A method of fabricating an optical fiber collimator array

An optical fiber collimator and manufacturing method technology, applied in the field of optical communication, can solve the problems of short working distance, assembly process requirements, array lens process limitations, etc., and achieve accelerated curing rate, adjustable working distance, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

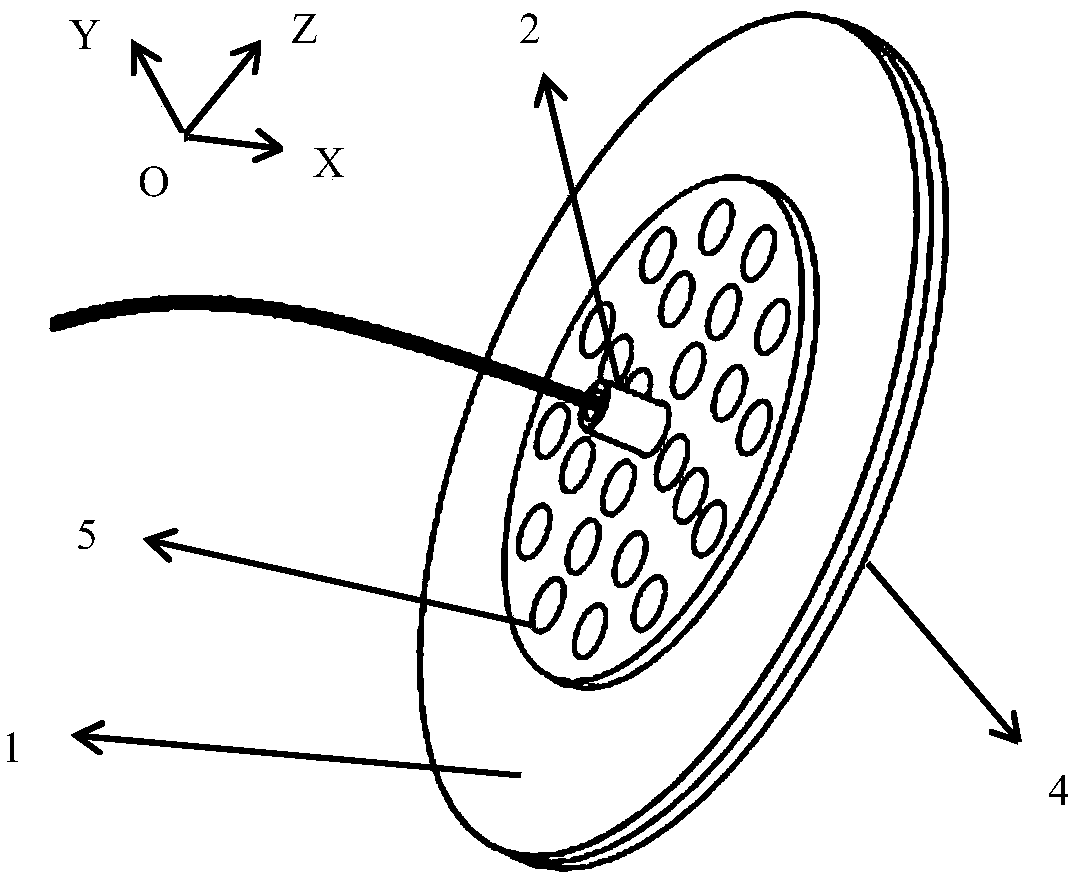

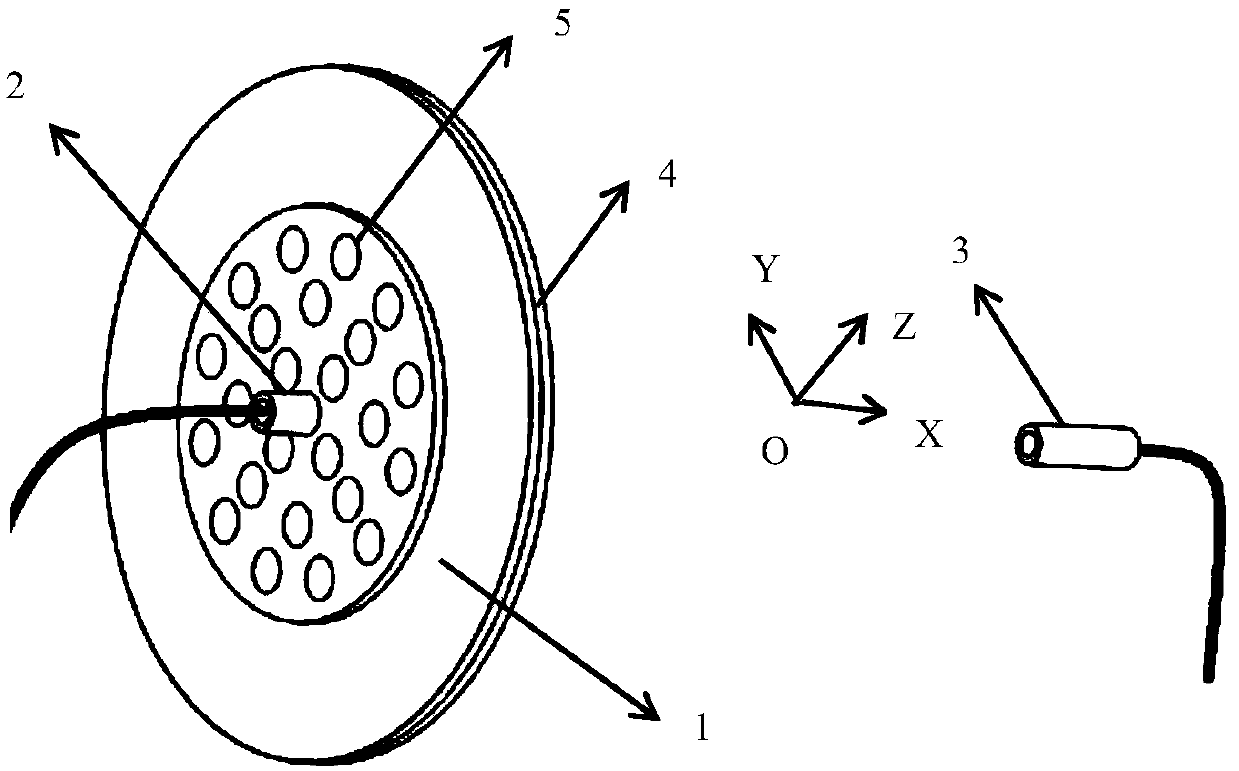

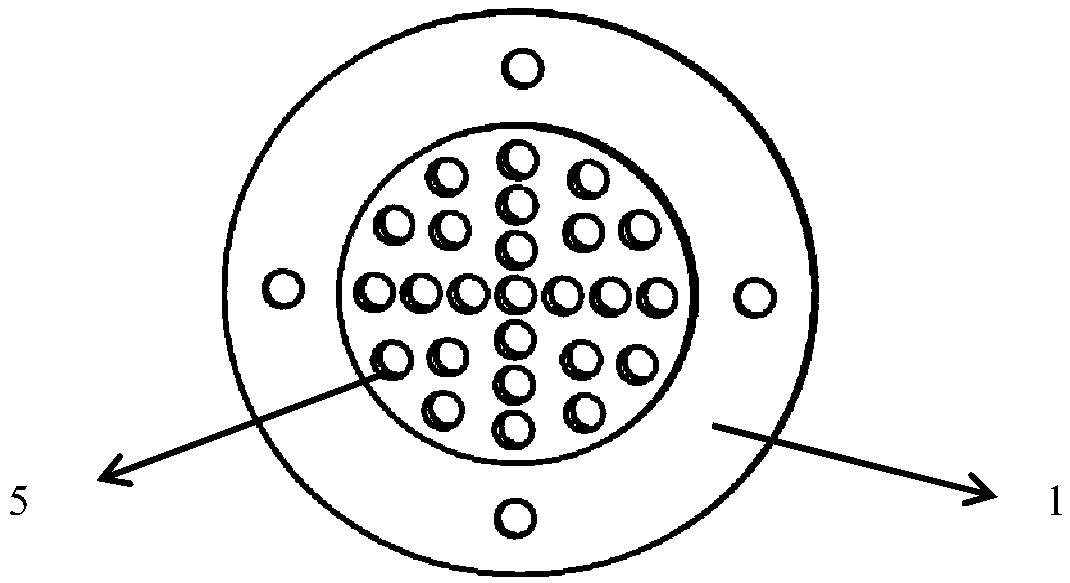

[0026] A method for manufacturing an optical fiber collimator array. The optical fiber collimator array includes a base 1 and an optical fiber collimator 2. The base 1 is provided with a number of mounting holes 5 corresponding to the number of optical fiber collimators.

[0027] The invention is described below by taking the 25-core fiber collimator shown in the accompanying drawings as a preferred embodiment.

[0028] Step 1, stick the heating device 4 on the surface of the base 1, and heat the base 1 to any temperature between 60°C and 150°C, preferably 60°C, 80°C, 120°C and 150°C in this embodiment , and keep heated throughout the production process.

[0029] Step 2, see figure 1 , observe through a microscope, adjust the coordinates of the fiber collimator 2 in the center mounting hole of the base through a fine-tuning device, install t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com