Automatic liquid flow regulating valve

A liquid flow and flow regulating valve technology, which is applied in the direction of valve devices, engine components, and cocks including cut-off devices, can solve the problems of inconvenient connection, difficult promotion, and many connecting lines of control valves on control panels, and achieve excellent adjustment accuracy and Stability of work, simple control of flow regulation, and simple regulation circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

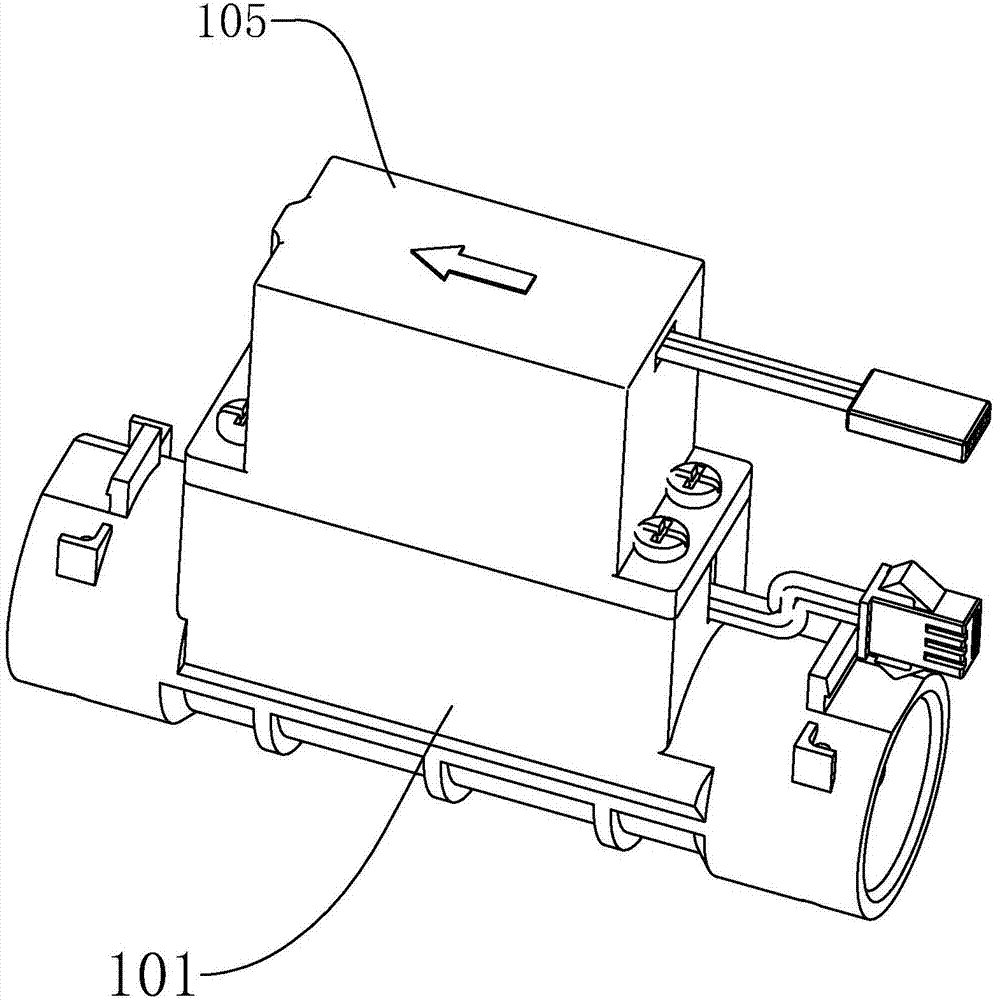

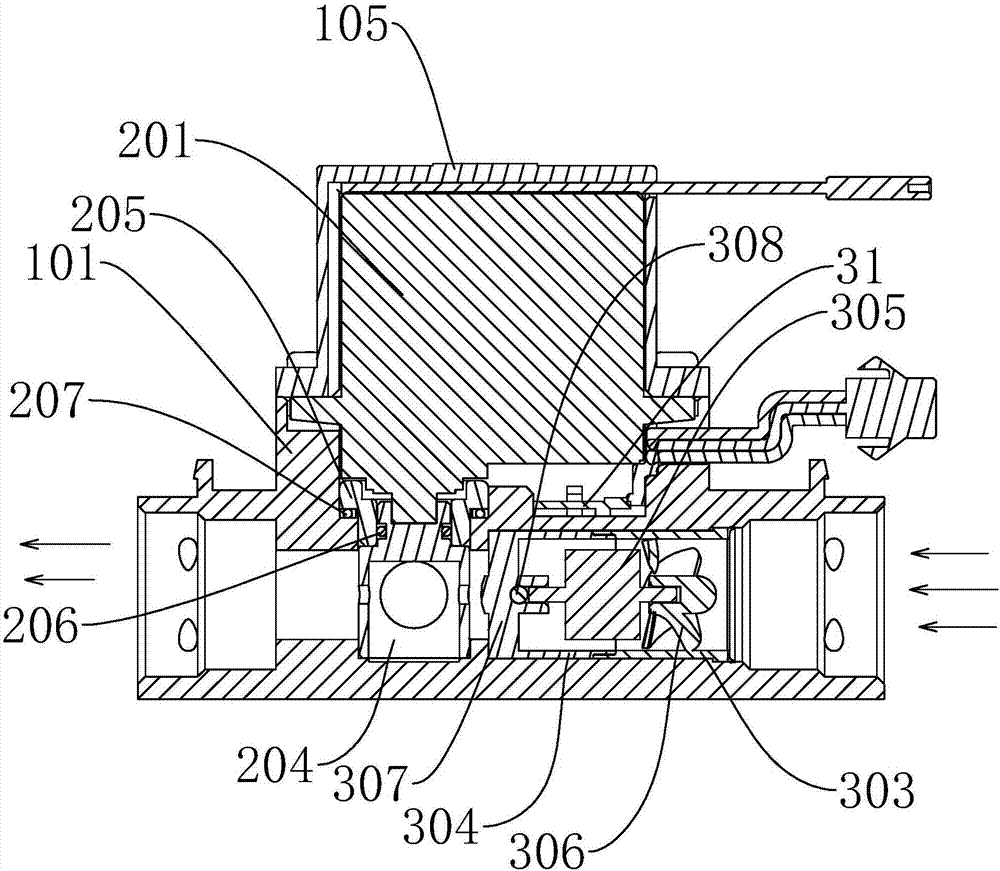

[0032] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a liquid flow automatic regulating valve includes a regulating valve body, and the regulating valve body includes a valve body 101, a flow information collection mechanism, and a flow regulating mechanism. A fluid channel is opened in the valve body 101, and the flow information collecting mechanism and the flow regulating mechanism are arranged in the fluid channel.

[0033] like figure 2 As shown, in this embodiment, the fluid passage runs from the right side of the valve body 101 to the left side of the valve body 101, and the fluid enters from the right side of the valve body 101, passes through the flow information collection mechanism and the flow adjustment mechanism, and flows from the valve body 101 left output.

[0034] In this embodiment, the flow information collection mechanism preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com