Oil-bag emulsion type foundation emulsion and preparation method thereof

A technology of emulsion type and foundation, which is applied in the field of cosmetic products and its preparation, and foundation products, which can solve the problems of incompatibility and achieve the effect of improving the lasting power, good powder adhesion and refreshing feeling of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

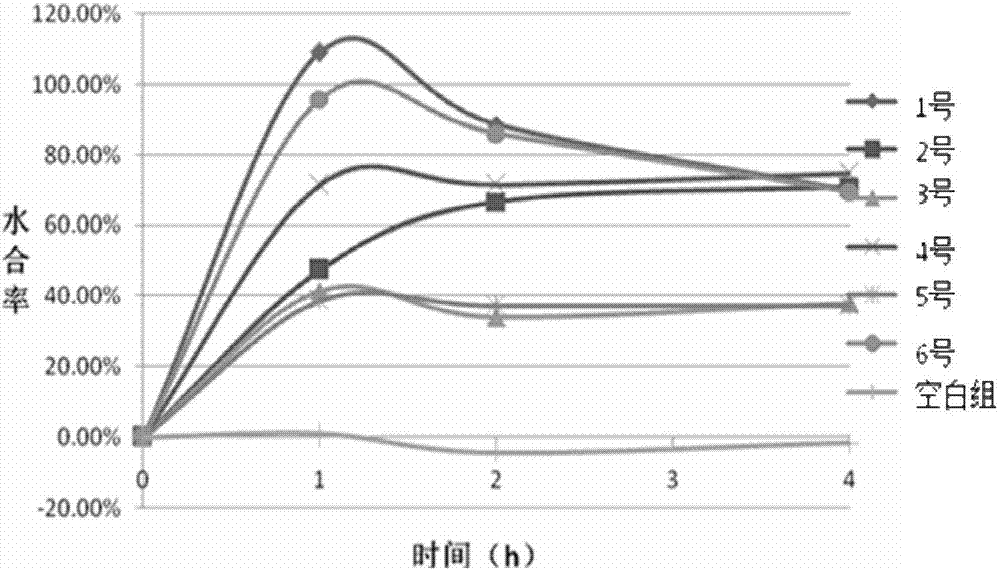

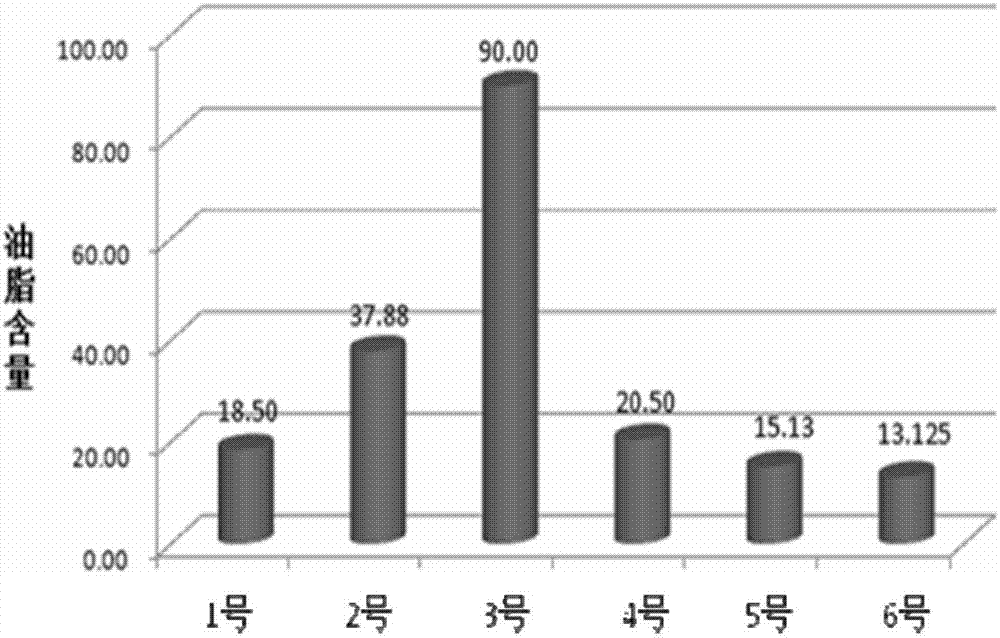

experiment example 1

[0068] Experimental Example 1 Performance Evaluation Experiment

[0069] 1. Stability evaluation

[0070] (1) Instruments and equipment

[0071] DGG-9140A electric constant temperature blast drying oven, BCD-196H Rongshida refrigerator.

[0072] (2) Evaluation items

[0073] A: Heat resistance:

[0074] Adjust the DGG-9140A electric heating constant temperature blast drying oven to 45°C, put the sample to be tested, take it out after 24 hours, and after returning to room temperature, there is no phenomenon of discoloration, water separation, and stratification. Each product of embodiment 1-3 was observed by the above-mentioned method for one month, and no abnormality was found.

[0075] B: cold resistance:

[0076] Put the sample to be tested into the freezer of a Royalstar refrigerator (temperature -10 to -15°C), take it out after 24 hours, and after returning to room temperature, there is no phenomenon of discoloration, water separation, or stratification. The samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com