Improved structure of upper strip section of automobile door frame and manufacturing method of improved structure

A manufacturing method and technology for door frames, which are applied in the directions of doors, vehicle parts, transportation and packaging, etc., can solve the problems that the welding connection strength cannot be guaranteed, the area of the support pocket 5 becomes smaller, and the support pocket 5 leaks, etc., so as to improve the overall production efficiency, The effect of reducing weight and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

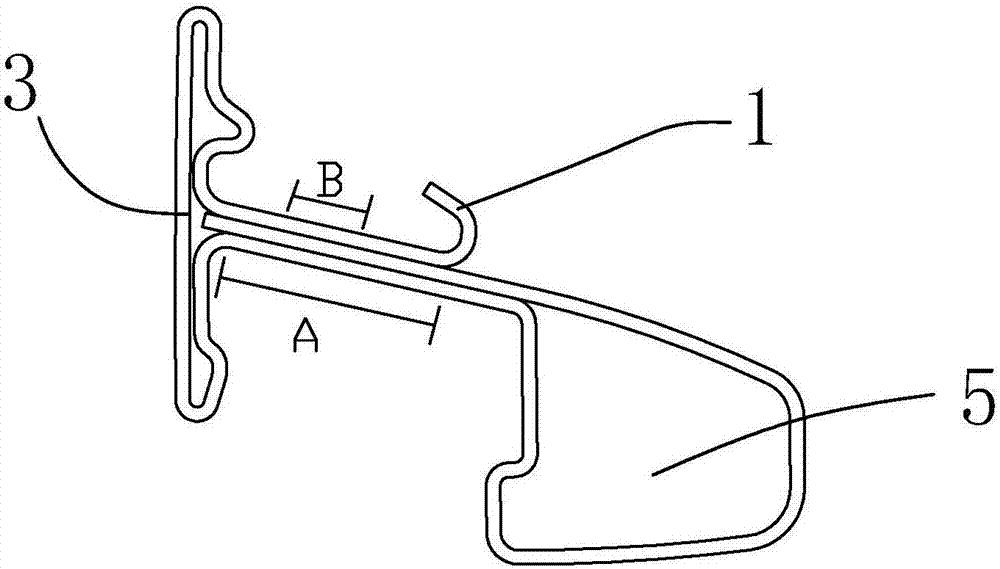

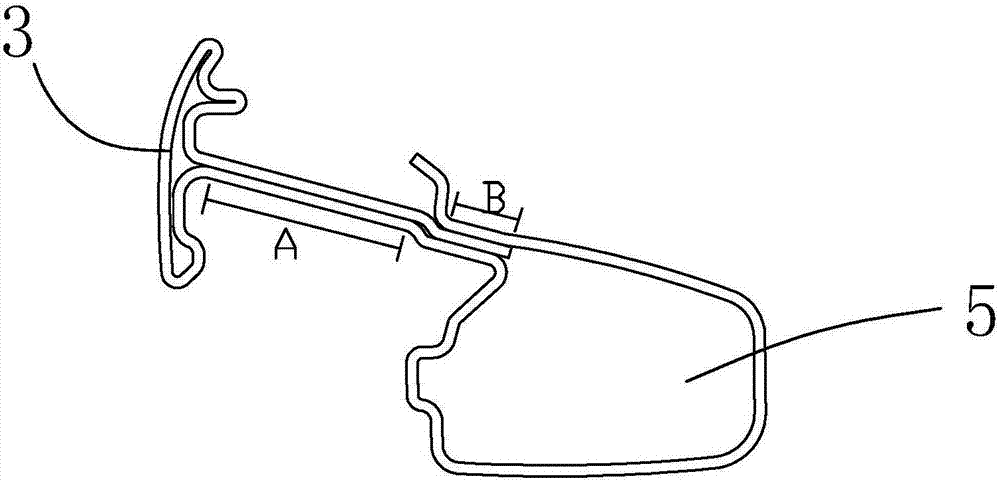

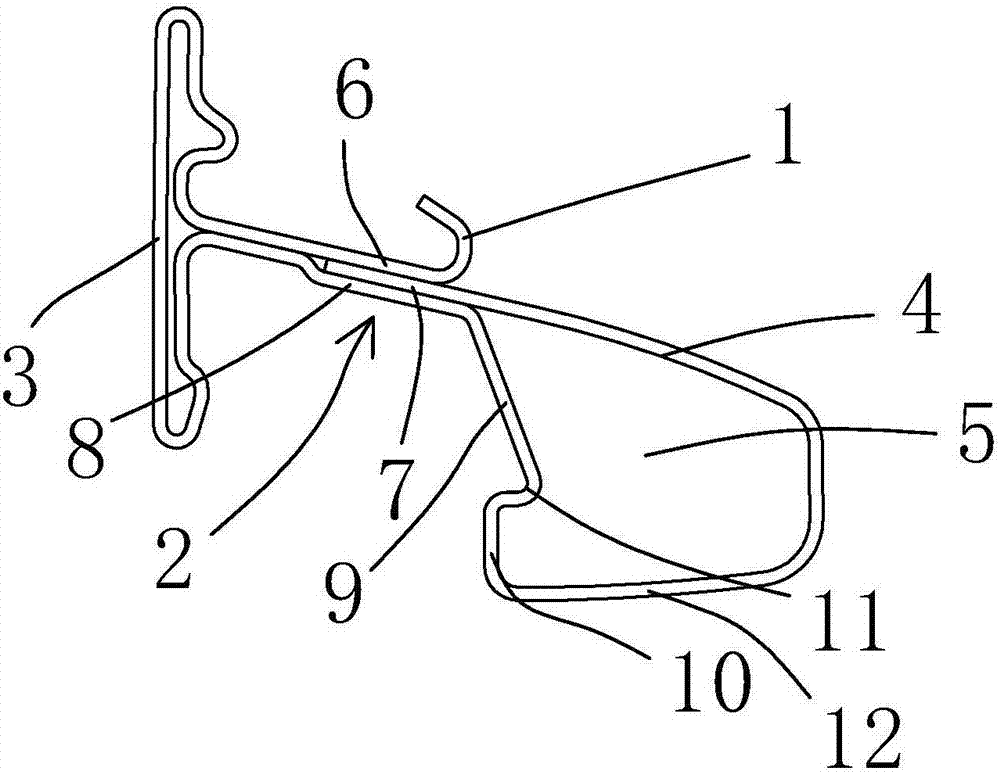

[0041] In the figure, the hook part 1; the overlap part 2; the outer end part 3; the cylindrical part 4; the support pocket 5; the hook extension part 6; the cylindrical starting end part 7; side 9; arc segment 10; V-shaped gap 11; bottom 12 of the cylindrical part.

[0042] like image 3 As shown, the improved structure of the upper section of the automobile door frame is continuously rolled and formed by one plate, including the hook part 1, the overlapping part 2, the outer end part 3 and the cylindrical part 4, and the hook part 1 is used as the end end of the roll forming And it is used to fix the door sealing strip. The hook part 1 is the first end side of the rolling section, and the overlapping part 2 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com