Micro nano motor based on shearing piezoelectric stacks

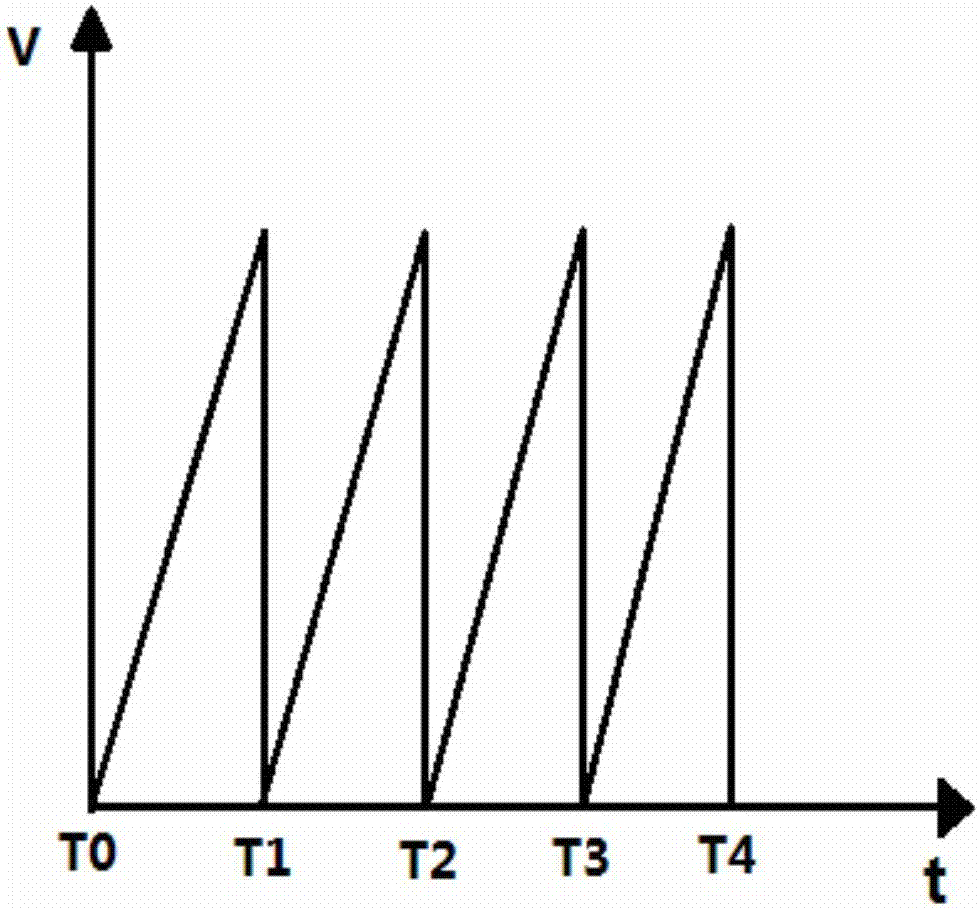

A piezoelectric stack and micro technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of single installation direction, weak anti-interference ability, and external Vibration sensitivity and other problems, to achieve the effect of good rigidity and stepping accuracy, less voltage drive signal, and strong structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail now in conjunction with accompanying drawing.

