Drill assisted jack-up platform spud shoe

A self-elevating platform and drill bit technology, applied in construction, artificial island, infrastructure engineering and other directions, can solve problems such as difficulty in inserting and pulling out piles, and achieve the effects of reducing the difficulty of inserting piles, reducing sediment resistance and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

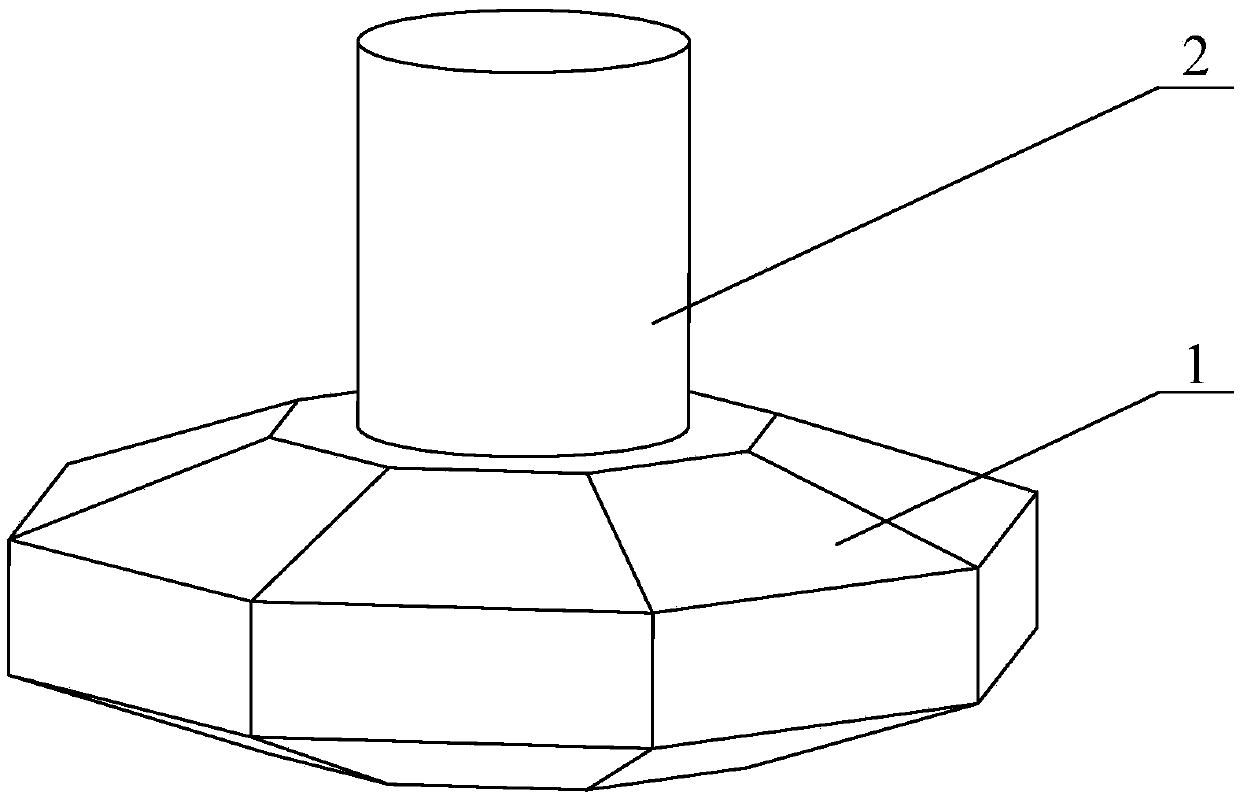

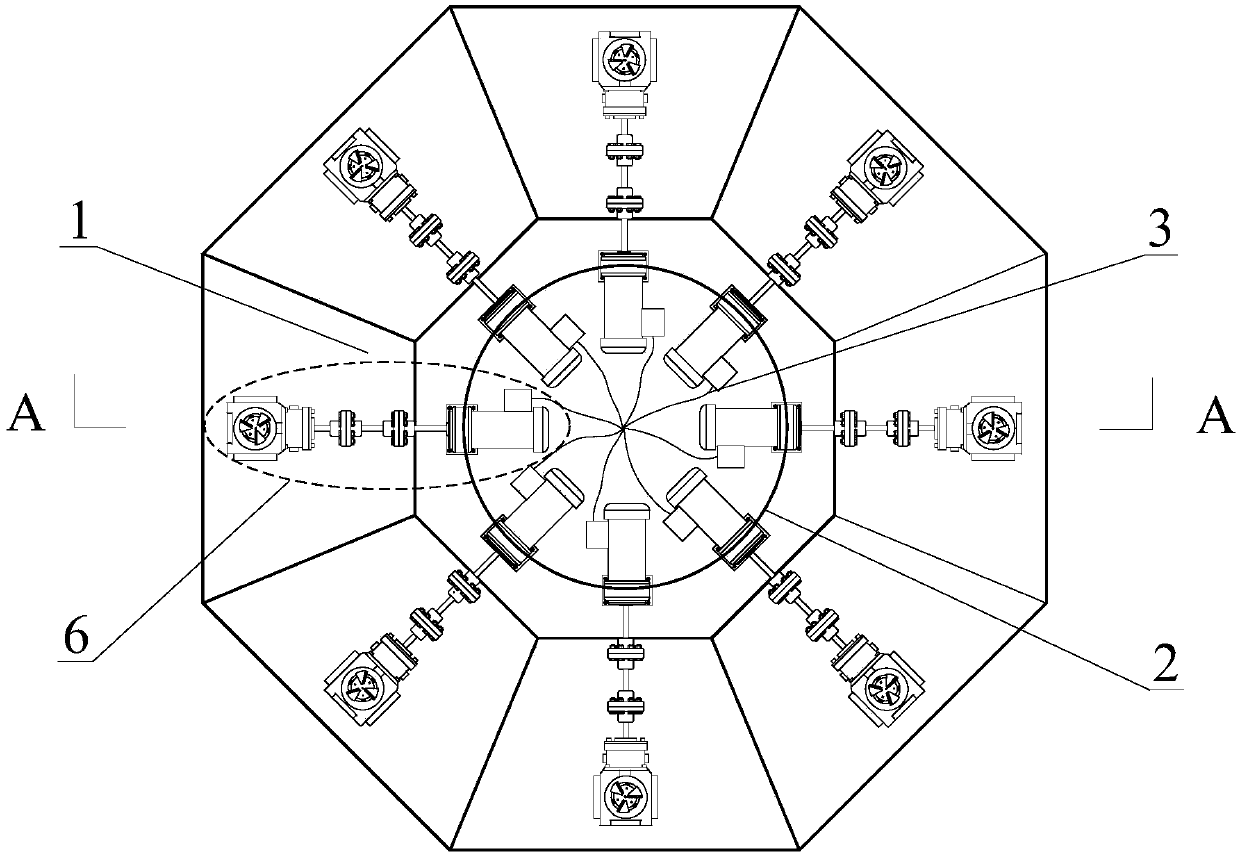

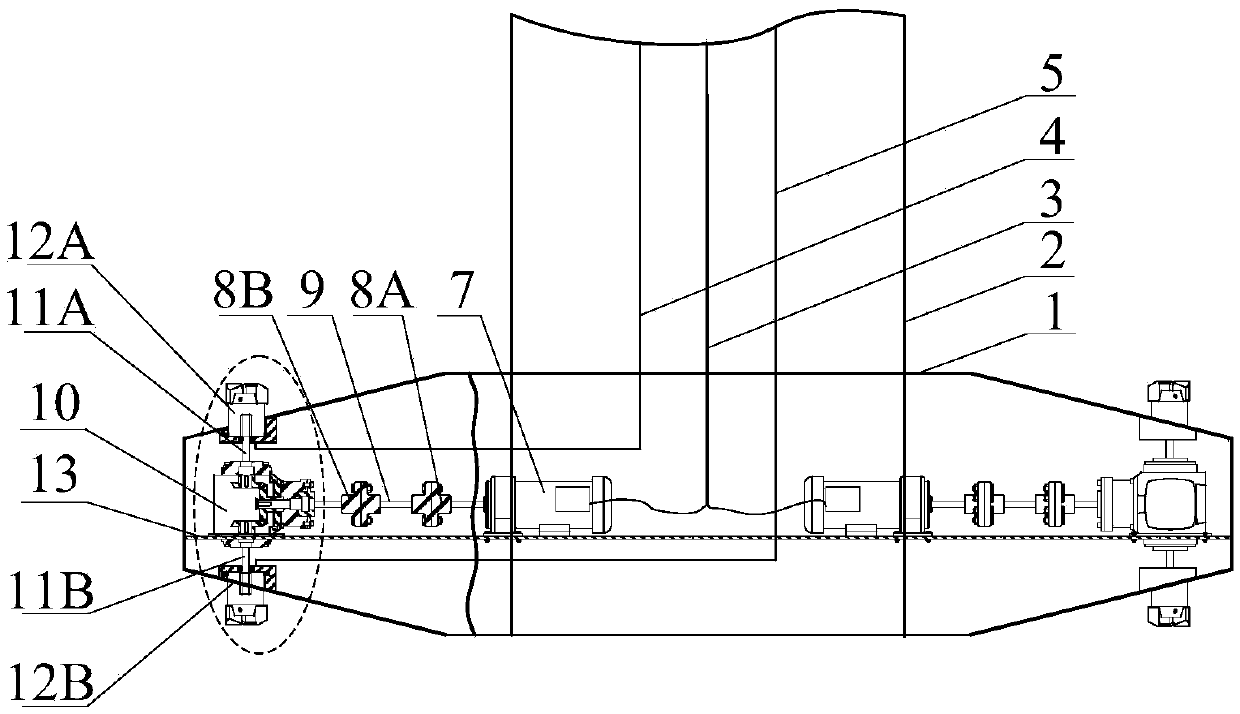

[0018] Such as Figure 1 to Figure 5 As shown, the spud shoe of the drill-assisted self-elevating platform includes: a spud shoe main body 1, which is located at the lower end of the spud leg 2, and a drill bit can be installed on the upper or / and lower surface of the spud can main body 1 according to different seabed topography.

[0019] The drill bit is a spray-type roller cone bit, and a water outlet hole is arranged on the outer surface of the drill bit; by adjusting the position and quantity of the drill bit to be suitable for different spud cane structures, the drill bits are arranged uniformly or unevenly along the circumference of the spud can main body; The drill bit is arranged on the surface of the spud can main body 1, and the gray ring is used for double-layer sealing between the spud can main body 1 and the spud can main body 1.

[0020] Power lines 3 and water supply pipes are arranged inside the spud shoe main body 1 and pile legs 2, and voltage and high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com