Scalable Array Fiber Output Lasers

A technology for expanding arrays and lasers, applied in the field of lasers, can solve the problems of small spot area, low safety and reliability, and low output power, and achieve the effects of high safety and reliability, improved safety, and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be further described below in conjunction with the accompanying drawings.

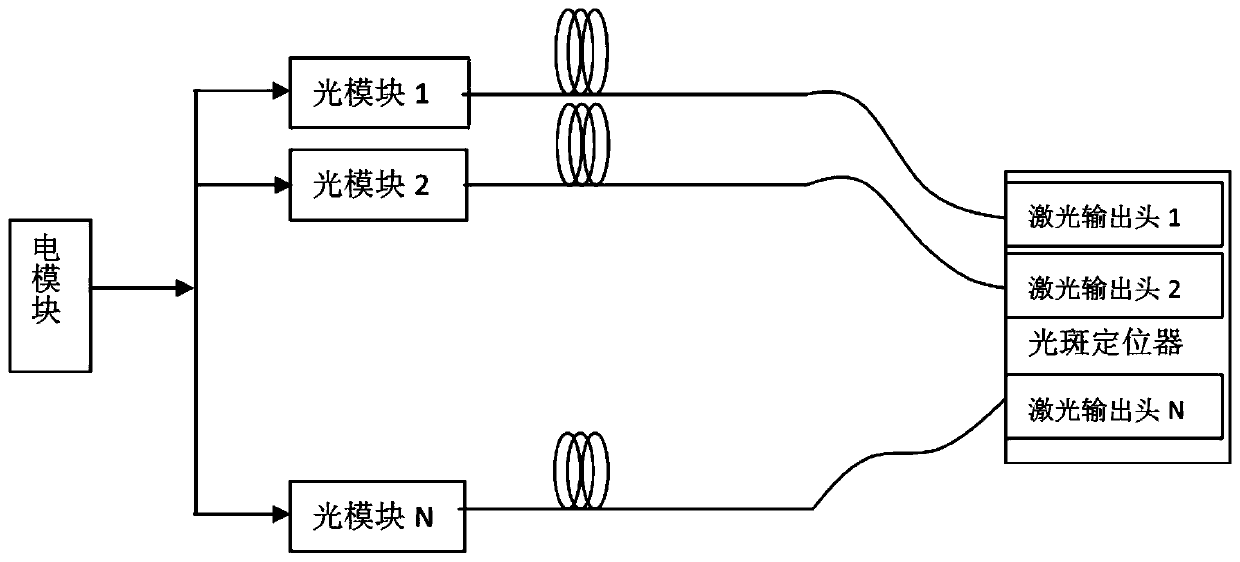

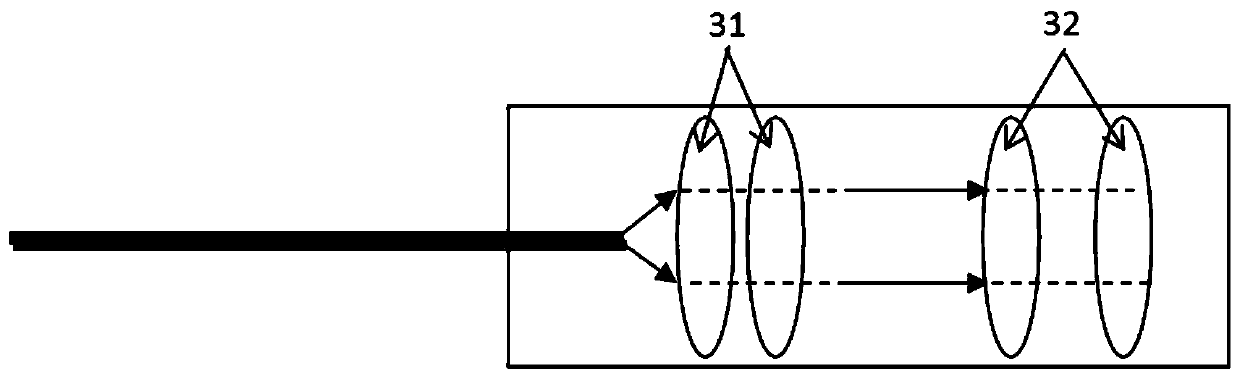

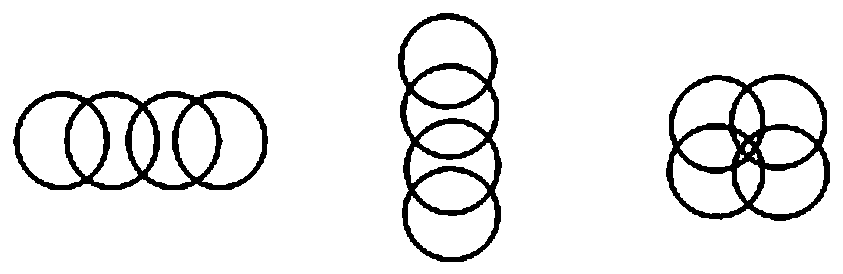

[0050] Such as figure 1 , The structure of the expandable array fiber output laser of the present invention includes: an electrical module, N optical module units, an output optical fiber, a laser output head and a spot positioner. The electrical module supplies power to and controls N optical module units at the same time, so that all or part of the optical modules can emit light at the same time. The output laser light of the optical module is transmitted to the corresponding laser output head through the optical fiber. The laser output head contains a collimating lens 31 system and a focusing The lens 32 system can focus the light beam into a spot of a certain shape. The laser output heads are all fixedly placed on the spot positioner, and the beam transmission direction is controlled by the spot positioner, and finally the following Figure 3a and Figure 3b The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com