Bobbin winder of sewing machine

A bobbin winder and sewing machine technology, applied in the direction of bobbin winding, sewing equipment, sewing machine components, etc. in the sewing machine, can solve the problems of difficult to control the bobbin thread quantity, low winding precision, large error, etc., to improve the quality of finished products , Improve work efficiency, small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

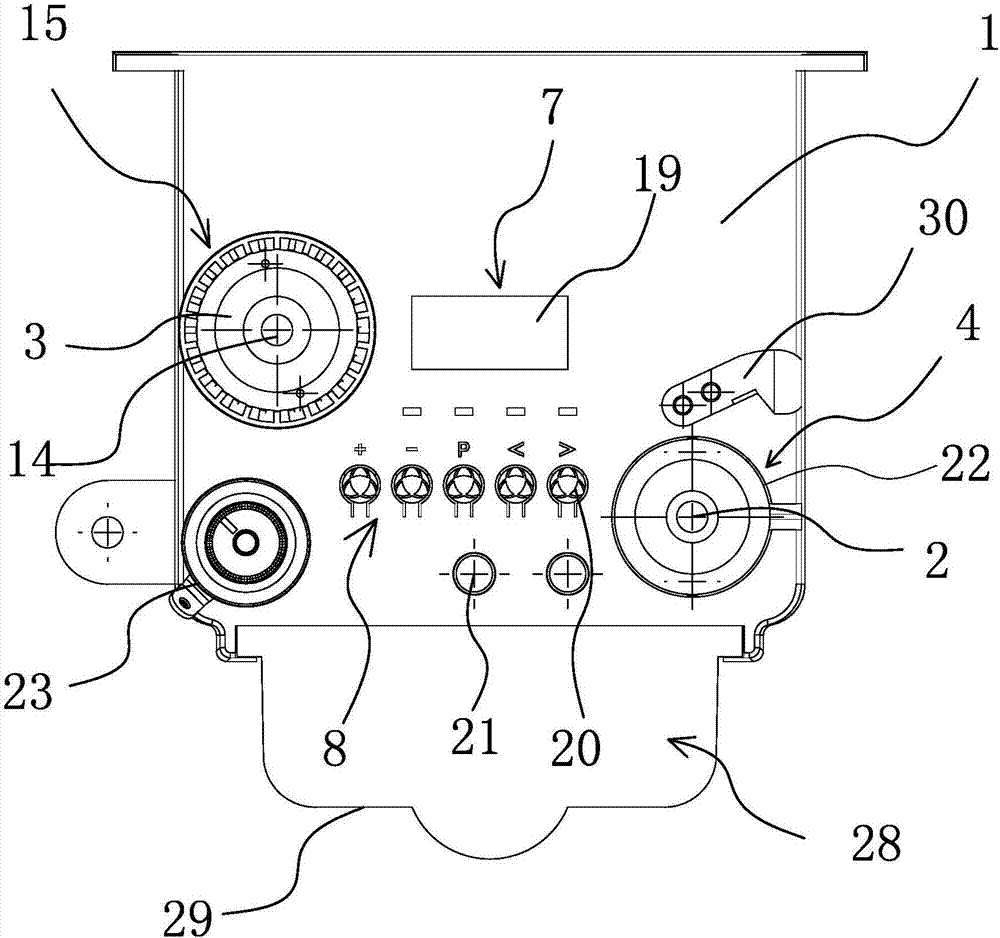

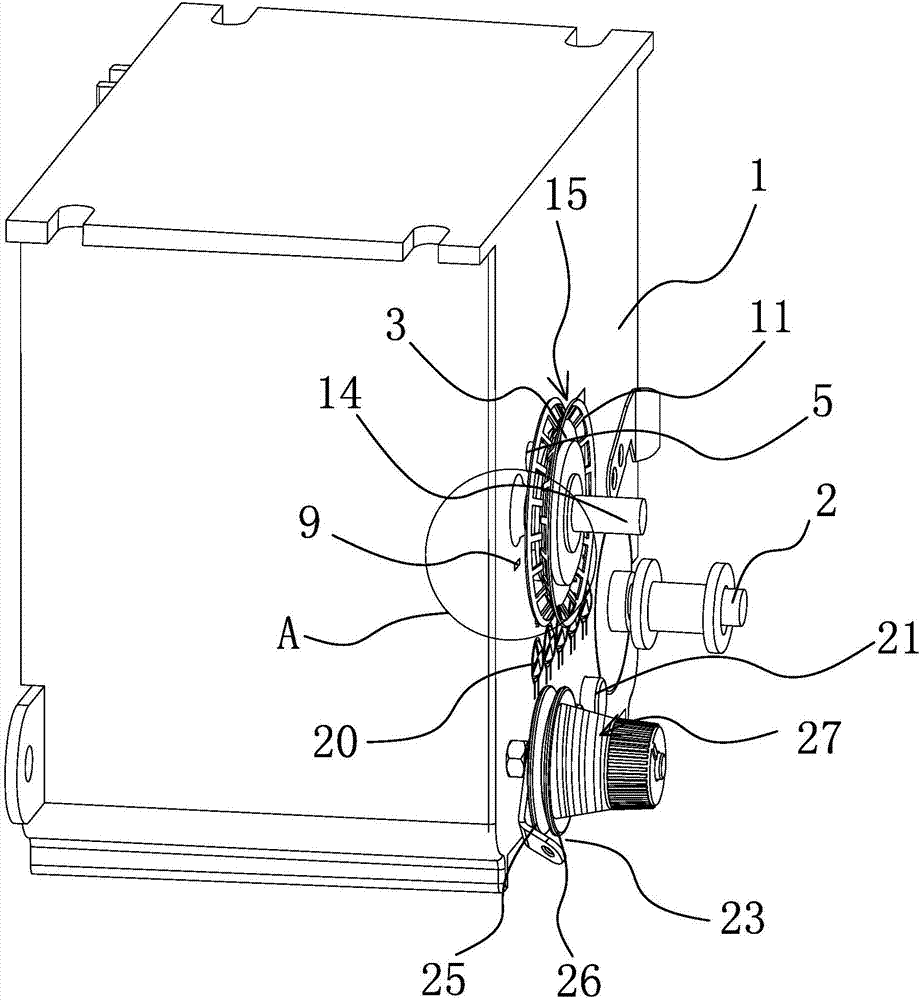

Embodiment 1

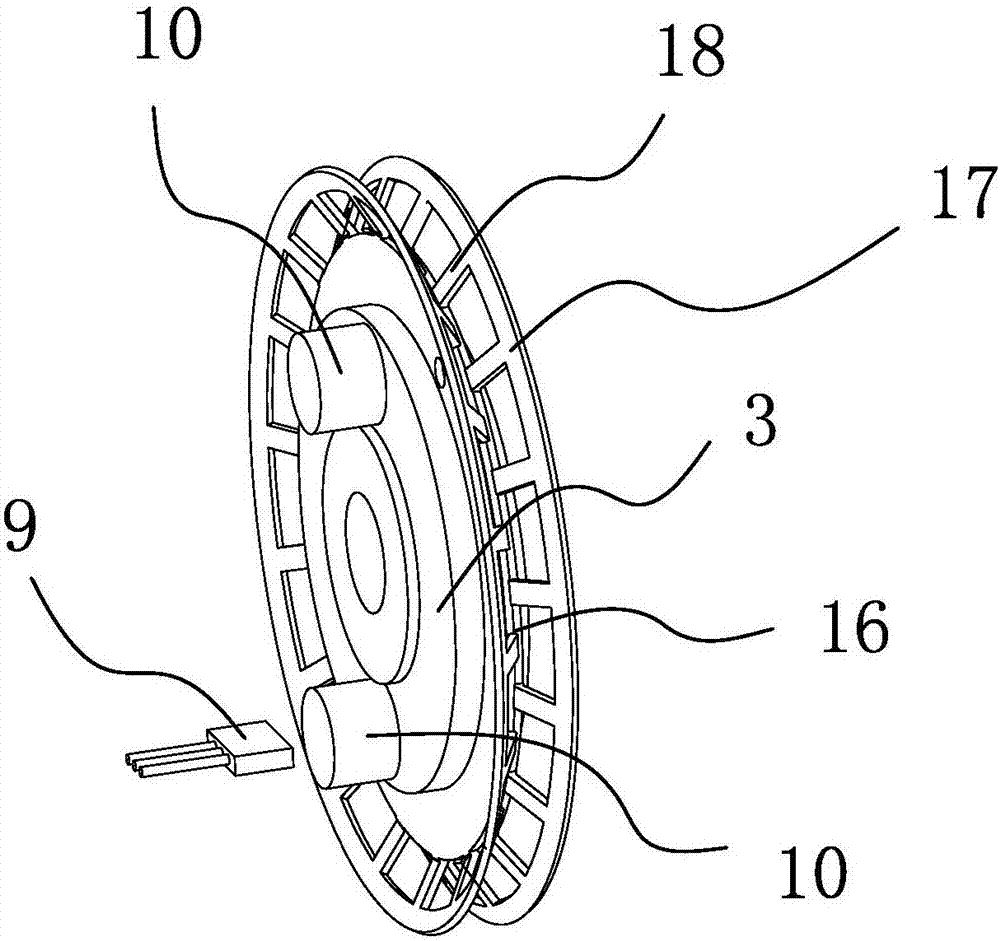

[0031] Such as Figure 1-7 As shown, the sewing machine winder includes a machine base 1, on which a bobbin installation shaft 2 and a counting rotating body 3 are rotatably connected. 3 is provided with a signal acquisition mechanism 5 capable of collecting and counting the number of rotation signals of the rotating body 3, the signal acquisition mechanism 5 and the rotation drive mechanism 4 are connected to the signal processing circuit 6 respectively, and the signal processing circuit 6 is connected with a cable length prompt module 7 And control module 8, adopt counting rotating body 3 to rotate number of laps and record length can get rid of the influence that directly measures bobbin rotation cycle counting precision insufficient, reason is that counting rotating body 3 is not subject to wire rod winding more, and the wire of every rotation The longer the impact, the counting rotating body 3 rotates a constant length across the line, so the length measurement is more ac...

Embodiment 2

[0040] Such as Figure 8 As shown, the working principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the signal acquisition mechanism 5 here includes at least one photoelectric sensor 11 connected to the signal processing circuit 6 and at least one sensor installed on the counting rotating body 3 The light blocking body 12, the photoelectric sensor 11 is arranged on the base 1, the photoelectric sensor 11 has a notch 13 with a size larger than the light blocking body 12, and a transmitter and a receiver are respectively arranged on both sides of the notch 13, and the light blocking body The number of 12 is multiple, and each light-blocking body 12 is evenly distributed on the same circle with the rotation center of the counting rotating body 3 as the center, and is calculated by the number of times that the light-blocking body 12 passes between the transmitter and the receiver in the slot 13 The number of turns of the rotating body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com