Preparation method of cement based double-backing rock wool composite thermal insulation board for external wall

An external wall thermal insulation board, cement-based technology, applied in thermal insulation, chemical instruments and methods, household walls and other directions, can solve the problems of rock wool thermal insulation performance and strength decline, mildew and other problems, to save social labor costs, quality stability, optimization The effect of the wiping procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

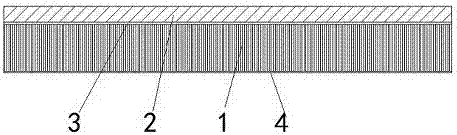

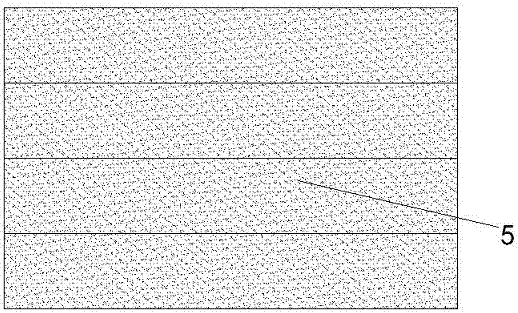

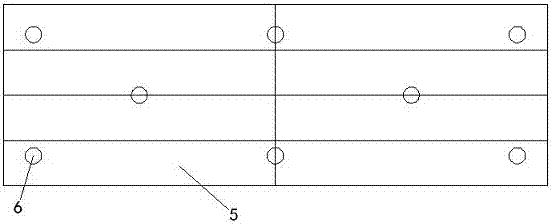

[0035] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] Such as Figure 1-5 Shown, a kind of cement-based double-backed rock wool composite exterior wall insulation board preparation method of the present invention, its steps are as follows,

[0037] 1) For cement-based backing board The inner surface is cleaned, then placed in a flat tire mold and coated with polyester glue;

[0038] 2) Select the thickness of the rock wool strip according to the energy-saving design requirements;

[0039] 3) Apply polyester glue to the bottom of multiple rock wool strips, and bond the bottom of the rock wool strips to the cement-based backing board on the inner surface;

[0040] 4) For cement-based backing board The inner surface is cleaned, then placed in a flat tire mold and coated with polyester glue;

[0041] 5) Apply polyester glue on the top of multiple rock wool strips, and bond the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com