Preparation method of aluminum alloy wheel hub

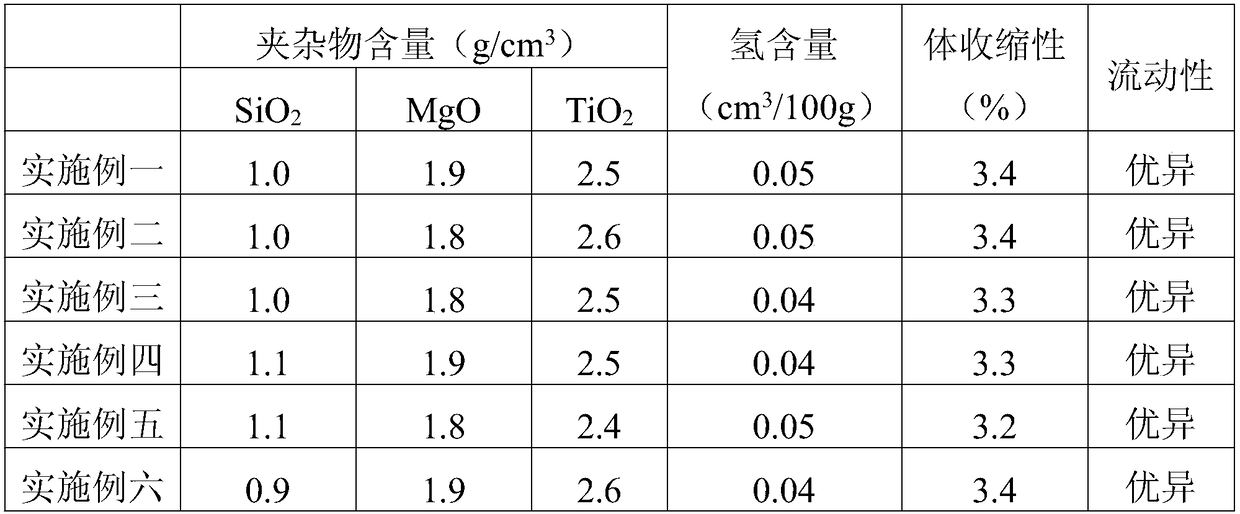

A technology of aluminum alloy wheel hub and aluminum ingot, applied in the field of metal materials, can solve the problems of increasing production cost, low qualification rate of aluminum alloy wheel hub, affecting the quality of aluminum alloy wheel hub, etc., so as to prolong the service life, improve fluidity and solidification shrinkage. properties, the effect of reducing the hydrogen content and the content of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing an aluminum alloy wheel hub, comprising:

[0019] Step 1. The aluminum ingot is smelted once to form an aluminum liquid. The temperature of the first smelting is 800-850° C., and the time of the first smelting is 20-30 minutes. The aluminum ingot includes the following components in parts by mass: Si 8-9 0.2-0.4 parts of Mg, 0.02-0.04 parts of Ti, 0.03-0.05 parts of Fe, 0.01-0.02 parts of Cu, 0.01-0.02 parts of Zn, and the rest are Al;

[0020] Step 2, adding a slag remover to the primary aluminum liquid, the slag remover includes sodium chloride, potassium chloride and sodium carbonate, wherein the mass ratio of sodium chloride, potassium chloride and sodium carbonate is 1:0.2- 0.4:0.2-0.4, the mass ratio of the slag-removing agent to the aluminum ingot is 0.3-0.5:1000 parts, followed by secondary smelting, the secondary smelting temperature is 600-650°C, and the secondary smelting time is 3- 5h, then let stand to discharg...

Embodiment 1

[0030] Step 1. Melt 1000 kg of aluminum ingot once to form molten aluminum. The temperature of the first smelting is 800° C. and the time of the first smelting is 20 minutes. The aluminum ingot includes the following components in parts by mass: Si 8-9 parts, Mg 0.2-0.4 parts, Ti 0.02-0.04 parts, Fe 0.03-0.05 parts, Cu 0.01-0.02 parts, Zn 0.01-0.02 parts, the rest is Al;

[0031] Step 2, adding a slag remover to the primary aluminum liquid, the slag remover includes sodium chloride, potassium chloride and sodium carbonate, wherein the mass ratio of sodium chloride, potassium chloride and sodium carbonate is 1:0.2: 0.2, the mass ratio of the slag-removing agent to the aluminum ingot is 0.3:1000 parts, followed by secondary smelting, the secondary smelting temperature is 600°C, the secondary smelting time is 3h, and then the slag is discharged by standing still;

[0032] Step 3, adding a refining agent to the secondary aluminum liquid after deslagging for refining, the refining ...

Embodiment 2

[0035] Step 1. Melt 1000 kg of aluminum ingot once to form molten aluminum. The temperature of the first smelting is 850° C. and the time of the first smelting is 30 minutes. The aluminum ingot includes the following components in parts by mass: Si 8-9 parts, Mg 0.2-0.4 parts, Ti 0.02-0.04 parts, Fe 0.03-0.05 parts, Cu 0.01-0.02 parts, Zn 0.01-0.02 parts, the rest is Al;

[0036] Step 2, adding slag-removing agent to primary aluminum liquid, described slag-removing agent comprises sodium chloride, potassium chloride and sodium carbonate, wherein, the mass ratio of sodium chloride, potassium chloride and sodium carbonate is 1:0.4: 0.4, the mass ratio of the slag-removing agent to the aluminum ingot is 0.5:1000 parts, followed by secondary smelting, the secondary smelting temperature is 650°C, the secondary smelting time is 5h, and then the slagging is left standing;

[0037] Step 3: adding a refining agent to the slagging secondary aluminum liquid for refining, the refining age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com