Ultrahigh-resolution anti-etching metal-containing block copolymer as well as preparation and application of same

A block copolymer and ultra-high resolution technology, which is applied in the field of ultra-high resolution anti-etching block copolymers containing organic metals, can solve the problem of inability to obtain microphase separation structure, affect the application of DSA materials, and the impossibility of doping process Controllability and other issues, to achieve the effect of reducing assembly defect rate, convenient pattern transfer, and good etching contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

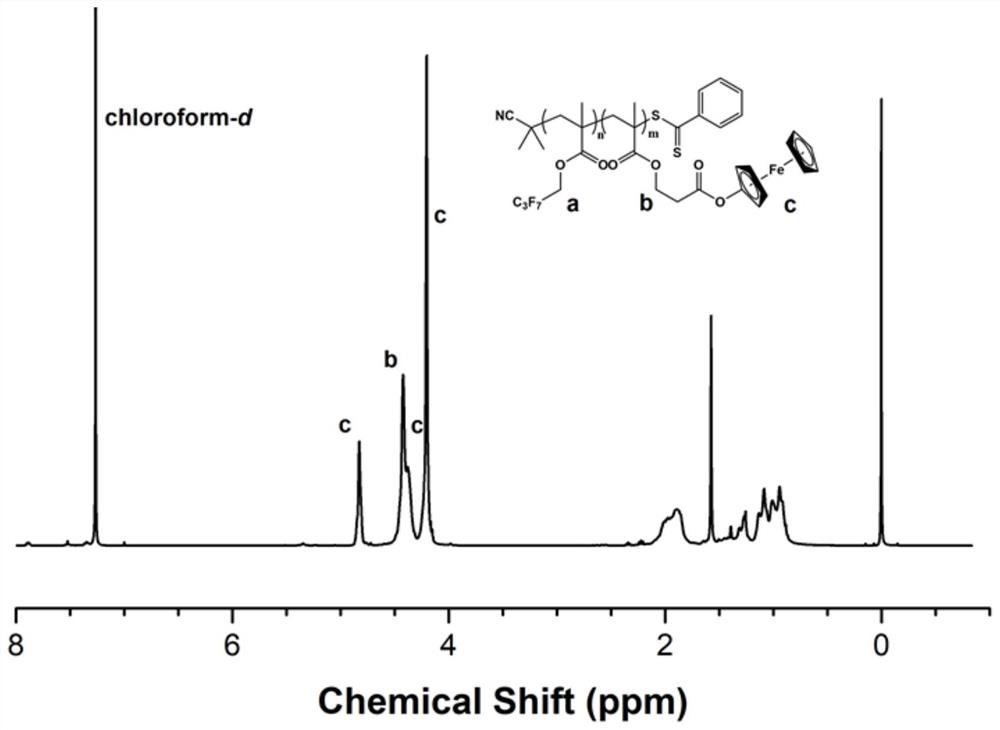

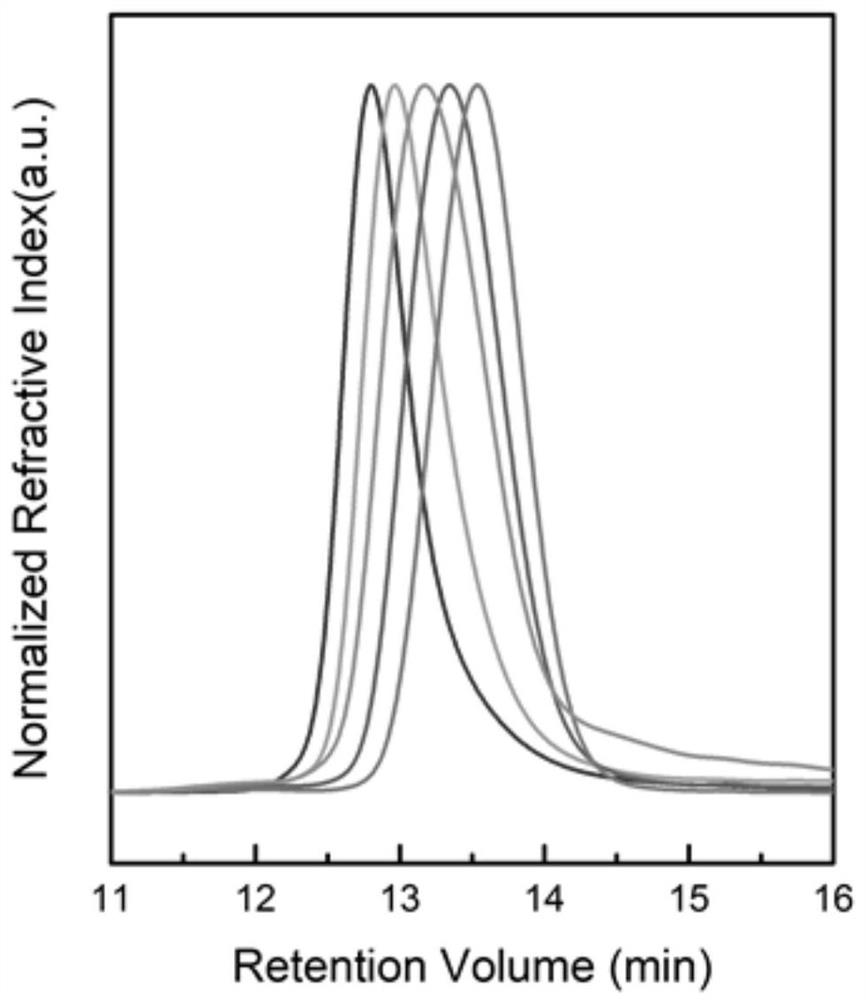

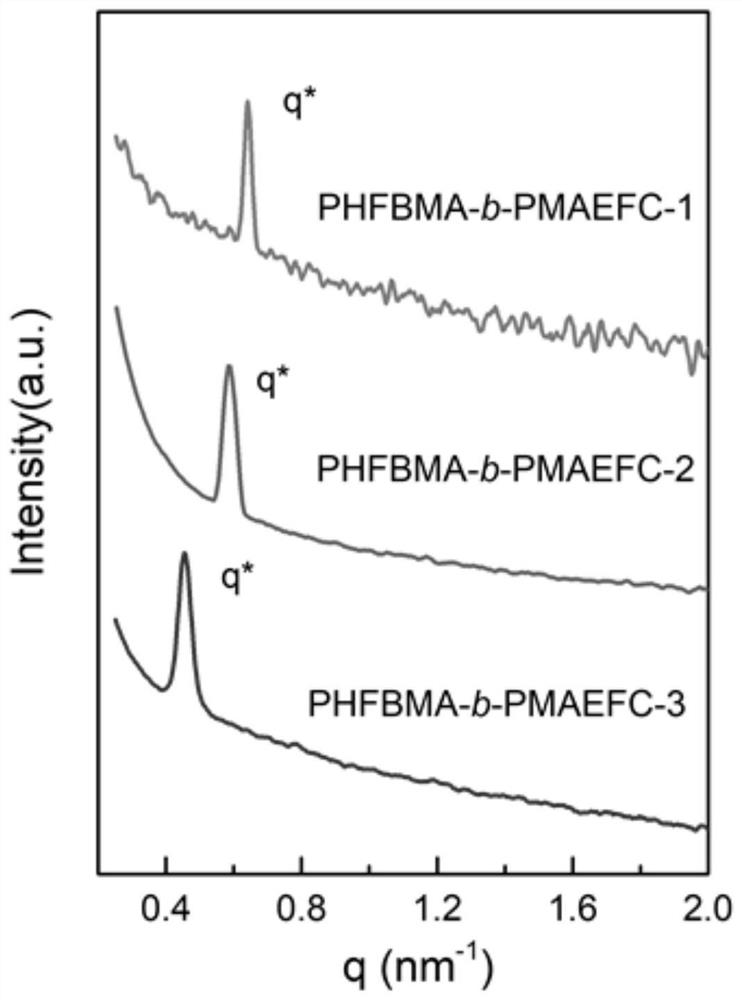

[0069] A polymer nanomaterial for ultra-high resolution metal-containing DSA. The material includes a block copolymer. The block copolymer is composed of a metal-containing block and a fluorine-containing block. The RAFT method is used to prepare the scratch-resistant Corroded block copolymers in which 2-Cyano-2-propyl benzodithioate (CPDB) is used as chain transfer agent, azobisisobutyronitrile (AIBN) As an initiator, 1H, 1H-perfluorobutyl methacrylate (1H, 1H-Heptafluorobutylmethacrylate, HFBMA) as a monomer, and hexafluoroisopropanol as a solvent, HFBMA, CPDB, AIBN and hexafluoroisopropanol Put it into the Shrek reaction tube, after deoxygenation, react at 50-80°C for 2-30 hours, then precipitate it with methanol and dry it for later use. Use the obtained fluorine-containing monomer homopolymer as a macromolecular chain transfer agent, AIBN as an initiator, and ferroceneformyloxyethyl methacrylate (2-(Methacryloyloxy)ethylFerrocenecarboxylate, MAEFC) as a monomer, cyclohexa...

Embodiment 2

