Oil well wax removal device for petroleum drilling

A technology for oil drilling and oil wells, which is used in earth-moving drilling, wellbore/well components, cleaning appliances, etc. It can solve the problems of high wax content in crude oil and wax deposition in oil wells, so as to reduce the cost of wax removal, improve the efficiency of tool change, Avoid the effect of reducing the crude oil circulation channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

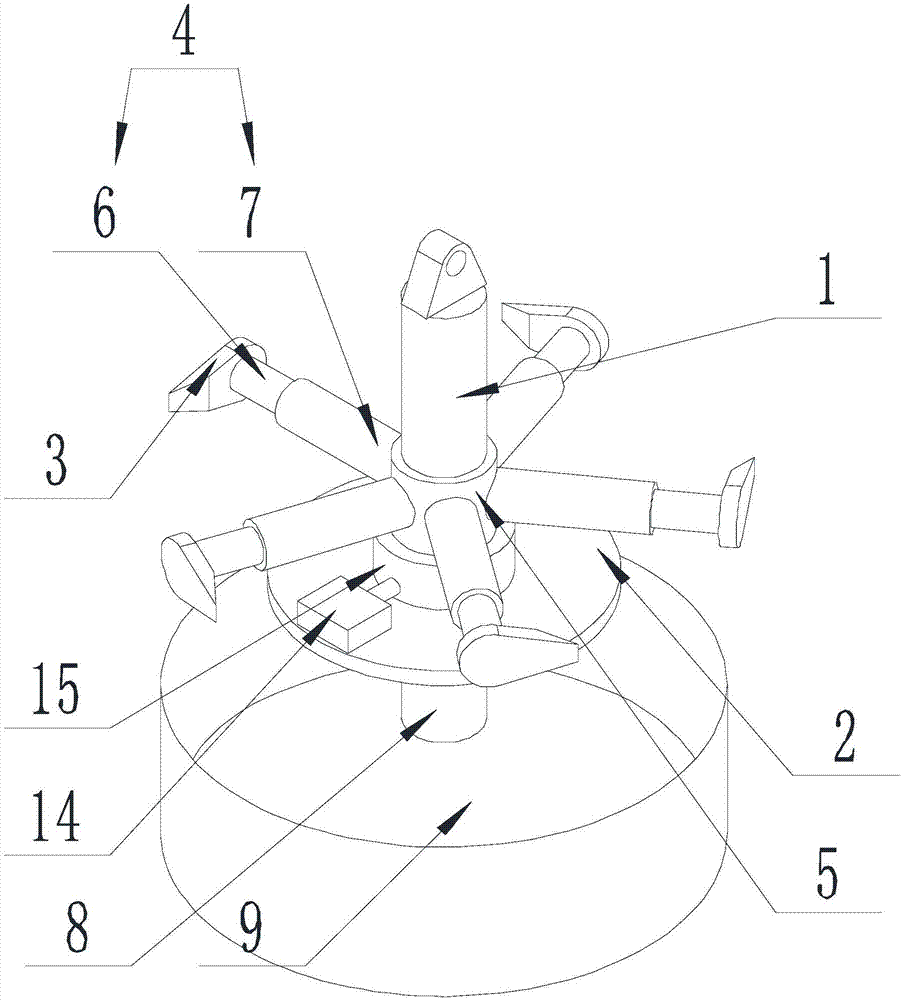

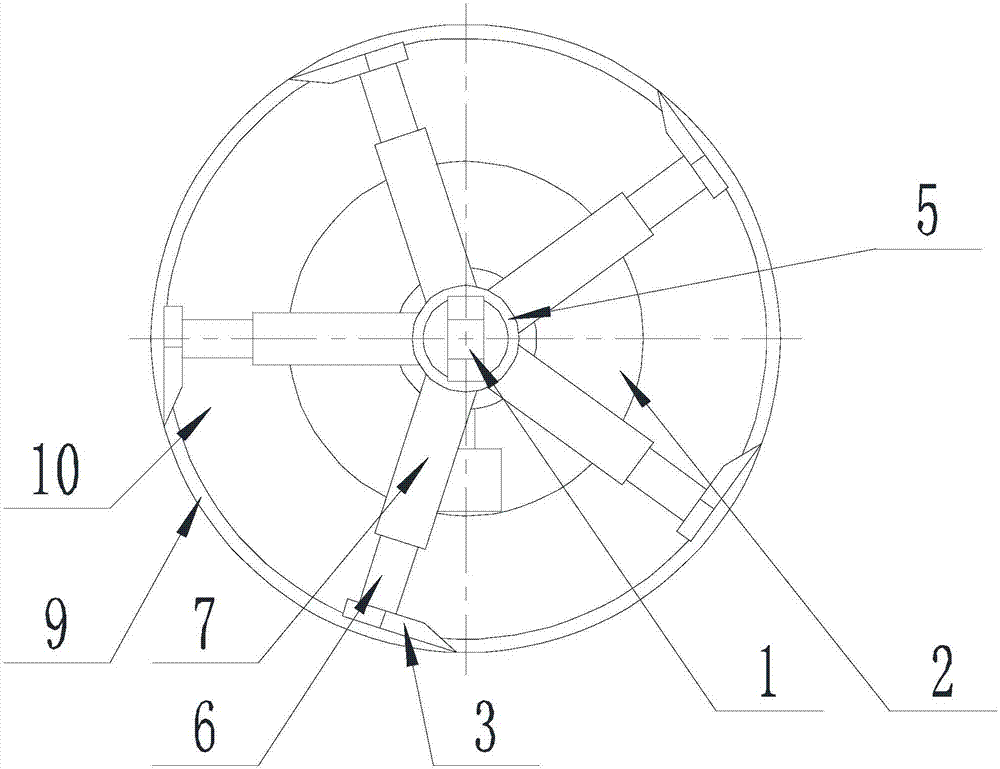

[0030] Such as Figure 1-Figure 4 As shown, the oil well dewaxing device for oil drilling of the present invention includes a suspension device and a wax removal assembly connected in sequence, the suspension device drives the wax removal assembly to move vertically, and the wax removal assembly includes a connecting shaft 1, a support plate 2. The scraper assembly and the driving device, one end of the connecting shaft 1 is connected to the suspension device, the other end of the connecting shaft 1 is connected to the support plate 2, the driving device is located on the upper surface of the support plate 2, and is connected to the scraper assembly , the driving device drives the scraper assembly to rotate along the axis of the connecting shaft 1 .

[0031] The scraper assembly includes a scraper 3, a connecting rod 4 and a drum 5 connected in sequence, one end of the connecting rod 4 is connected to the scraper 3, the blade of the scraper 3 is parallel to the axis of the dru...

Embodiment 2

[0035] The present invention is based on embodiment 1, and the present invention is further described.

