Alternating current arc smelting furnace

An AC arc and melting furnace technology, which is applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve problems such as poor arc ignition performance, impact on the life of furnace material refractory materials, and low electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

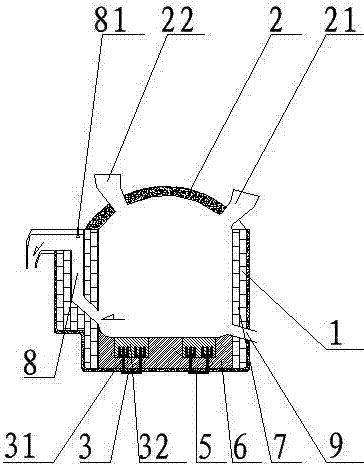

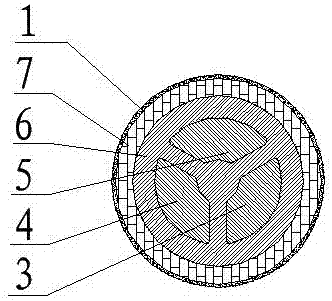

[0011] An AC arc melting furnace according to the present invention mainly consists of two parts: a furnace body (1) and a furnace cover (2). The furnace cover (2) is located on the top of the furnace body (1) and is provided with a raw material inlet (21) and The auxiliary material inlet (22); the furnace body (1) is a cylindrical structure with a three-phase AC electrode (3) at the bottom, and the three-phase AC electrode (3) is a circular ring surrounded by three fan-shaped structures, three-phase Each electrode of the three-phase AC electrode (3) is composed of a metal electrode (31) and a refractory electrode (32). The metal electrode (31) is made of multiple copper strips. The fork-shaped electrode made of rod is welded on the fan-shaped copper plate, the length of the fork-shaped electrode is 2 / 3 of the thickness of the furnace bottom, and the fan-shaped copper plate is partly exposed outside the furnace body (1); The refractory material (6) is layered and tamped to 1 / 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com