Integration processing equipment for motorbike chain wheel

An integrated processing and motorcycle technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low economic benefits, high labor intensity of workers, low production efficiency, etc., and achieve the liberation of labor intensity, quality assurance, Improve the slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described below in conjunction with accompanying drawing.

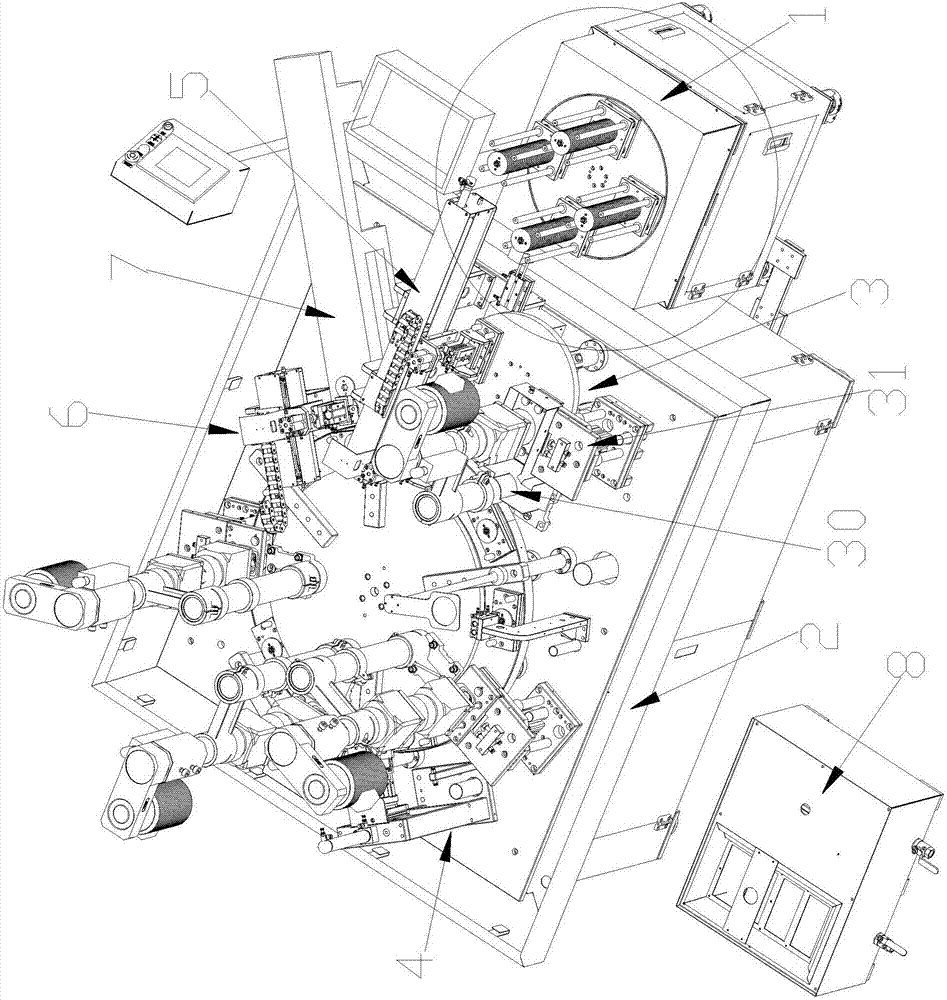

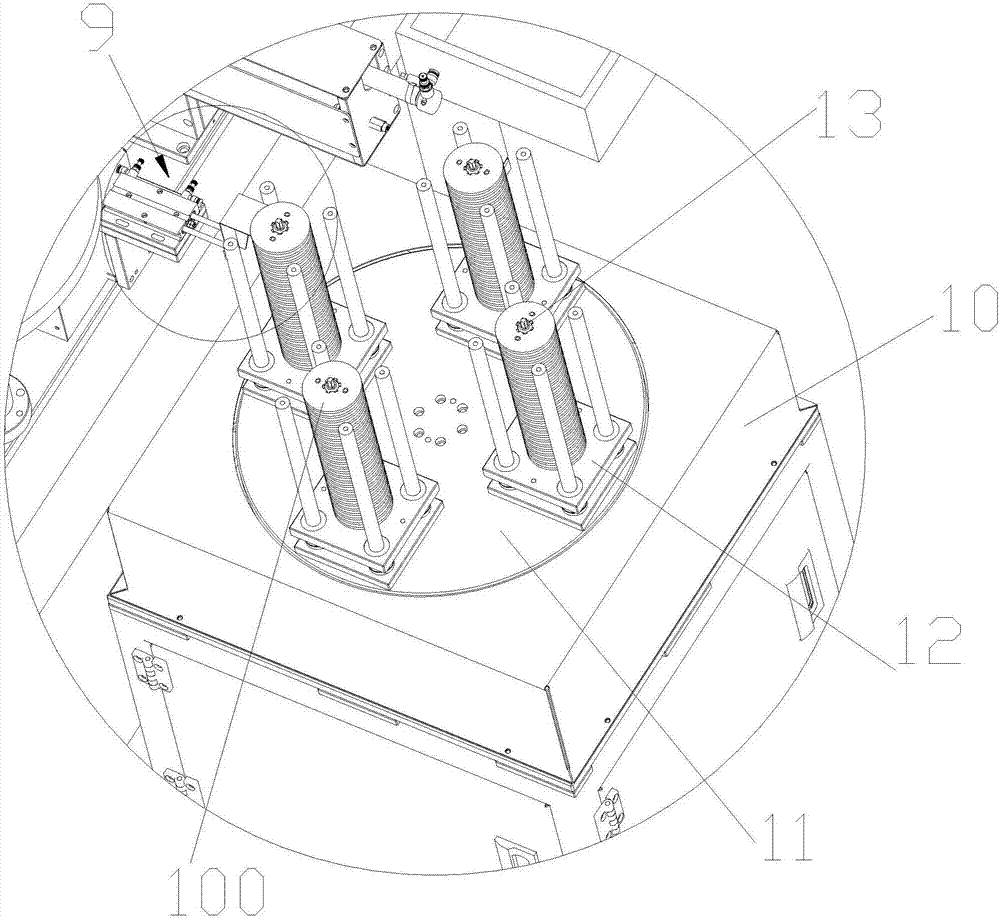

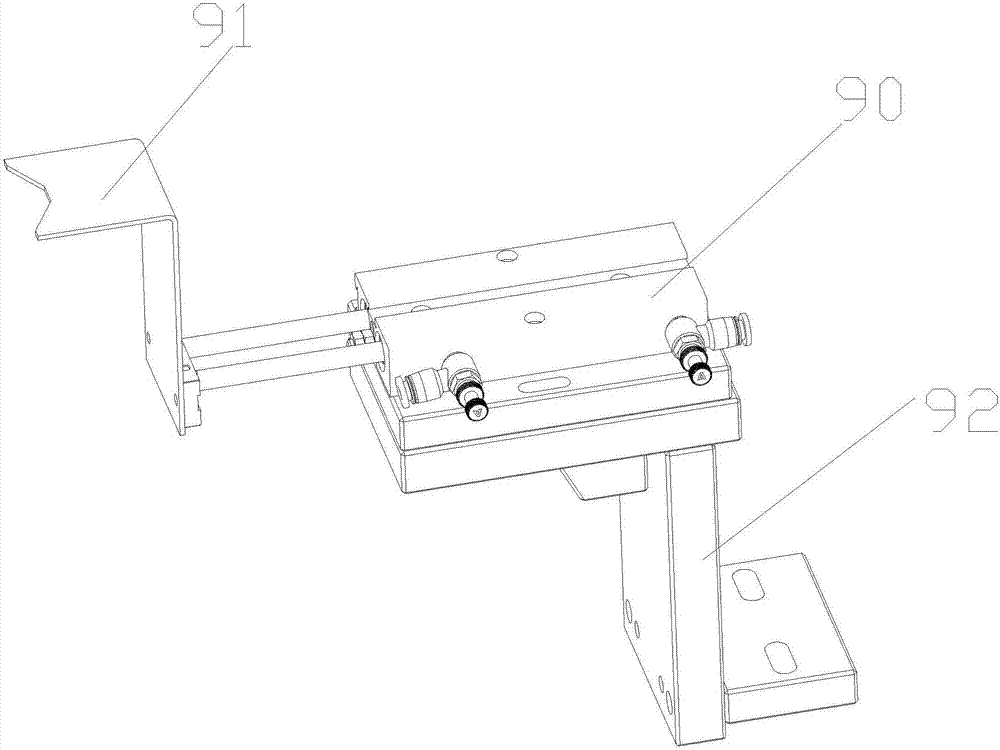

[0032] as attached figure 1 The shown integrated processing equipment for a motorcycle sprocket according to the present invention includes: a turntable magazine automatic feeding device 1, a frame 2, a drilling device 3, a chamfering tapping device 4, a single connecting rod double Arm manipulator device 5, finished product unloading manipulator 6 and belt line swinging device 7; the turntable magazine automatic feeding device 1 is located on one side of the frame 2; the drilling device 3 and the chamfering tapping device 4 are arranged oppositely On the frame 2; one side of the drilling device 3 is provided with a single-link double-arm manipulator device 5 positioned on the frame 2; Material manipulator 6; below the finished product unloading manipulator 6, there is a belt line swinging device 7 on the frame 2; the product is loaded through the turntable magazine automatic feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com