Refrigeration cycle device

A refrigeration cycle and refrigerant technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of longer construction time, higher construction costs, higher material costs, etc., to achieve compactness and shorten construction time , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

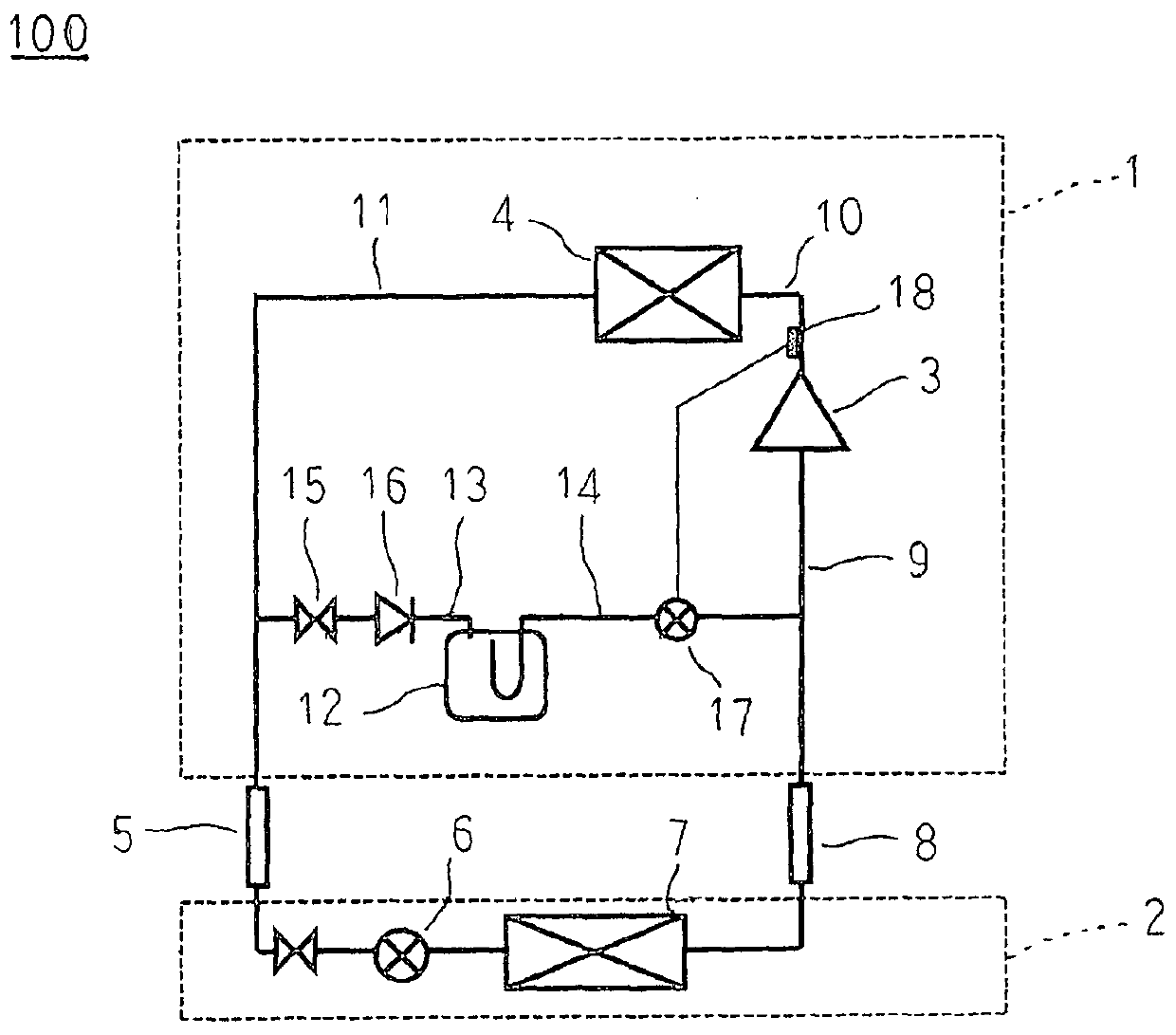

[0025] figure 1 It is a refrigerant circuit configuration diagram of the refrigeration cycle apparatus according to Embodiment 1 of the present invention.

[0026] exist figure 1 Among them, the refrigeration cycle device 100 is provided with: a heat source unit 1, the heat source unit 1 is installed outdoors; a cooling unit 2, the cooling unit 2 is installed in a cooling object, such as a store such as a convenience store or a supermarket; and a refrigerant storage tank 12, The refrigerant storage tank 12 stores refrigerant. Furthermore, the heat source unit 1 and the cooling unit 2 are connected via a liquid side bridging pipe 5 and a gas side bridging pipe 8 .

