Magnetic-vibration swing-impact-type ball milling device

An impact type and ball milling technology, which is applied in grain processing, etc., can solve problems such as mechanical wear and complex structure of mechanical transmission parts, and achieve the effects of easy cleaning, reduction of dead zones in the cabin, and convenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

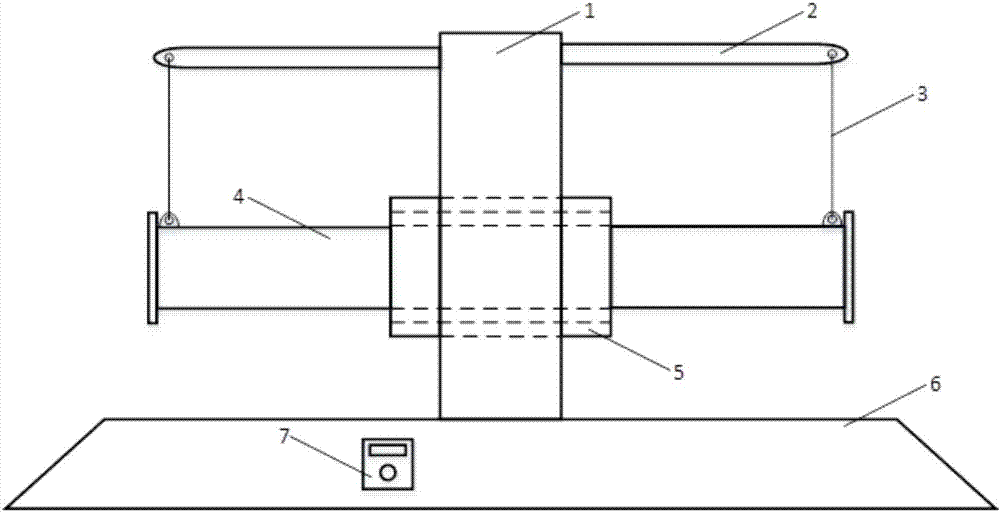

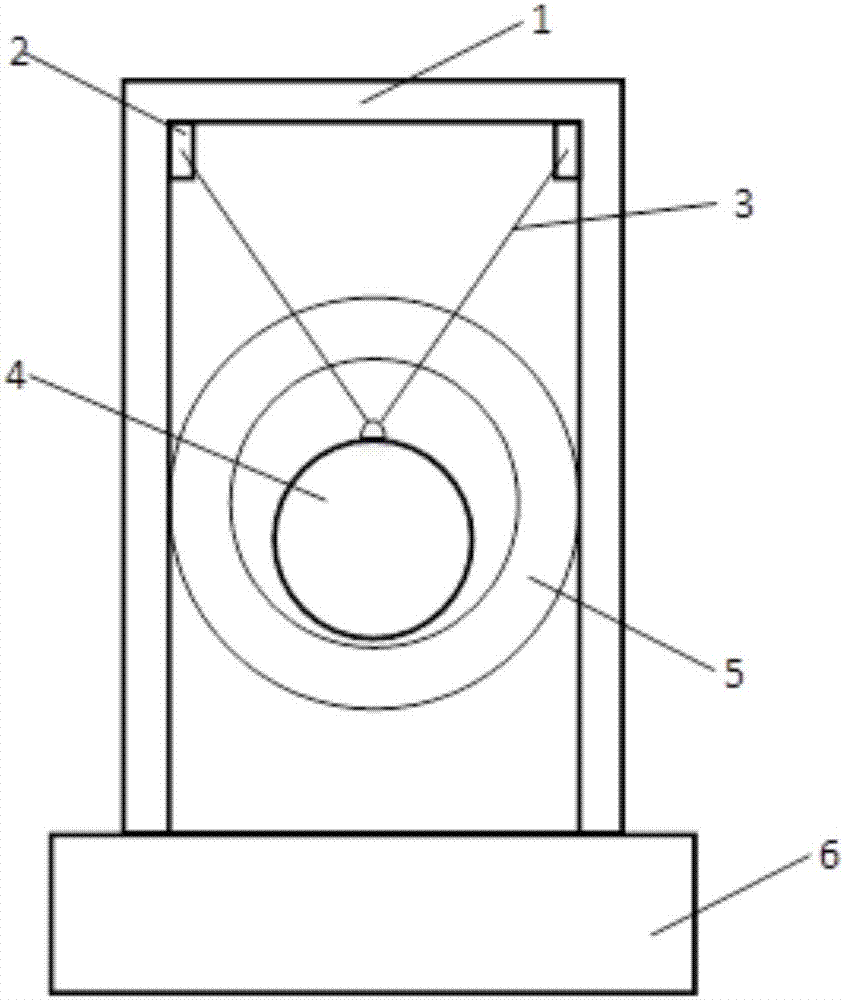

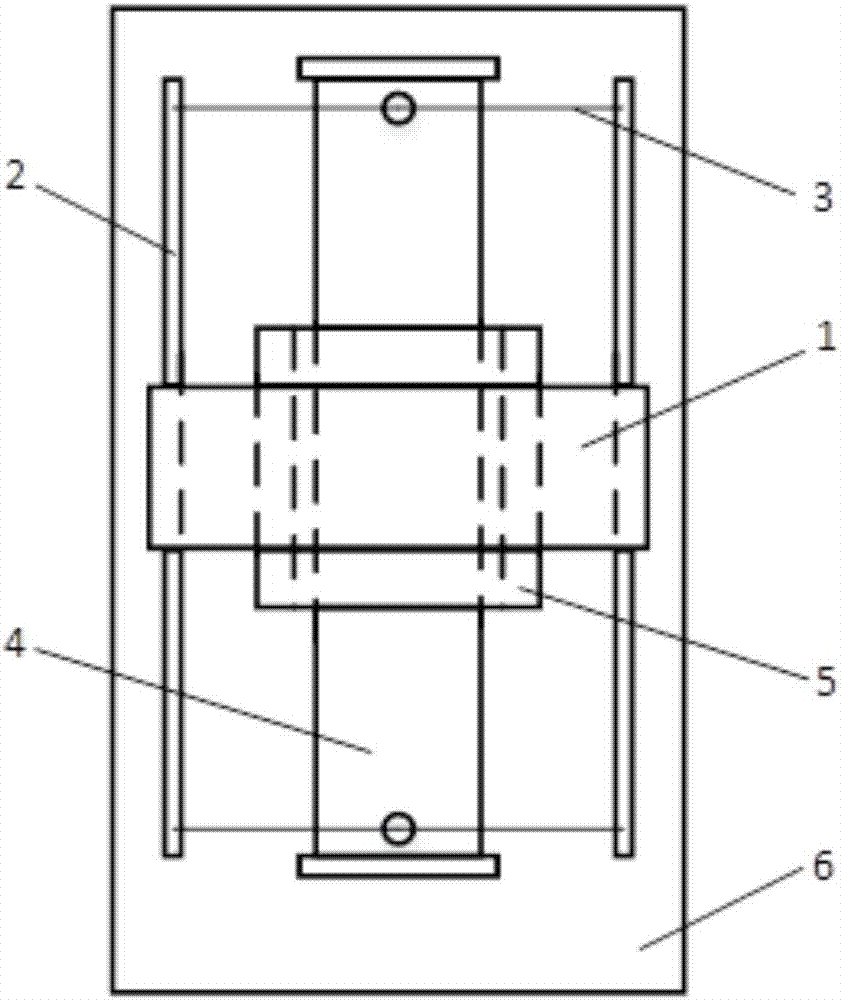

[0033] Such as Figure 1-3 As shown, a magnetic vibration swing impact ball milling device, the device includes a base 6, a door-shaped support 1 vertically arranged on the base 6, a double cantilever 2 fixed on the top of the door-shaped support 1 along the horizontal direction, and a The electromagnetic coil 5 on the door-shaped bracket 1, the AC frequency converter 7 electrically connected to the electromagnetic coil 5, and the cylindrical vibrator inserted in the electromagnetic coil 5 and connected to the double cantilever 2 through the cable 3 are arranged below. Unit 4, the cylindrical vibrator unit 4 forms a floating reciprocating motion system together with the cable 3, the electromagnetic coil 5 and the double cantilever 2. The cable 3 is a V-shaped flexible cable. In the working state, the AC frequency converter 7 controls the electromagnetic The coil 5 generates an alternating magnetic field, and the cylindrical vibrator unit 4 reciprocates under the action of the ...

Embodiment 2

[0038] In this embodiment, there are three grinding cabins 11, and the drag cables 3 are V-shaped rigid drag cables. All the other are with embodiment 1.

Embodiment 3

[0040] In this embodiment, there are four grinding chambers 11 in total. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com