Jet assisted shield tunneling machine for noncircular-section tunneling construction

A shield machine and cross-section technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of extrusion into the inner wall of the soil bin, high manufacturing and assembly precision requirements, and high cost, so as to simplify the structure of the shield machine and avoid poor versatility , Promote the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

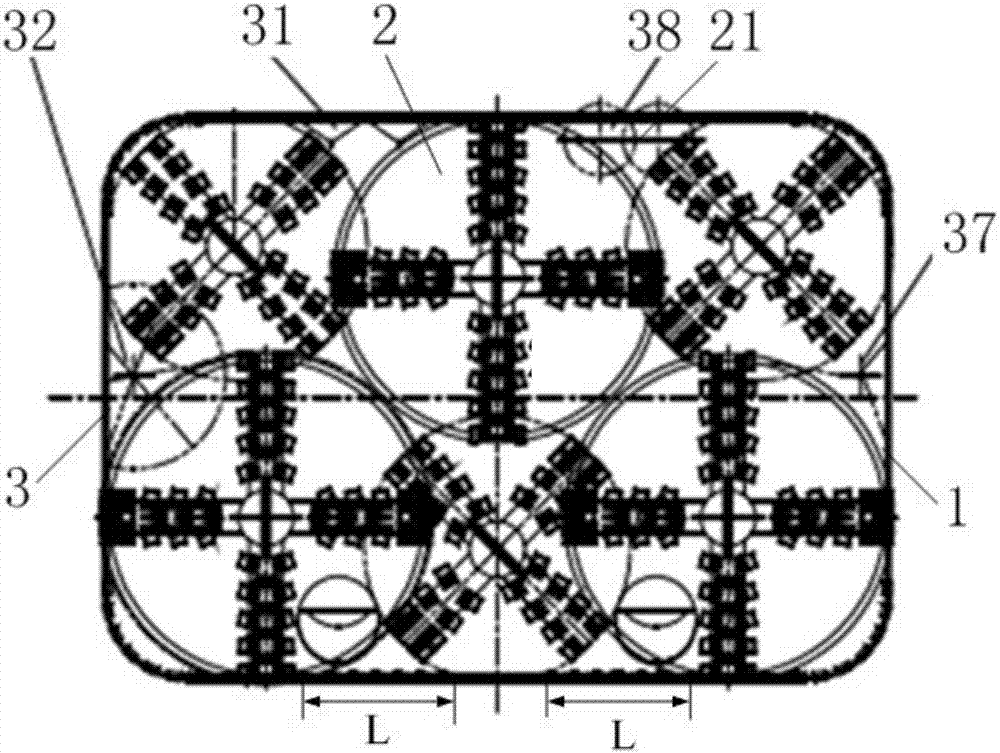

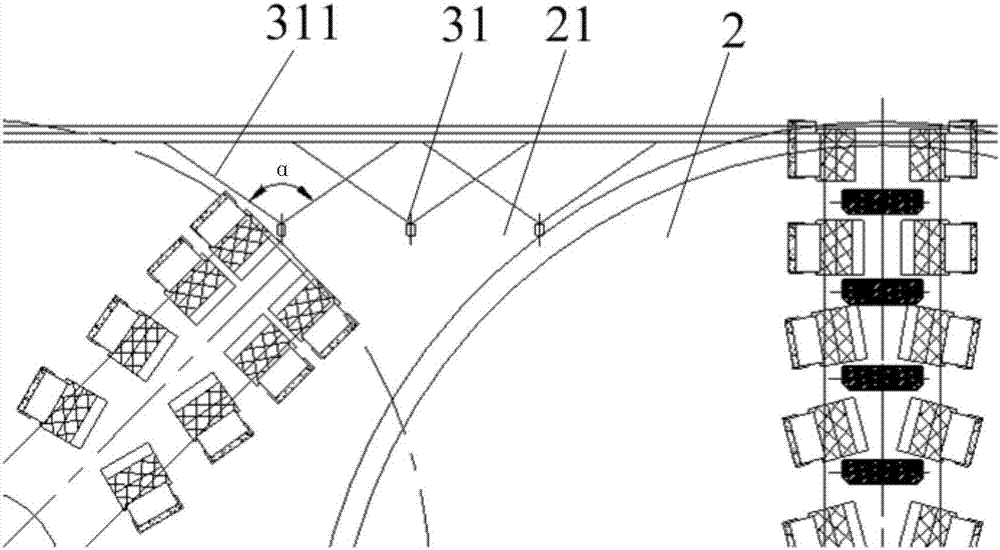

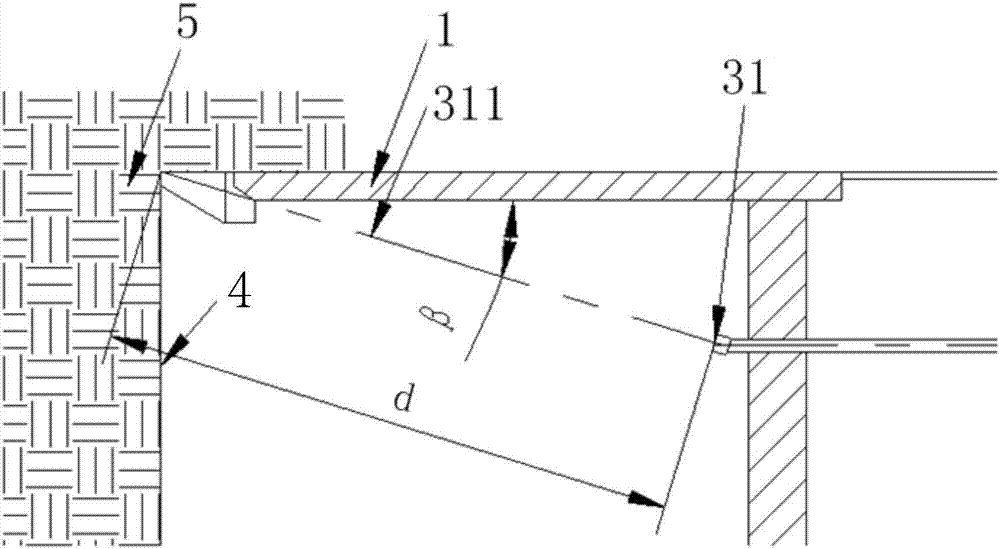

[0031] Such as figure 1 As shown, the jet-assisted shield machine for non-circular cross-section excavation construction in this embodiment includes a front shield 1, a plurality of cutter heads 2 and a jet flow assembly 3, and a plurality of cutter heads 2 are arranged on the end face of the front shield 1, and the jet flow The assembly 3 is also arranged on the end face of the front shield 1, and the jet assembly 3 and the cutter head 2 are arranged in a staggered manner. The spray stroke of the jet assembly 3 covers the cutting blind area 21 of the cutter head 2. 5 Strip broken from the formation and discharge. In the present invention, a jet assembly 3 is provided on the end face of the front shield 1, and the jet assembly 3 and the cutter head 2 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com