Cutting machine

A technology of cutting machine and cutting mechanism, which is applied in the direction of metal processing, etc., can solve the problems that the cutting depth cannot be effectively controlled, affects the cutting precision of the cutting machine, and the vibration of the cutting knife is large, so as to reduce the dust flying field, lower the temperature and improve the cutting precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

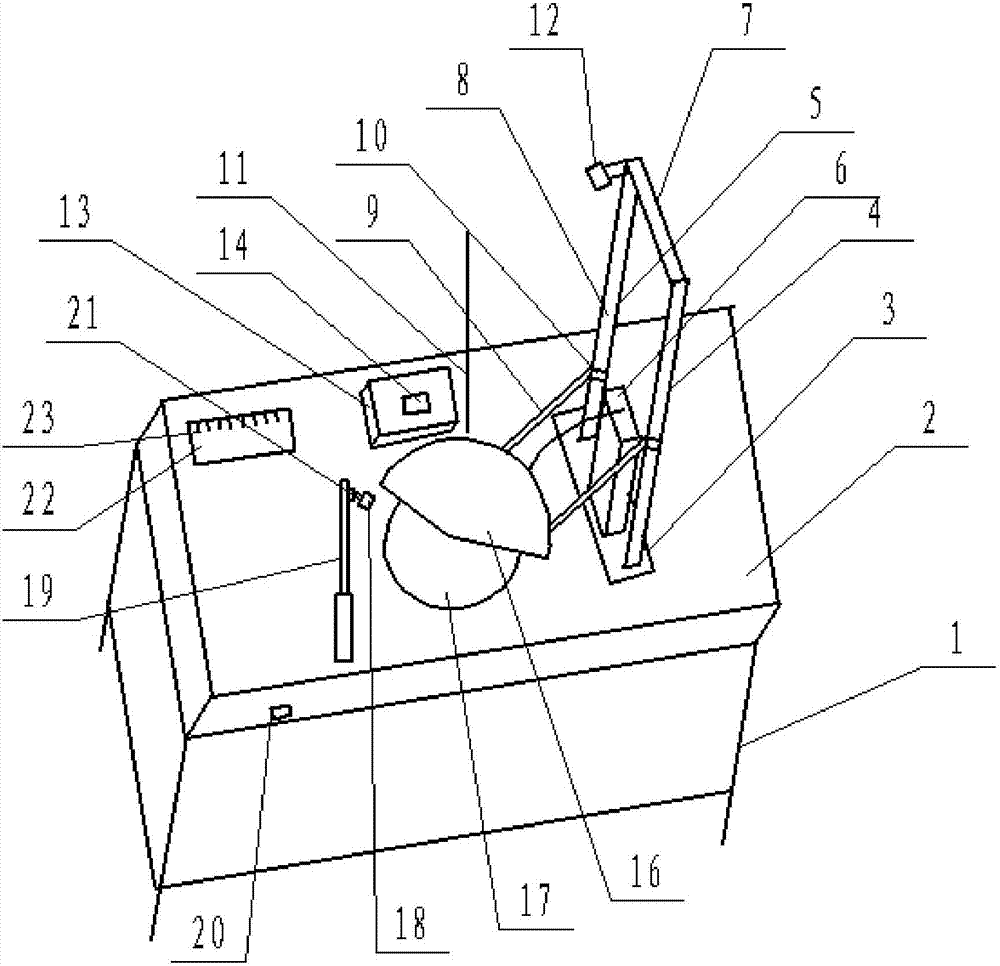

[0032] Such as Figure 1-Figure 2 , a cutting machine in this embodiment includes a frame 1, a workbench 2 is provided on the frame 1, a cutting mechanism and an automatic lifting mechanism are arranged on the workbench 2, and the cutting mechanism is located on the workbench 2, the automatic lifting mechanism is connected with the cutting mechanism through a connecting rod 9.