[0027] The heat source unit 1 includes a compressor 3 for compressing refrigerant and a condenser 4 as a heat source side heat exchanger. The suction side of the compressor 3 is connected to a gas side jumper pipe 8 via a gas side refrigerant pipe 9 . In addition, the discharge side of the compressor 3 is connec...

Embodiment approach 2

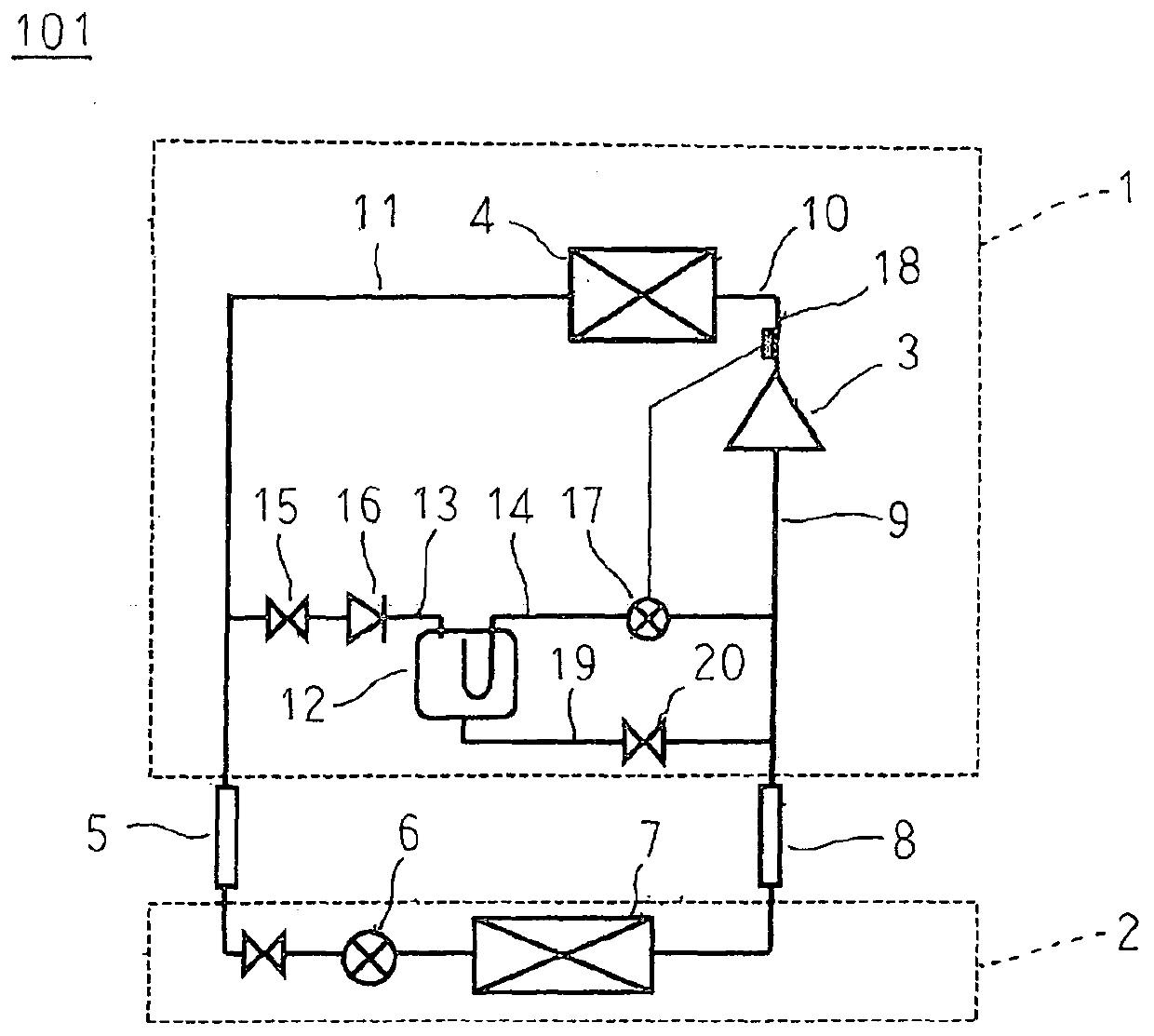

[0056] figure 2 It is a refrigerant circuit configuration diagram of a refrigeration cycle apparatus according to Embodiment 2 of the present invention.

[0057] exist figure 2 Among them, the refrigerant return pipe 19 is arranged to connect the lower part of the refrigerant storage tank 12 and the gas side refrigerant pipe 9 . An outlet-side solenoid valve 20 that is energized and opened is provided on the refrigerant return pipe 19 .

[0058] In addition, other configurations are configured in the same manner as in the first embodiment.

[0059] The refrigeration cycle device 101 according to Embodiment 2 operates in the same manner as the above-mentioned refrigeration cycle device 100 while the outlet side solenoid valve 20 is opened during normal operation. In addition, when the refrigeration cycle device 101 stops abnormally, the outlet side electromagnetic valve 20 is closed and operates in the same manner as the refrigeration cycle device 100 described above.

