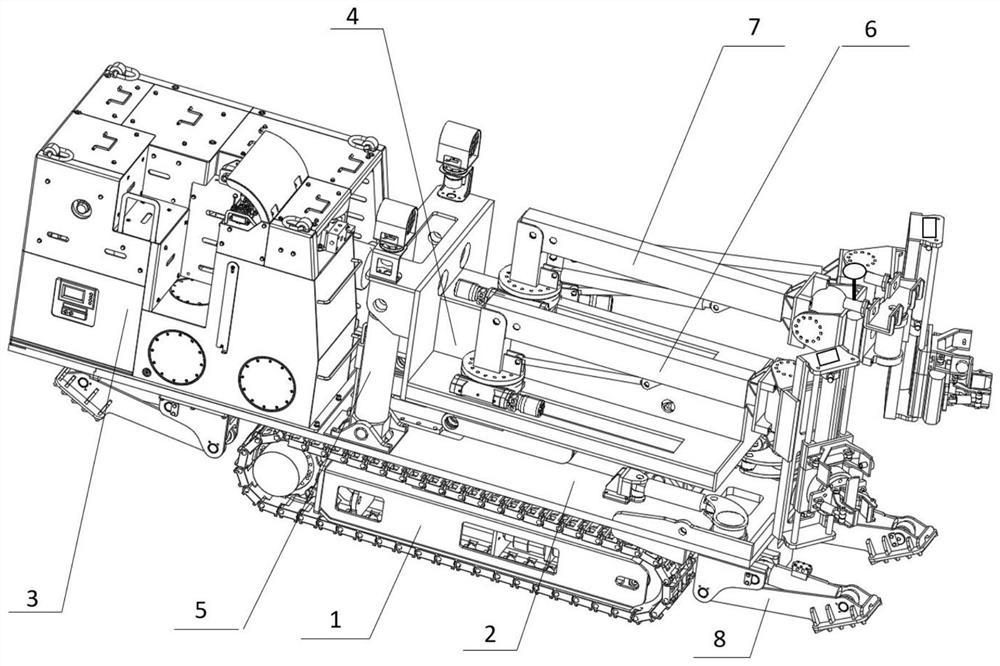

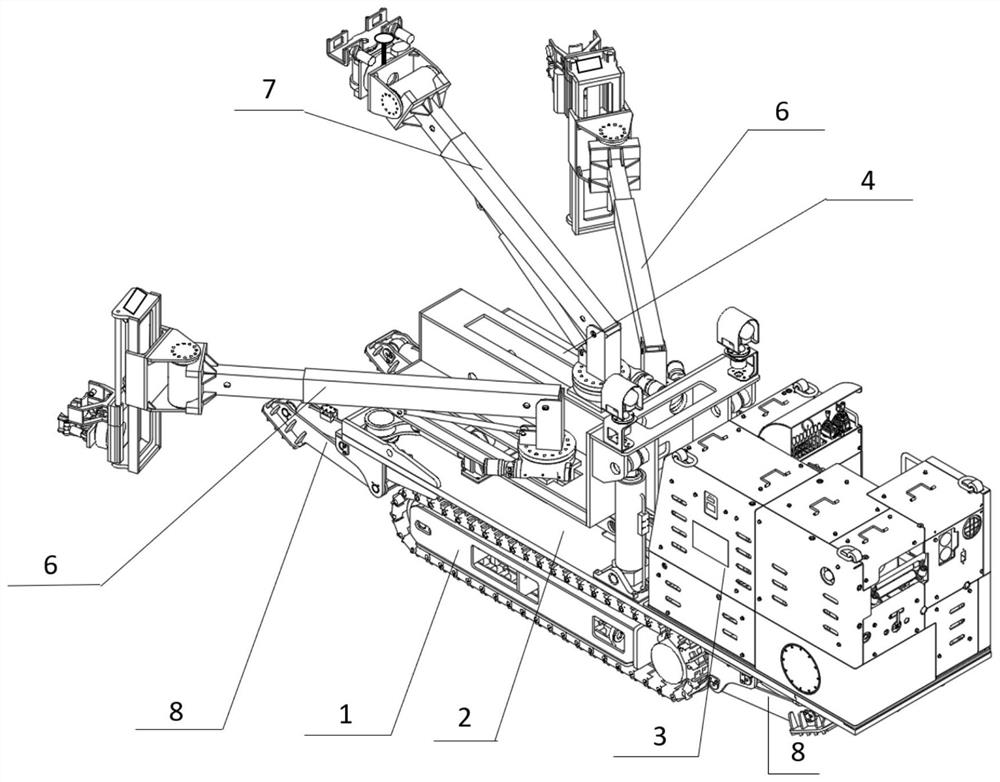

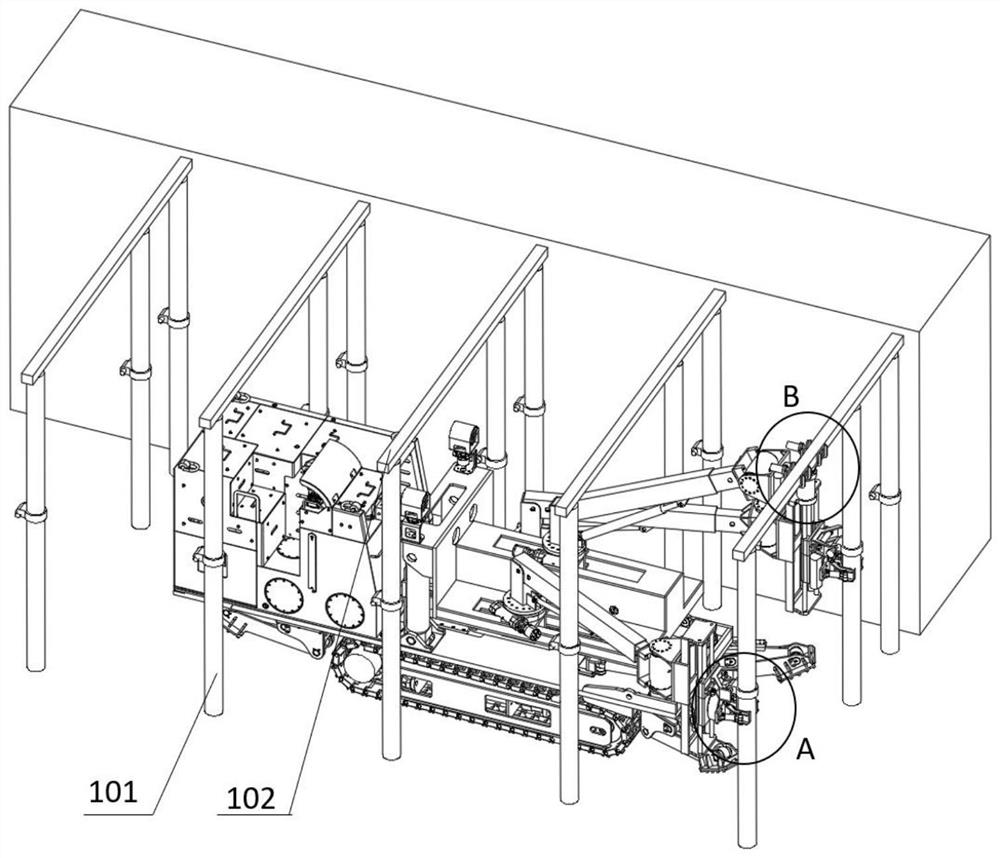

[0048] Such as Figure 1-10 As shown, a working face support retraction robot is used to retract the single hydraulic prop 101 and beam 102 of the working face support, and transport them to the designated transport vehicle outside the mine; wherein, the single hydraulic prop 101 is vertical There are multiple sets, the two ends of the beam 102 are respectively connected to the tops of the two single hydraulic props 101; the working face support retraction robot includes a walking mechanism 1, a chassis 2, a power centralized station 3, an installation base 4, a lifting Mechanism 5, column retraction mechanism 6, beam retraction mechanism 7 and support leg mechanism 8.

[0049] Among them, the walking mechanism 1 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com