Periphery drive sludge scraping and sucking machine

A technology of peripheral transmission and dredger suction, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank, and can solve the problems of increasing the occupied area, high energy consumption in operation, and mud content in the mixture. Less problems, to achieve the effect of saving floor space, good mud discharge effect, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

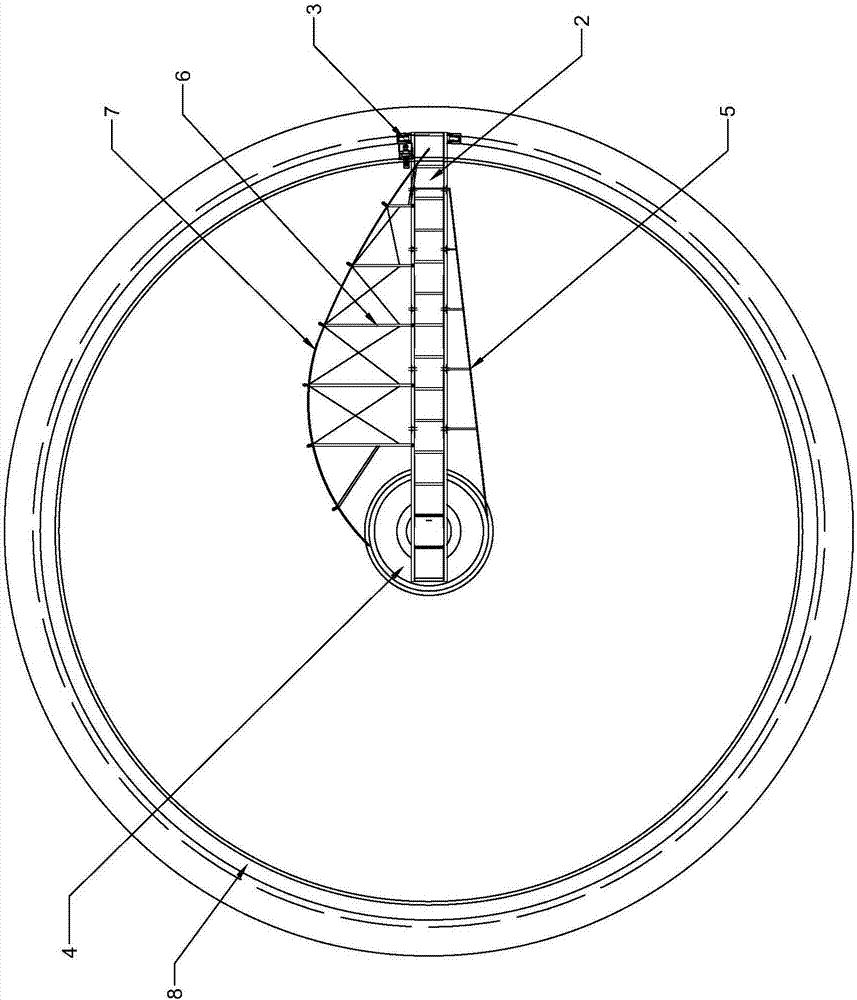

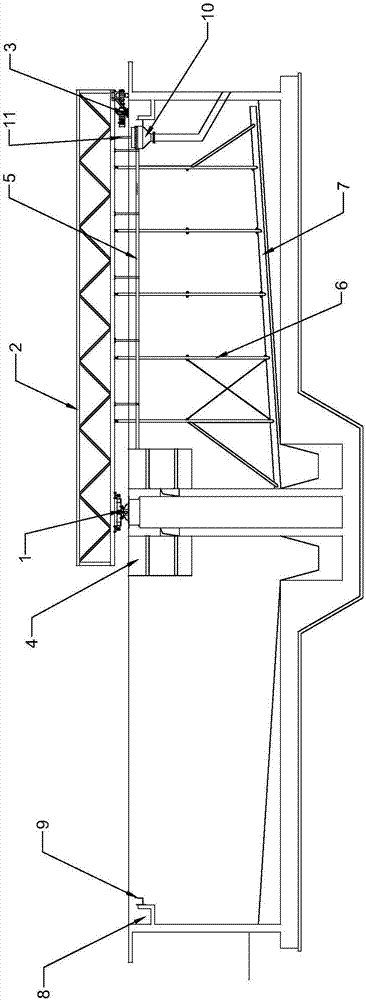

[0013] Such as figure 1 figure 2 As shown, the peripheral transmission scraper and suction machine consists of a slewing support device 1 arranged on the top of the central column of the circular pool body and a working bridge 2 fixed on the slewing support device 1 at one end. The other end of the working bridge 2 is provided with a The walking device 3 on the edge of the pool body, the top of the circular pool center column under the slewing support device 1 is provided with a plurality of steady flow cylinders 4, the periphery of the bottom of the circular pool body center column is a sludge sedimentation annular groove, and the working bridge 2 A horizontal slag scraper 5 is fixed at the bottom, and an arc-shaped scraper 7 is installed under the working bridge 2 through the scraper arm 6. The arc-shaped scraper 7 is close to the bottom of the pool body, and the outer edge of the pool is set on the inner wall. There is a ring-shaped overflow weir plate 8, and a ring of sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com