Nano-brick array holographic sheet applied to holographic anti-counterfeiting and design method for nano-brick array holographic sheet

A holographic anti-counterfeiting and holographic sheet technology, applied in the field of nano-brick array holographic sheet and its design, can solve the problems of lack of large-scale batch copying, affecting visual effects, color stripes, etc., and achieve good phenomenon quality, visual comfort and high brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0051] In the embodiment of the present invention, the dominant wavelength λ=0.658 μm in the visible light band is selected as the working wavelength, and the diffraction distance z of the hologram is set to be 5 μm.

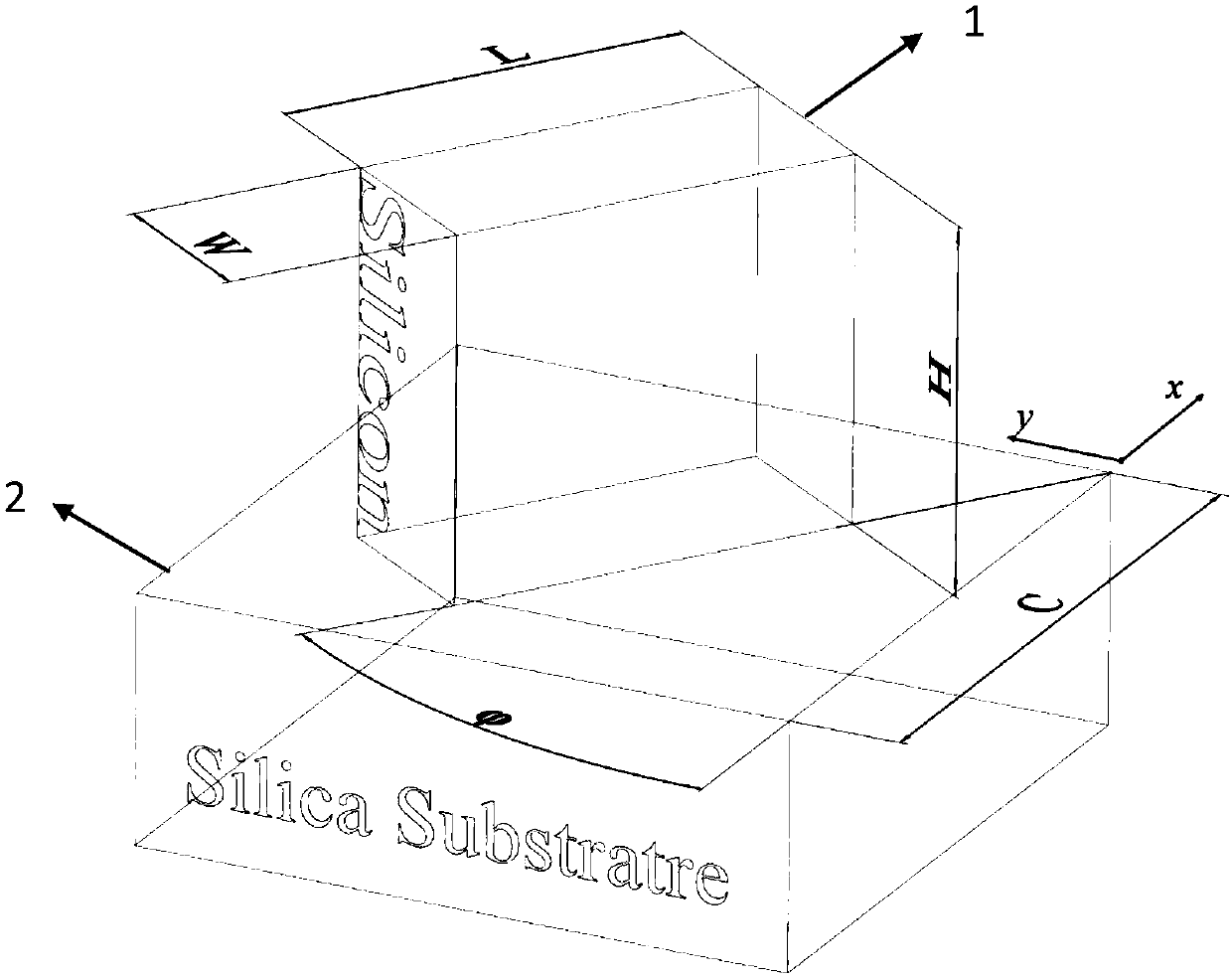

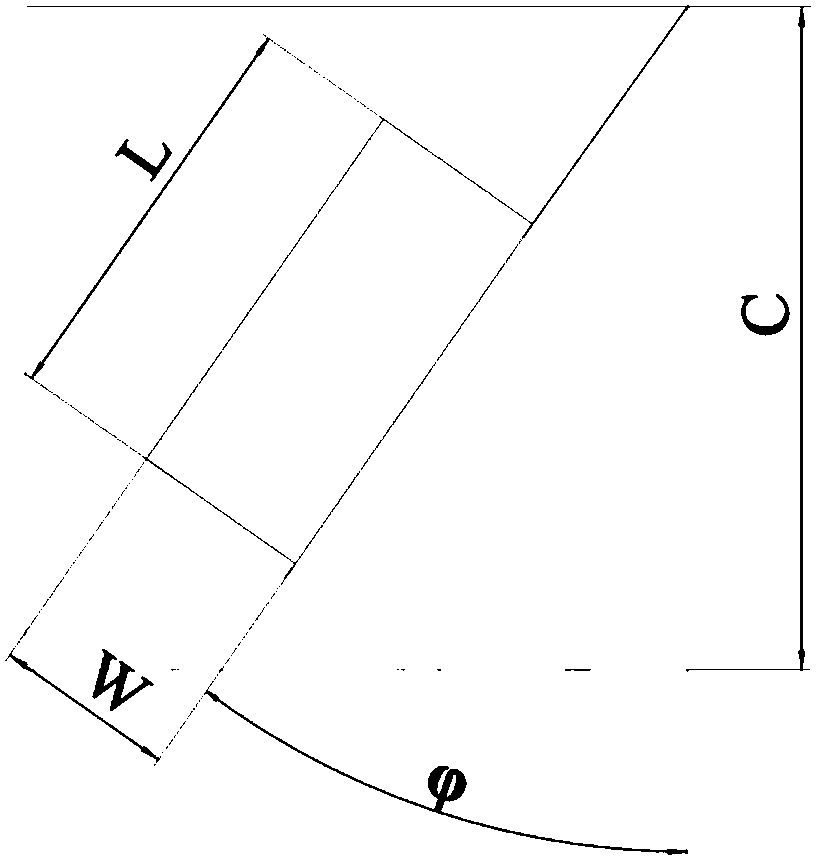

[0052] First, determine the basic structure of the nanobricks and substrate as well as the materials used, such as Figure 1~2 As shown, the nano-brick array holographic sheet includes 1-nano-bricks, made of amorphous silicon material; 2-substrate, made of fused silica material. W is the width of the nano-brick, H is the height of the nano-brick, C is the side length of a single unit structure, L is the length of the nano-brick, and φ is the orientation angle of the nano-brick.

[0053] The second step is to optimize the geometric parameters of the nano-brick array hologram, the geometric parameters include the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com