Digital optical pulse generation device using piezoelectric ceramics feedback control

A piezoelectric ceramic and feedback control technology, which is applied in circuits, lasers, electrical components, etc., can solve the problems of long active mode-locked fiber laser cavity, poor stability of output pulse repetition frequency, and poor stability of output optical pulses. The effect of pulse optimization, high anti-damage threshold, and wide bandwidth response wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

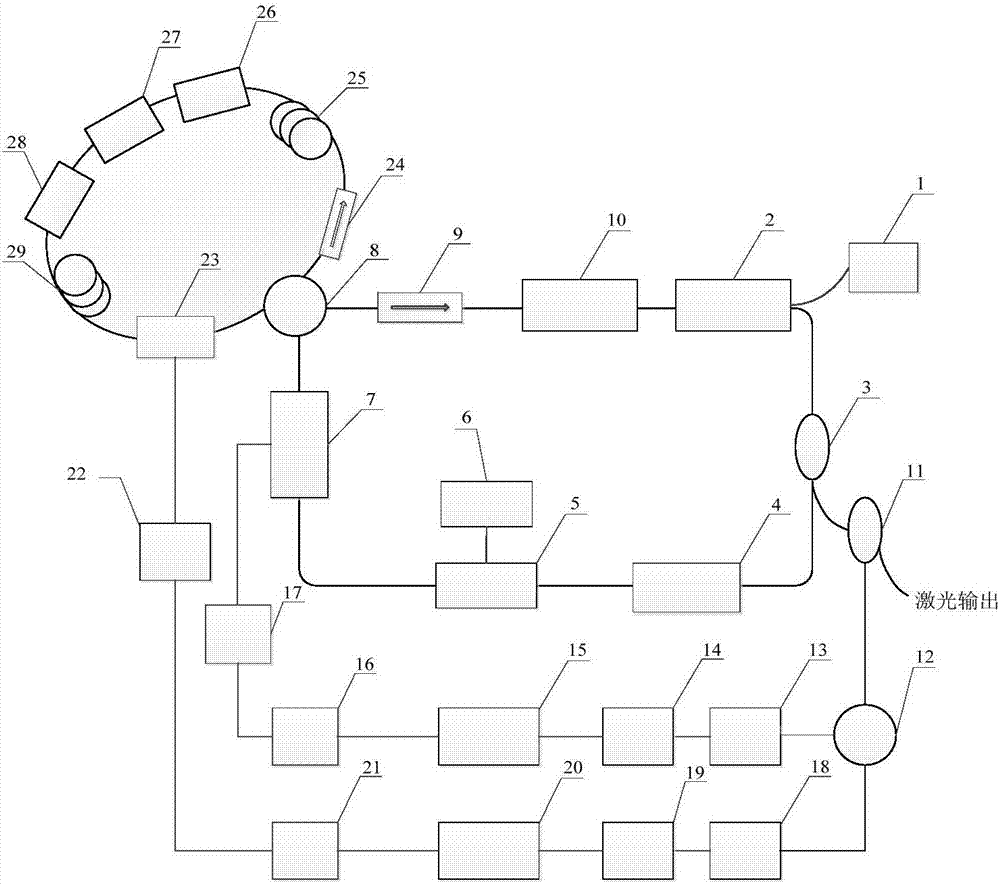

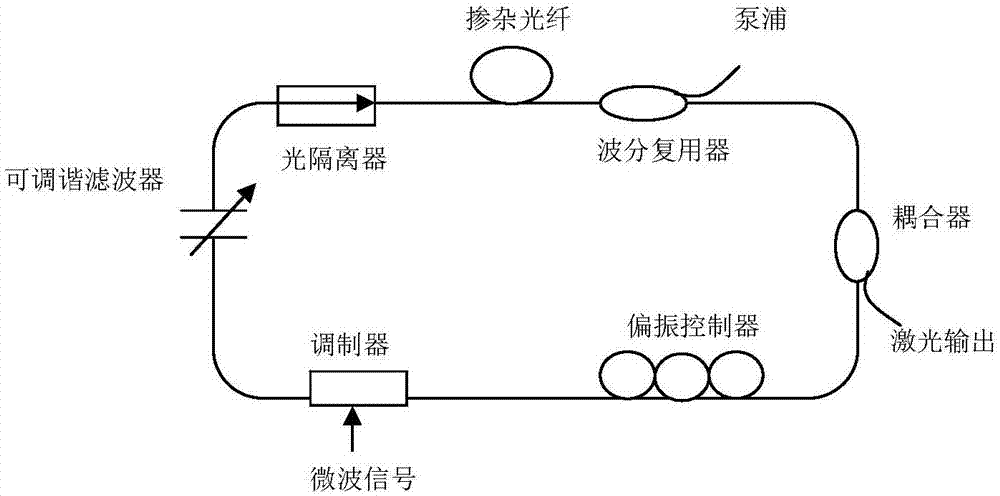

[0022] Embodiment 1: Concrete structure of the present invention

[0023] The structure of a digital optical pulse generator using piezoelectric ceramic feedback control according to the present invention is shown in the attached figure 1 As shown, its structure is that the pump light source 1 (980nm laser, the maximum output power is 1W) is connected to the 980nm end of the wavelength division multiplexer 2 (980 / 1550nm wavelength division multiplexer), and the wavelength division multiplexer 2 The 1550nm end is connected to the input end of the first optical coupler 3 (1×2 standard single-mode optical coupler with a splitting ratio of 10:90); the 10% output end of the first optical coupler 3 is connected to the first polarization controller 4 One end of the (pigtail type mechanical polarization controller) is connected, and the optical pulse of its output continues to run in the resonator of the active mode-locked fiber laser, and the 90% output end of the first optical coup...

Embodiment 2

[0025] Embodiment 2 Working process of the present invention and the effect of each main component

[0026] attached figure 1 In the structure shown, the pumping light source 1 is used as the laser pumping source of the whole system, and the pumping light source 1 enters the system through the wavelength division multiplexer 2; the first optical coupler 3 with a splitting ratio of 10:90 connects The running laser is divided into two parts, one part (90%) is output to the third optical coupler 11, and the other part (10%) continues to run in the resonator of the active mode-locked fiber laser; the third light splitting ratio is 40:60 The coupler 11 divides the laser light output by the first optical coupler 3 into two parts, one part (60%) is used as the laser output of the whole system, and the other part (40%) is output to the fourth optical coupler 12 as a feedback signal of the system; The first polarization controller 4 and the second polarization controller 28 are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com