T-shaped resin concrete drainage ditch and preparation method thereof

A resin concrete and drainage ditch technology, used in drainage structures, waterway systems, water supply devices, etc., can solve the problems of not being able to achieve the ideal design effect of linear drainage ditch, reducing service life, and rough appearance of brickwork, and achieving good climate adaptation. performance, optimized processing performance, easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

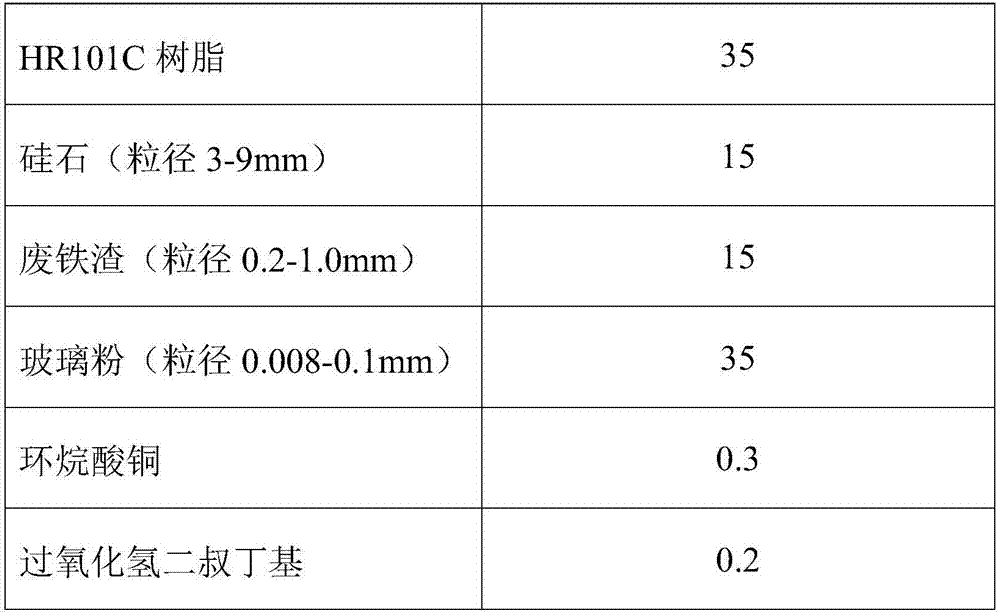

Embodiment 1

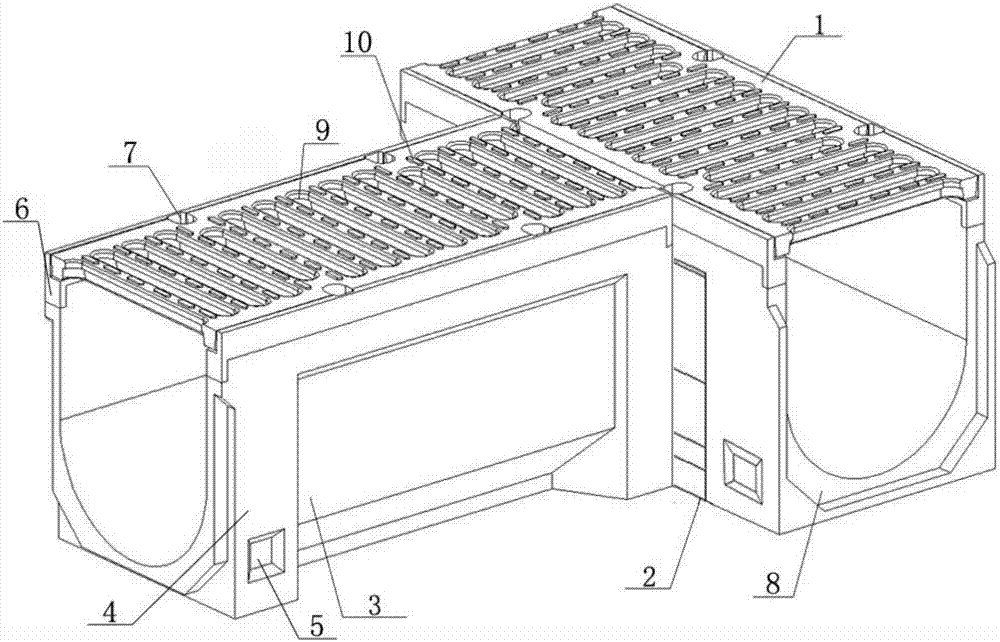

[0032] according to figure 1 A T-shaped resin concrete drainage ditch shown includes a cast iron cover plate 1 and a tank body, the tank body includes a horizontal tank body 2 and a vertical tank body 3, and the side of the horizontal tank body 2 is perpendicular to the end of the vertical tank body 3 The connection forms a T shape, and the tank body is integrally formed. The two ends of the side walls of the horizontal tank body 2 and the vertical tank body 3 are provided with reinforcing ribs 4, and the bottom of the reinforcing rib 4 is provided with concave holes 5. The cast iron cover plate 1 has two Blocks are respectively covered on the top of the horizontal trough body 2 and the vertical trough body 3.

[0033] The top edge of the tank body is provided with a cast iron arm bar 6, and the cast iron arm bar 6 is poured into the tank body, and the cross section of the cast iron arm bar 6 is L-shaped, so that the cast iron cover plate 1 is embedded therein. The edge of th...

Embodiment 2

[0047] according to figure 1A T-shaped resin concrete drainage ditch shown includes a cast iron cover plate 1 and a tank body, the tank body includes a horizontal tank body 2 and a vertical tank body 3, and the side of the horizontal tank body 2 is perpendicular to the end of the vertical tank body 3 The connection forms a T shape, and the tank body is integrally formed. The two ends of the side walls of the horizontal tank body 2 and the vertical tank body 3 are provided with reinforcing ribs 4, and the bottom of the reinforcing rib 4 is provided with concave holes 5. The cast iron cover plate 1 has two Blocks are respectively covered on the top of the horizontal trough body 2 and the vertical trough body 3.

[0048] The top edge of the tank body is provided with a cast iron arm bar 6, and the cast iron arm bar 6 is poured into the tank body, and the cross section of the cast iron arm bar 6 is L-shaped, so that the cast iron cover plate 1 is embedded therein. The edge of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com