Engine air filter element with hollow fiber film

An air filter and fiber membrane technology, applied in engine components, machines/engines, combustion air/combustion-air treatment, etc., can solve the problems of air filter failure, high maintenance workload and cost, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

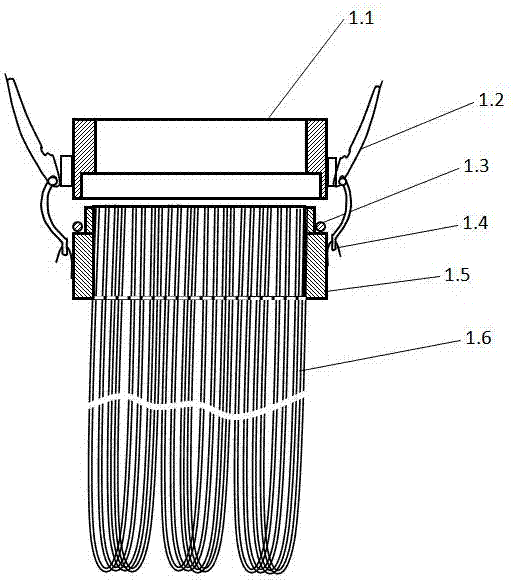

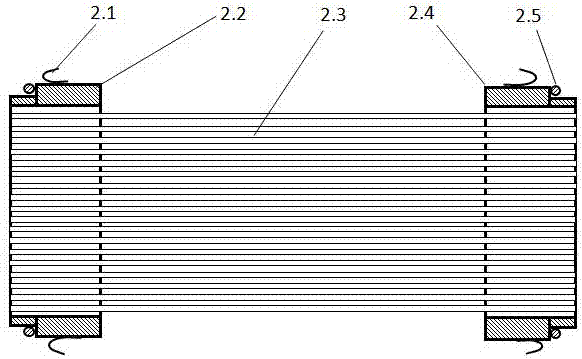

[0025] Example 1, the length of the membrane wire is 0.7 meters, the diameter is 3.5 mm, the quantity is 2000, the cross-sectional diameter of the head of the membrane group is 300 mm, and the buckle connection is made.

example 2

[0026] Example 2, the length of the membrane wire is 0.5 meters, the diameter is 1-2mm, the quantity is 500-2000 pieces, the cross-sectional diameter of the head of the membrane group is 50-300mm, and the buckle connection. Arrays are used in parallel.

example 3

[0028] Beneficial effect

[0029] The experimental results show that the air filter element made of polytetrafluoroethylene hollow fiber membrane has a dust holding capacity of 5-10 times that of ordinary filters under the condition of pure dust pollution, which greatly prolongs the battery life of the engine in the desert environment time. It can withstand high temperatures of -70 degrees ------100 degrees, the volume is reduced by 30%, and the pressure loss is reduced by 50%, which is of great significance for many special vehicles. Due to the greatly improved filtration accuracy, the cylinder wear can be effectively reduced. Due to the greatly improved dust holding capacity of the filter element, the maintenance cycle is greatly extended compared with ordinary vehicles. Since the filter material is washable and recyclable, the environmental protection benefits are also greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com