Transferable patterned conductive thin film structure and patterning method thereof

A conductive thin film and transfer pattern technology, applied to the conductive layer, circuit, electrical components and other directions on the insulating carrier, can solve the problem of poor adhesion between nano-metal materials and substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

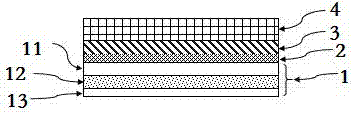

[0054] The structure of the transferable patterned conductive film is shown in the attached figure 1 As shown, a release film, an adhesive layer, a flexible substrate, an adhesion enhancement layer, a conductive layer and a photosensitive film layer are stacked sequentially from bottom to top.

Embodiment 2

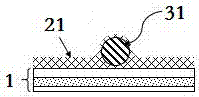

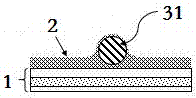

[0056] The general preparation method of transferable patterned conductive film is to first prepare conductive ink, which is specifically composed of polymer molecules, nano-metal materials, and solvents, and then attached to a flexible substrate. figure 2 As shown, a composite layer of the polymer layer and the nano-metal material is formed at this time, and then by adding a cross-linking agent to the polymer layer, the cross-linking agent reacts with the polymer molecules in the polymer layer to form an adhesion-enhancing layer, that is attached image 3 shown. Finally, the prepared photosensitive film layer is attached to the conductive layer to complete the preparation of the transferable patterned conductive film.

Embodiment 3

[0058] The patterning method of the transferable patterned conductive film is as follows: first, exposure is performed according to the set pattern, and after the exposure is completed, it is developed by a developer. At this time, the unexposed photosensitive adhesive layer still exists, and the exposed photosensitive adhesive layer still exists. The adhesive layer is completely removed to expose the conductive layer. At this time, the etching process is performed again, and the etching solution will corrode the exposed conductive layer. After the etching is completed, a glue removal process is performed. After the glue removal is completed, the patterning of the conductive layer is completed. Finally, when it is necessary to transfer the patterned conductive film, it is only necessary to tear off the release film and combine the adhesive layer with the target substrate. Figure 4 And attached Figure 5 shown, it is done. (Whether to add examples to make photosensitive dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com