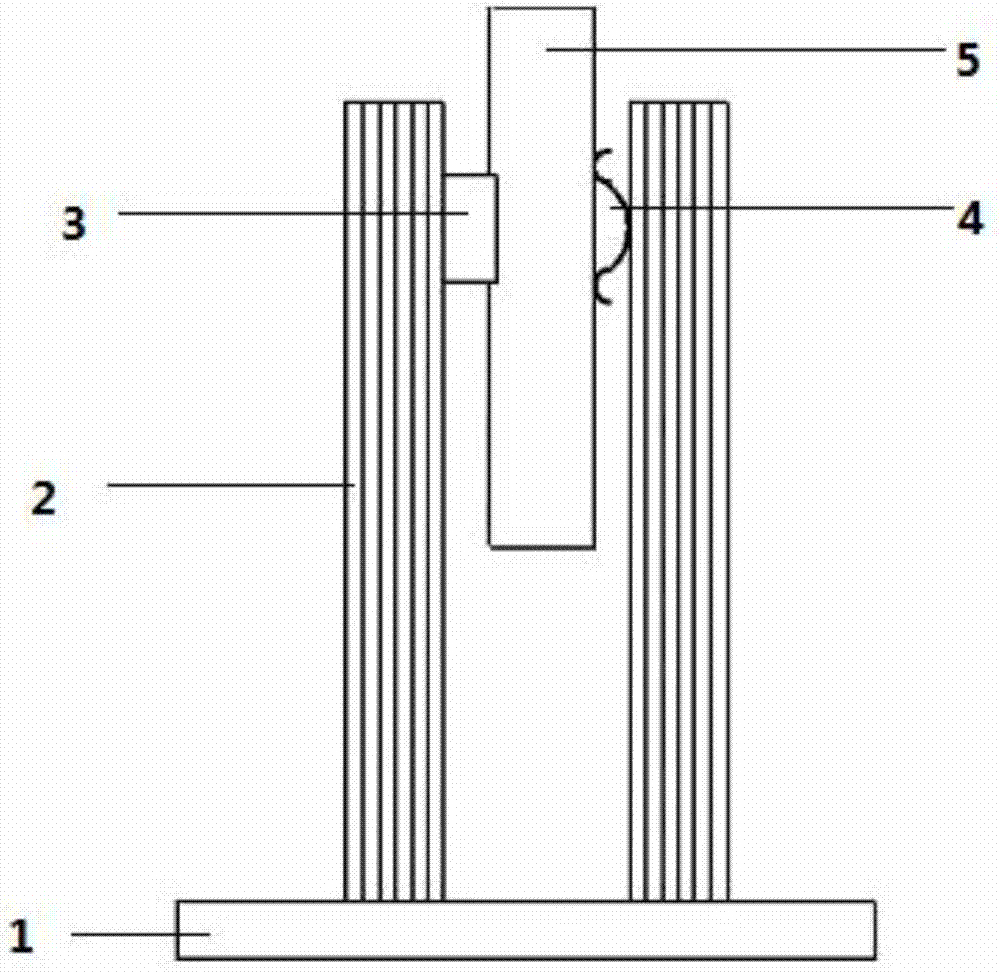

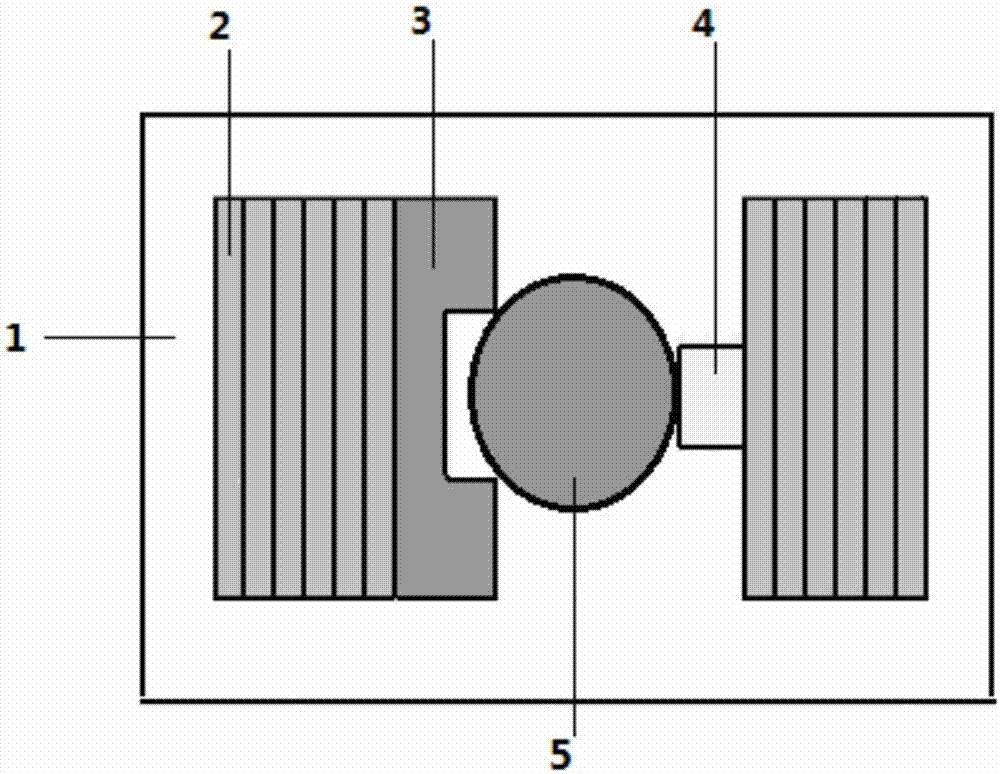

[0025] Based on various drawbacks of the motors in the prior art, the present invention makes corresponding improvements to the existing motor structure. First, the cylindrical insulating guide rail is replaced with a rectangular parallelepiped guide groove, because the design of this guide groove fits better with the shear piezoelectric stack, which can improve the structural rigidity and greatly reduce the difficulty of assembly. Secondly, a groove with a width slightly smaller than the diameter of the slide bar is vertically provided in the middle of the free end of the cuboid guide groove, and the two edges of the groove support the slide bar to replace the four silicon nitride balls in the previous structure, so that It not only improves the precision of the structure, but also reduces the frictional force between the force transmission block and the slide bar.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com