Hydraulic control system for automatic gearbox

A technology of hydraulic control system and automatic transmission, applied in transmission control, components with teeth, belts/chains/gears, etc., which can solve the problems that automatic transmissions cannot be entered, gears cannot be interlocked, and vehicles cannot be moved. , to improve the efficiency of the transmission, reduce the power consumption of the oil pump, and achieve the effect of compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

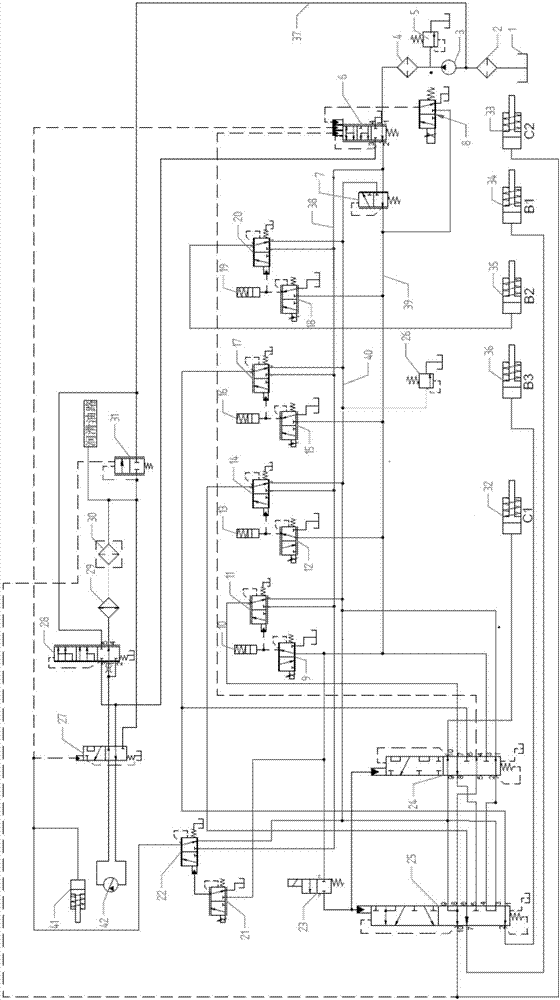

[0030] see figure 1 , The hydraulic control system of the automatic transmission of the present invention is composed of three parts of the oil circuit, which are respectively the oil supply oil circuit, the shift control oil circuit, the torque converter and the cooling lubricating oil circuit.

[0031] The oil supply route consists of an oil tank 1, a first filter 2, a second filter 4, an oil pump 3, an overflow valve 5, a system pressure regulating valve 6, a proportional solenoid valve 8 and a recirculation oil circuit 37. The first filter 2 is installed between the oil pump and the oil tank, which can remove large-sized pollutants in the oil tank, and the second filter 4 is installed behind the high-pressure oil outlet of the oil pump to ensure that the oil entering the shift control oil circuit Reach the cleanliness required by the hydraulic system. The oil thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com