[...

Embodiment approach 3

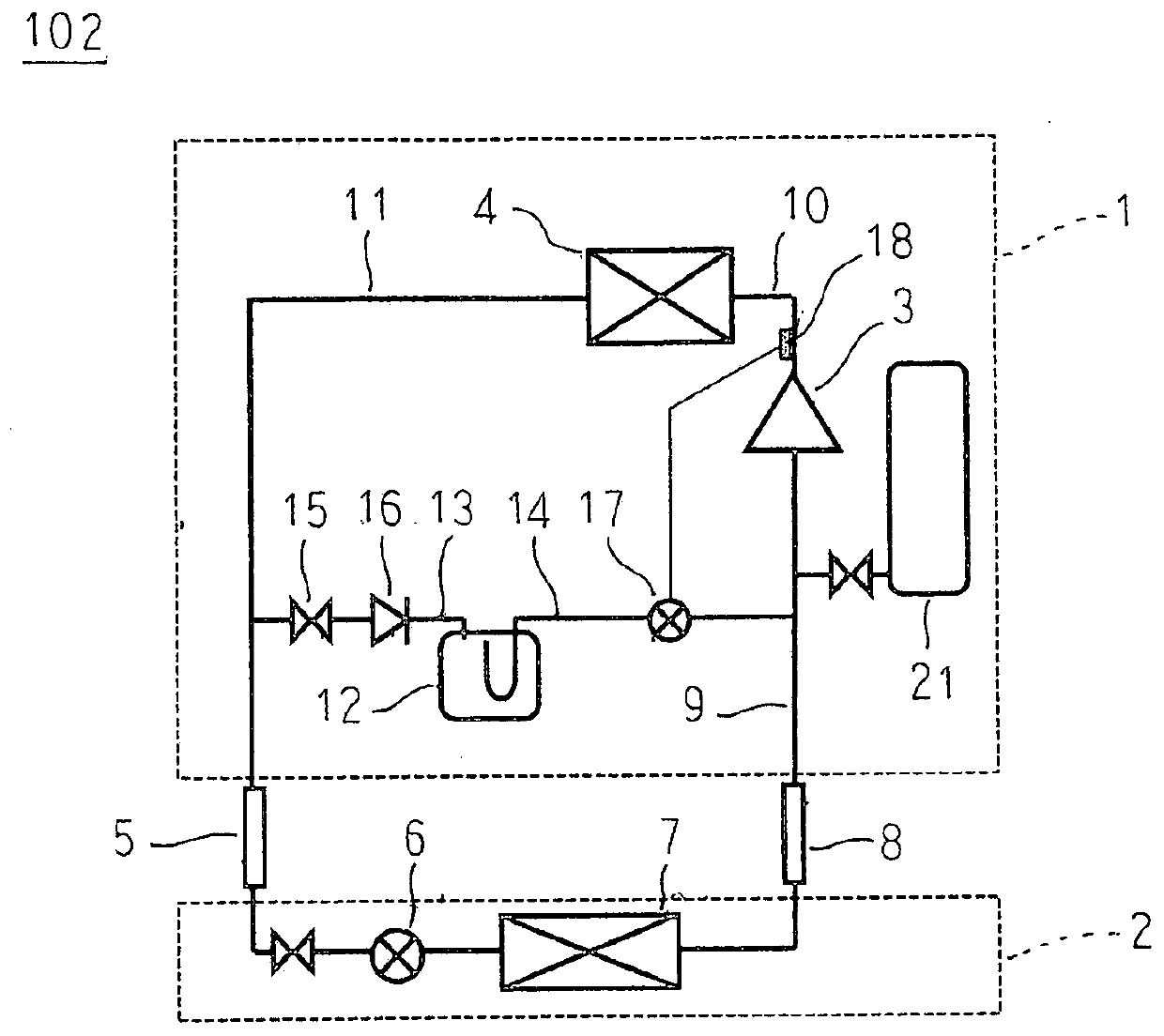

[0064] image 3 It is a refrigerant circuit configuration diagram of a refrigeration cycle apparatus according to Embodiment 3 of the present invention.

[0065] exist image 3 Among them, the expansion tank 21 is connected to the gas-side refrigerant piping 9 that is the suction side of the compressor 3 .

[0066] In addition, other configurations are configured in the same manner as in the first embodiment.

[0067] In the refrigeration cycle apparatus 102 according to Embodiment 3, the expansion tank 21 is connected to the gas-side refrigerant pipe 9 , so that the internal volume of the main refrigerant circuit can be enlarged, and pressure rise in the main refrigerant circuit can be prevented. If the expansion tank 21 is installed separately, a large tank volume is required, and there is a possibility that the installation space and the cost are not practical. In Embodiment 3, since the expansion tank 21 and the refrigerant storage tank 12 are used together, the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com