[0036] Such as Figure 1-Figure 4 As shown, in the oil well wax removal device for oil drilling of the present invention, there are five scraper assemblies, and they are evenly arranged on the outer wall of the drum 5 with the axis of the connecting shaft 1 as the center line of symmetry. Setting multiple scraper assemblies can improve wax scraping efficiency and wax scraping effect.

[0037] Further, on the lower surface of the support plate 2, a support rod 8 coaxial with each other and a receiving tray 9 are arranged, the support rod 8 is coaxial with the connecting shaft 1, and one end of the support rod 8 is connected to the end of the support plate 2. The lower surface is connected, and the other end of the support rod 8 is connected with the receiving tray 9.

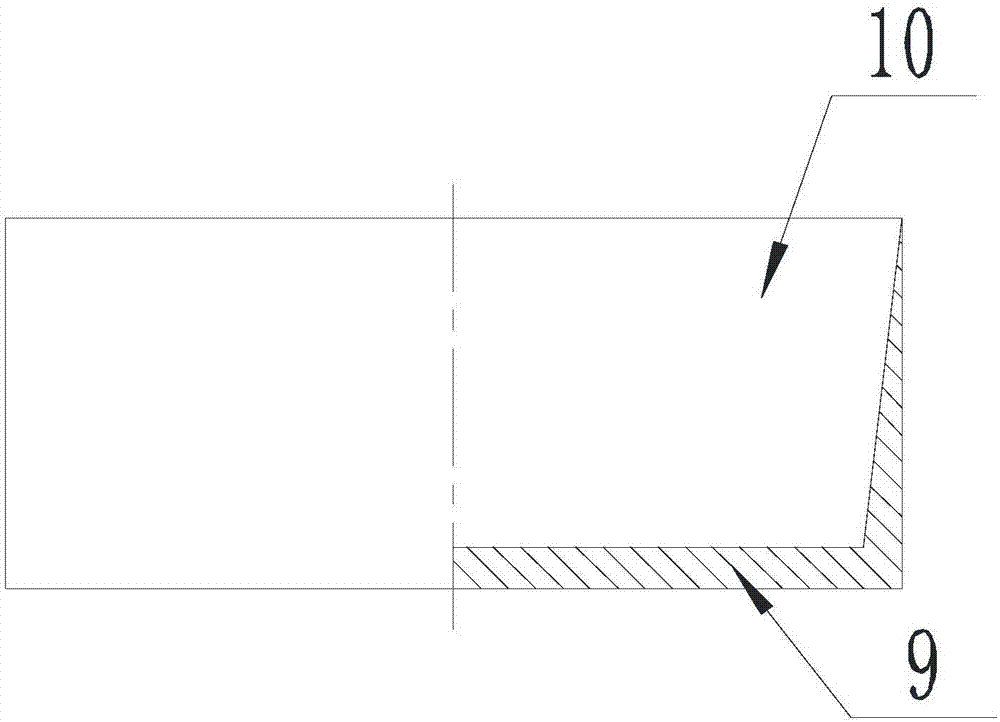

[0038] A groove 10 is arranged on the upper surface of the material receiving tray 9, the groove 10 is co...

Embodiment 3

[0041] The present invention further describes the suspension device on the basis of Embodiment 1.

[0042] Such as Figure 1-Figure 4 As shown, the oil well wax removal device for oil drilling of the present invention, the suspension device includes a fixed wheel 12, a winch 11 and a steel wire rope 12, one end of the steel wire rope 12 is connected to the winch 11, and the other end of the steel wire rope goes around the fixed wheel 12 After connecting with the connecting shaft 1, the winch 11 makes the connecting shaft 1 move along the axis perpendicular to the horizontal plane by retracting and unwinding the wire rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com