Incorporated device and method for controlling incorporated device

An assembly device and power control technology, applied in chemical instruments and methods, electrolysis components, fuel cells, etc., can solve problems such as electrode life reduction, electrolytic cell heating, peeling, etc., and achieve the effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

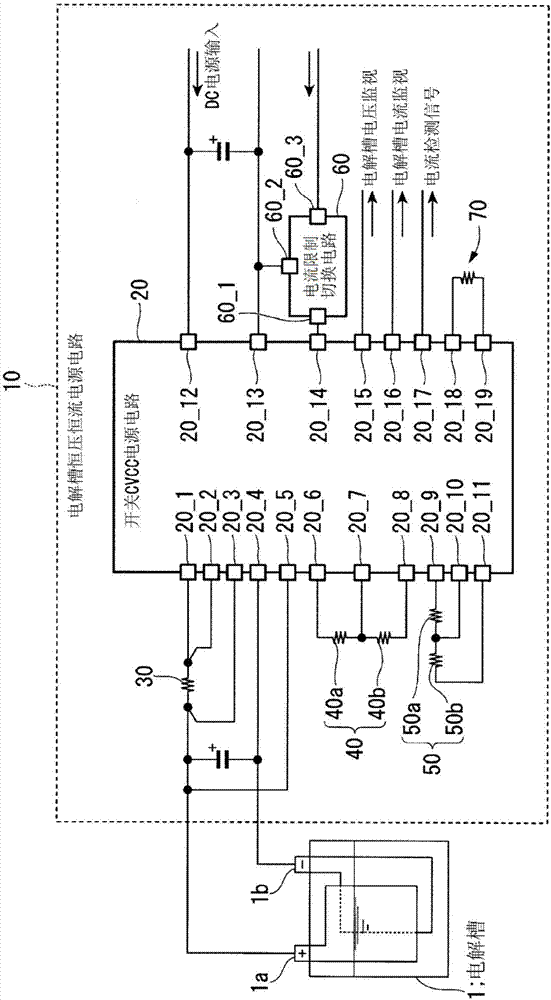

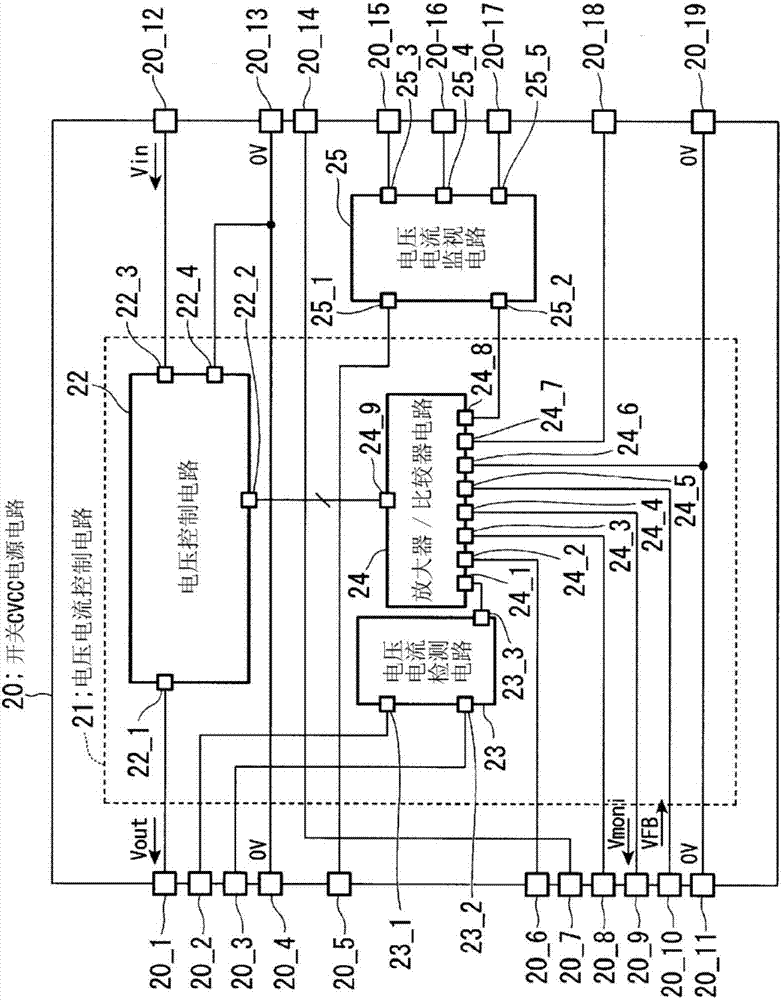

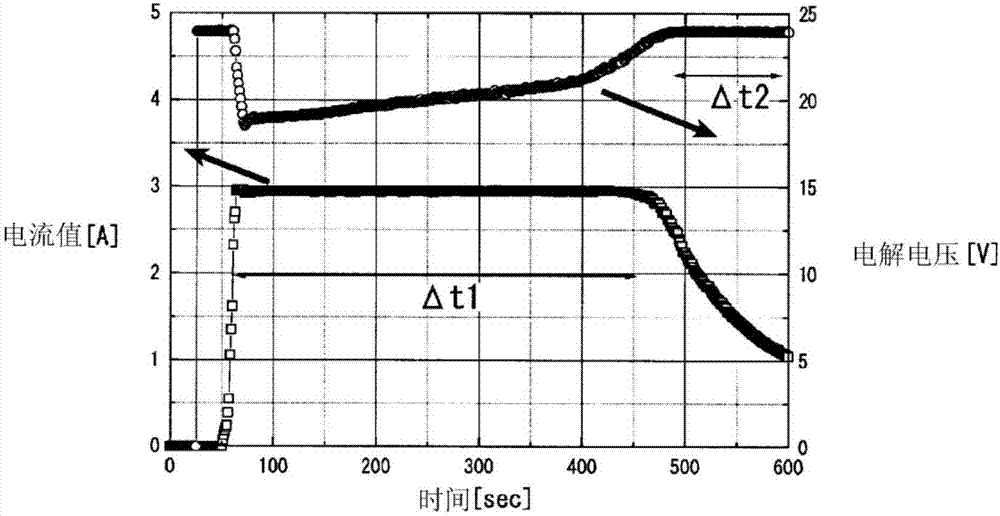

[0108] Below, refer to Figure 6 ~ Figure 14 An experimental example of throttling control using the electrolytic cell 1 , the electrolytic cell constant-voltage constant-current power supply circuit 10 , and a thermostat (assembly device 100 ) incorporating the electrolytic cell 1 and the electrolytic cell constant-voltage constant-current power supply circuit 10 will be described. Figure 6 ~ Figure 12 The time-lapse change of the electric current value at each rated temperature when the rated temperature is 30 degreeC - 50 degreeC is shown, respectively.

[0109] As the electrolytic tank 1, the electrolytic tank whose number of electrolytic cells was 6 was used. By supplying 9% hydrochloric acid to the electrolytic cell 1, the electrolytic voltage when an electrolytic current of 3 A was applied to the switching CVCC power supply circuit 20 was adjusted to 10V. Chlorine gas produced by electrolysis was injected into water at a flow rate of 20 L per hour.

[0110] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com