An ultra-high resolution fluorine-containing oxygen-containing block copolymer and its preparation method and application

An ultra-high-resolution, block copolymer technology, applied in the field of ultra-high-resolution fluorine-containing oxygen-containing block copolymers and their preparation, can solve problems such as hindering application, high defect rate, and difficulty in meeting production requirements, and achieves Effects of high etch contrast, defectivity reduction, and excellent phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also includes the preparation method of the above-mentioned ultra-high resolution fluorine-containing oxygen-containing block copolymer, comprising the following steps:

[0063] S1. Select a homopolymer monomer and a modified monomer, and polymerize the homopolymer monomer into a homopolymer, wherein the homopolymer monomer is selected from: alkoxy-substituted styrene compounds , Vinyl phenol ester compounds, methacrylate phenol ester or acrylate phenol ester compounds containing ester groups in the aryl group, the substitution is ortho-, inter-or mono-substitution or multi-substitution;

[0064] The modified monomer is a compound containing the following structural units: fluorine-containing methacrylate compounds, fluorine-containing styrene compounds;

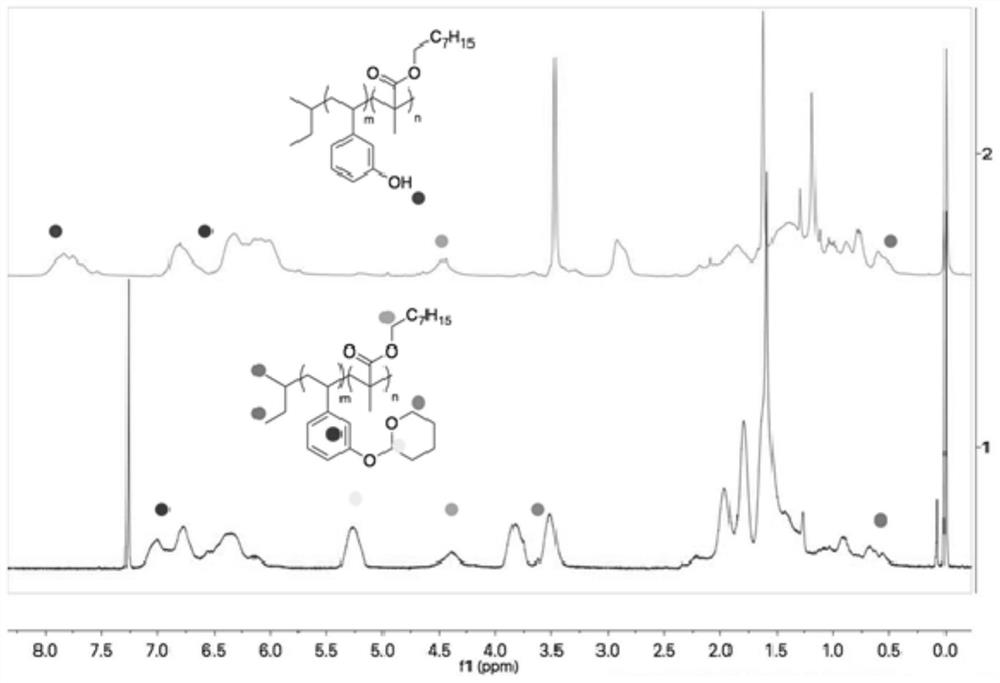

[0065] S2. Mix the homopolymer and the modified monomer prepared in the step S1 in proportion, polymerize through a polymerization reaction, and then deprotect to obtain the ultra-high resolution...

