Strong turning tool with adjustable chip breaking block and use method thereof

A chip-breaking and powerful technology, which is applied in the direction of lathe tools, turning equipment, tool holder accessories, etc., can solve the problem of limited position adjustment function of turning tool chip breaking block, insufficient position stability of turning tool chip breaking block, cutting tool The rod cannot be used multiple times, etc., to achieve the effect of improving the service life, saving man-hours, and cutting the material of the cutter rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

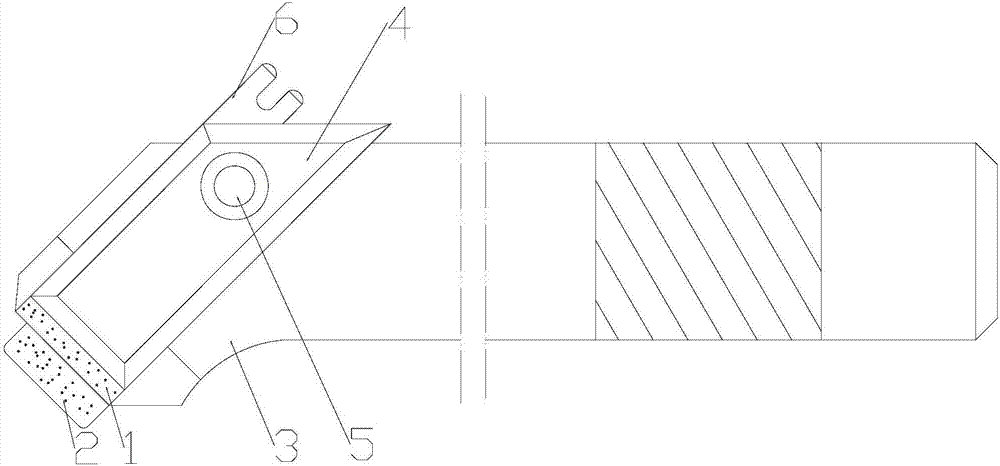

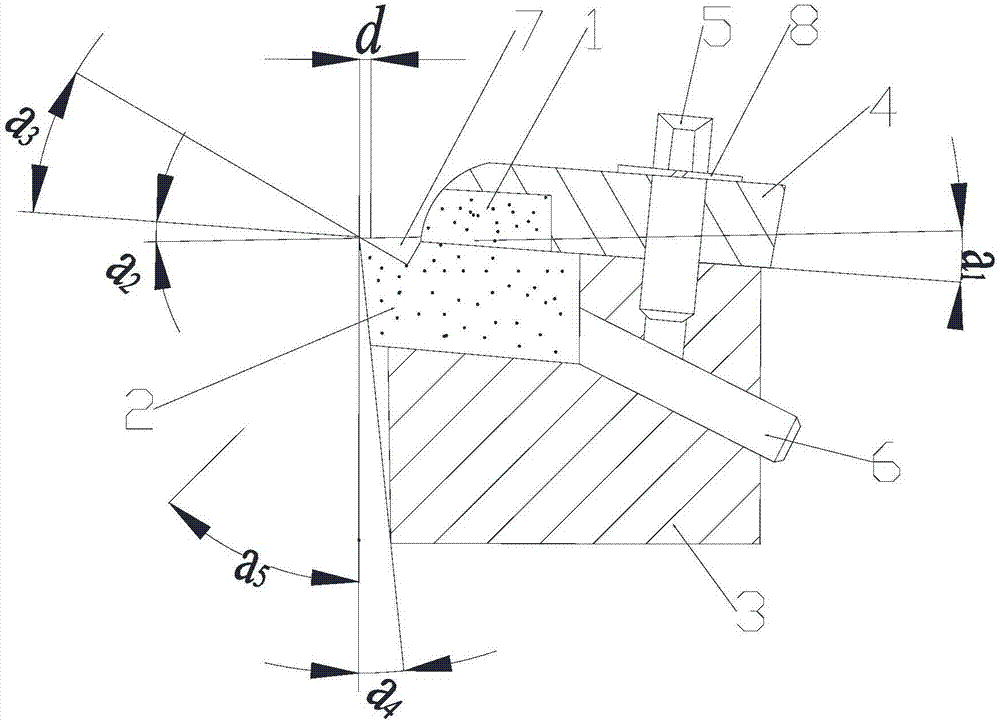