[0033] The automatic lifting mechanism includes a base 3, a first support rod 4 and a second support rod 5 arranged on the base 3, and is arranged between the first support rod 4 and the second support rod 5 and is located on the base 3 The upper lifting cylinder 6 and the limit rod 7 arranged on the ends of the first support rod 4 and the second support rod 5 . Both the first support rod 4 and the second support rod 5 are equipped with guide rails 8 , and the two connecting rods 9 connecting the automatic lifting mechanism and the cutting mechanism are provided with slide blocks 10 matched with the g...

Embodiment 2

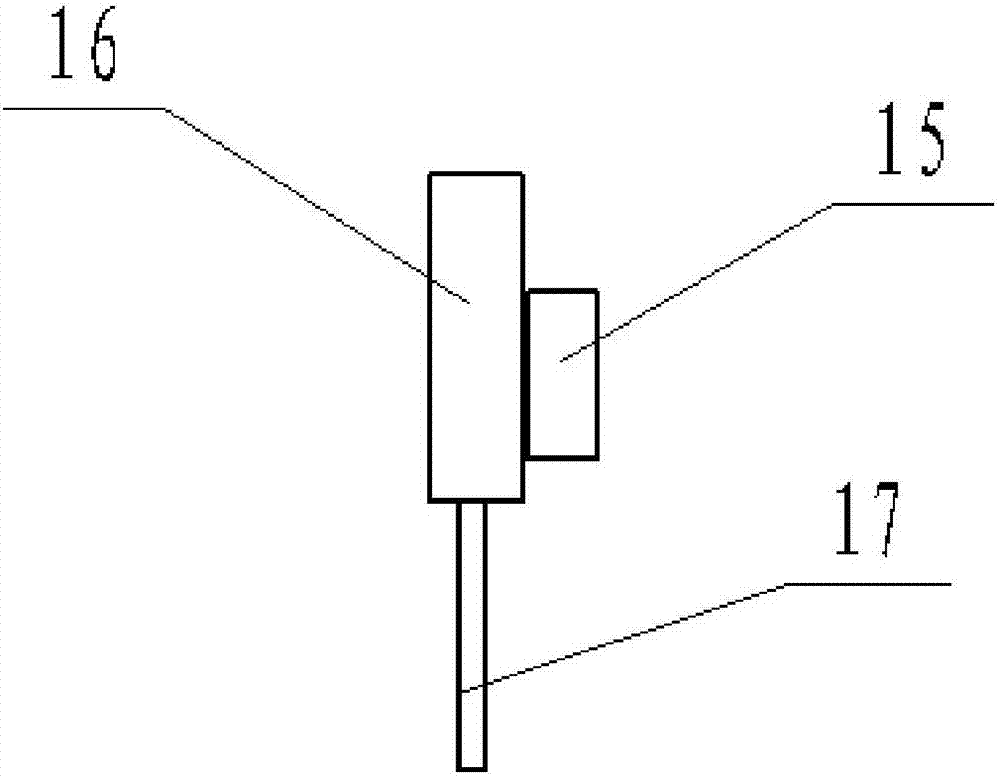

[0045] This embodiment is the same as embodiment 1 except that the raw material ratio and preparation method of the shock-absorbing material embedded in the cutter installation body 16 are different from those of embodiment 1.

[0046] The damping material of the present embodiment includes the following components by weight: 60 parts of bentonite, 40 parts of nitrile rubber, 20 parts of calcium carbonate, 15 parts of glass fiber, 15 parts of paraffin oil, 10 parts of alkyldiethanolamide, terpene 10 parts of resin, 8 parts of polyvinyl acetate, 8 parts of polyethylene terephthalate, 8 parts of tea saponin, 8 parts of xanthan gum and 5 parts of triethanolamine oleate.

[0047] Further, the preparation method of the shock absorbing material includes the following steps:

[0048] (1) Take the above-mentioned raw materials by weight;

[0049] (2) Put bentonite, polyethylene terephthalate and glass fiber bonded mixture, nitrile rubber, paraffin oil, polyvinyl acetate, terpene resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com