Embodiment 1

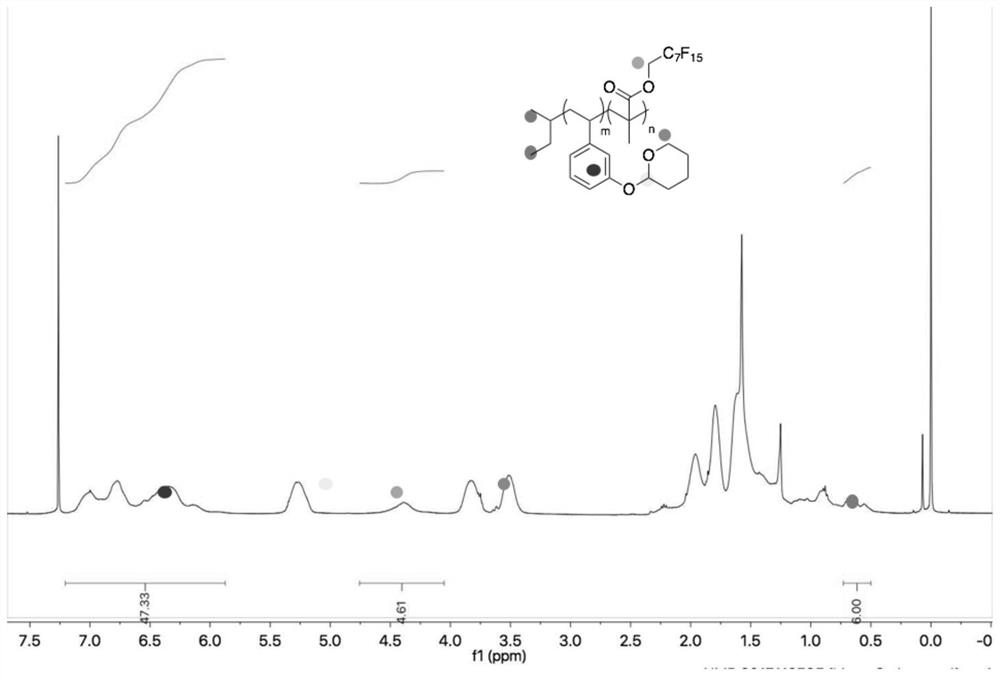

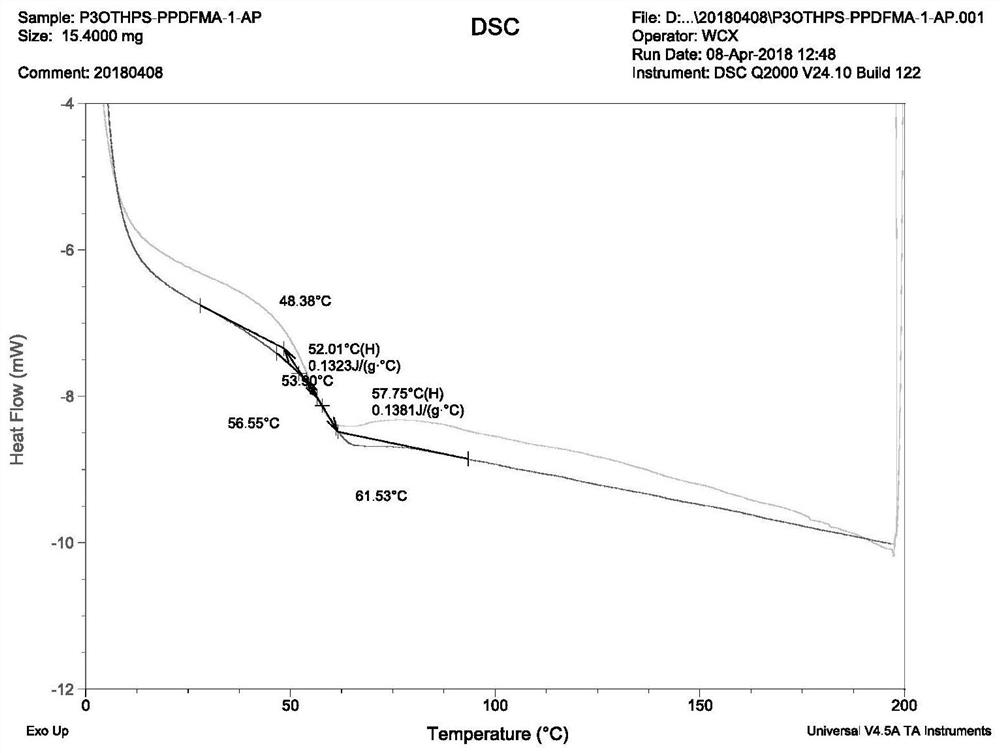

[0070] Embodiment 1 of the present invention is: an ultra-high resolution fluorine-containing oxygen-containing block copolymer and its preparation method, the precursor of the block copolymer is P3OTHPS-b-PPDFMA-1, and the P3OTHPS-b -PPDFMA-1 is prepared by anionic polymerization.

[0071] 3ml 3OTHPS Dissolve in 35mL tetrahydrofuran, add dibutylmagnesium solution (1M, solvent is n-hexane) and raise the temperature to 40°C for 0.5h, and transfer the treated mixture to a reaction flask. The reaction bottle was returned to room temperature, stirred evenly, and then placed in a cold bath at -80°C for 15 minutes. Add 0.65mL sec-BuLi (1.3M, the solvent is n-hexane), and keep the reaction at -80°C for 15min. The dried fluoromethacrylate ( 2.5ml) was dropped to -60°C, dropped into the reaction system, and kept at -80°C for 40 minutes. The product was precipitated in ethanol to give 4.5 g of a white solid.

[0072] Get the white precipitation that above-mentioned operation make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com