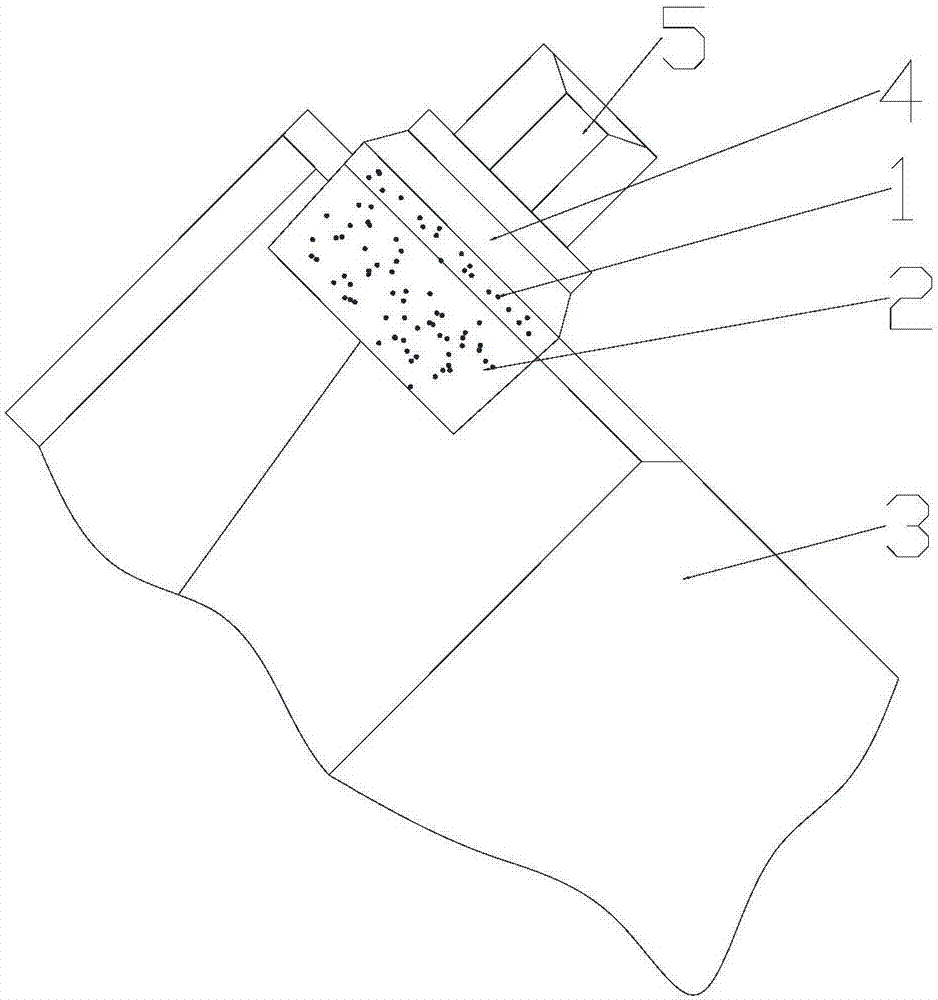

[0032] Such as Figure 1-Figure 3 As shown, a powerful turning tool with an adjustable chip breaking block includes a chip breaking block 1, a blade 2, a tool bar 3, a pressing piece 4, a clamping screw 5 and an adjusting screw 6, and the upper end surface of the tool bar 3 end is set There are parallelogram blade installation slots and adjustment screw holes, the upper surface of the end of the knife bar 3 is inclined downward from front to rear, and is parallel to the lower side of the blade installation slot, the front side and upper side of the blade installation slot Both openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com