Fractal dimension representation method for expansion trend of corrosion fatigue crack of gas pipeline

A fractal dimension and crack propagation technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of uncertainty, time-consuming and labor-intensive, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

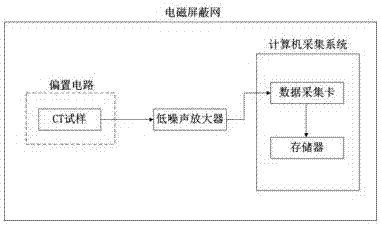

[0064] A fractal dimension characterization method for corrosion fatigue crack growth tendency of gas pipeline, comprising the following steps:

[0065] 1. Cut the pipe and make a CT sample, followed by surface cleaning and drying

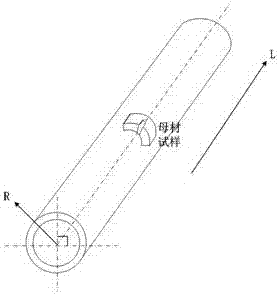

[0066] 1) Cut the pipe: press figure 1 As shown, the arc-shaped pipe was cut. The test material was taken from a certain pipe in Puguang Gas Field. The design pressure was 11MPa and the wall thickness was 17.5mm. That is, the circumferential direction; R indicates that the crack expands along the wall thickness. Since the pipe wall is very thin, it is impossible to cut the sample according to the CR orientation, so the sample can only be cut from the pipe according to the CL orientation. L is the direction of crack propagation, according to CL Orientation intercepted 3 samples of base metal;

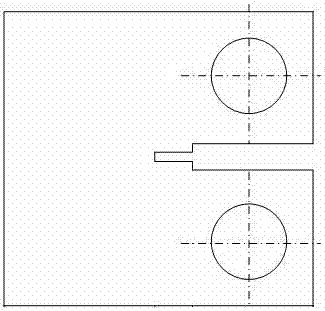

[0067] 2) Preparation of CT samples: CT samples were made according to GB / T 6398-2000 standard. After the above-mentioned arc-shaped samples were removed, ...

Embodiment 2

[0089] A fractal dimension characterization method for corrosion fatigue crack growth tendency of gas pipelines, the main steps of which are as follows:

[0090] Step 1, cut the pipe and make a CT sample, followed by surface cleaning and drying;

[0091] (1) Cut and prepare CT sample: press figure 1 Cut the curved tube as shown, and then make the curved tube into a CT sample (such as figure 2 shown);

[0092] (2) Prefabricated fatigue cracks: the precrack load ratio is 0.1, the maximum load is 10kN, and the length of the prefabricated fatigue cracks is about 1.5-2mm;

[0093] (3) Cleaning: firstly carry out rust removal on the surface of the sample, and the formula of the rust removal solution is as follows:

[0094] formula weight percentage Hydrochloric acid (mass concentration 15%) 55% Hexamethylenetetramine 10% water 35%

[0095] Soak the sample in the derusting solution to ensure that the surface of the CT sample is fully exposed to ...

Embodiment 3

[0113] A fractal dimension characterization method for corrosion fatigue crack growth tendency of gas pipelines, the main steps of which are as follows:

[0114] Step 1, cut the pipe and make a CT sample, followed by surface cleaning and drying.

[0115] 1) Cut and prepare CT sample: press figure 1 Cut the curved tube as shown, and then make the curved tube into a CT sample (such as figure 2 shown).

[0116] 2) Pre-fabricated fatigue cracks: the pre-crack load ratio is 0.1, and the maximum load is 10kN. The length of the prefabricated fatigue crack is about 1.5-2mm.

[0117] 3) Cleaning: firstly carry out rust removal on the surface of the sample, the formula of the rust removal solution is as follows:

[0118] formula weight percentage Hydrochloric acid (mass concentration 15%) 55% Hexamethylenetetramine 10% water 35%

[0119] Soak the sample in the derusting solution to ensure that the surface of the CT sample is fully exposed to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com