[0081] A polymer nanomaterial for ultra-high resolution metal-containing DSA. The material includes a block copolymer. The block copolymer is composed of two parts: a metal-containing block and a fluorine-containing block. The RAFT method is used to prepare the scratch-resistant Corroded block copolymers in which 2-Cyano-2-propyl benzodithioate (CPDB) is used as chain transfer agent, azobisisobutyronitrile (AIBN) As an initiator, 1H, 1H-perfluorobutyl methacrylate (1H, 1H-Heptafluorobutylmethacrylate, HFBMA) as a monomer, and hexafluoroisopropanol as a solvent, HFBMA, CPDB, AIBN and hexafluoroisopropanol Put it into the Shrek reaction tube, after deoxygenation, react at 50-80°C for 2-30 hours, then precipitate it with methanol and dry it for later use. Use the obtained fluorine-containing monomer homopolymer as a macromolecular chain transfer agent, AIBN as an initiator, ferrocenemethyl methacrylate (Ferrocenemethyl Methacrylatee, FMMA) as a monomer, and cyclohexanone as a sol...

Embodiment 3

[0091] A polymer nanomaterial for ultra-high resolution metal-containing DSA. The material includes a block copolymer. The block copolymer is composed of two parts: a metal-containing block and a fluorine-containing block. The RAFT method is used to prepare the scratch-resistant Corroded block copolymers in which 2-Cyano-2-propyl benzodithioate (CPDB) is used as chain transfer agent, azobisisobutyronitrile (AIBN) As an initiator, perfluorophenyl methacrylate (Pentafluorophenylmethacrylate, PFPMA) is used as a monomer, and hexafluoroisopropanol is used as a solvent. PFPMA, CPDB, AIBN and hexafluoroisopropanol are added to the Shrek reaction tube to remove oxygen. Finally, react at 50-80°C for 2-30 hours, and then precipitate and dry with methanol before use. Use the obtained fluorine-containing monomer homopolymer as a macromolecular chain transfer agent, AIBN as an initiator, and ferrocene formyloxyethyl methacrylate (2-(Methacryloyloxy)ethyl Ferrocenecarboxylate, MAEFC) as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com