An aluminum profile cutting machine

A cutting machine and aluminum profile technology, which is applied in metal processing machinery parts, manufacturing tools, positioning devices, etc., can solve the problems of low cutting operation efficiency, the aluminum material is not flat enough, and the cutting process is cumbersome, so as to avoid the sputtering of aluminum chips, Improve the adjustment accuracy and improve the effect of the limit fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

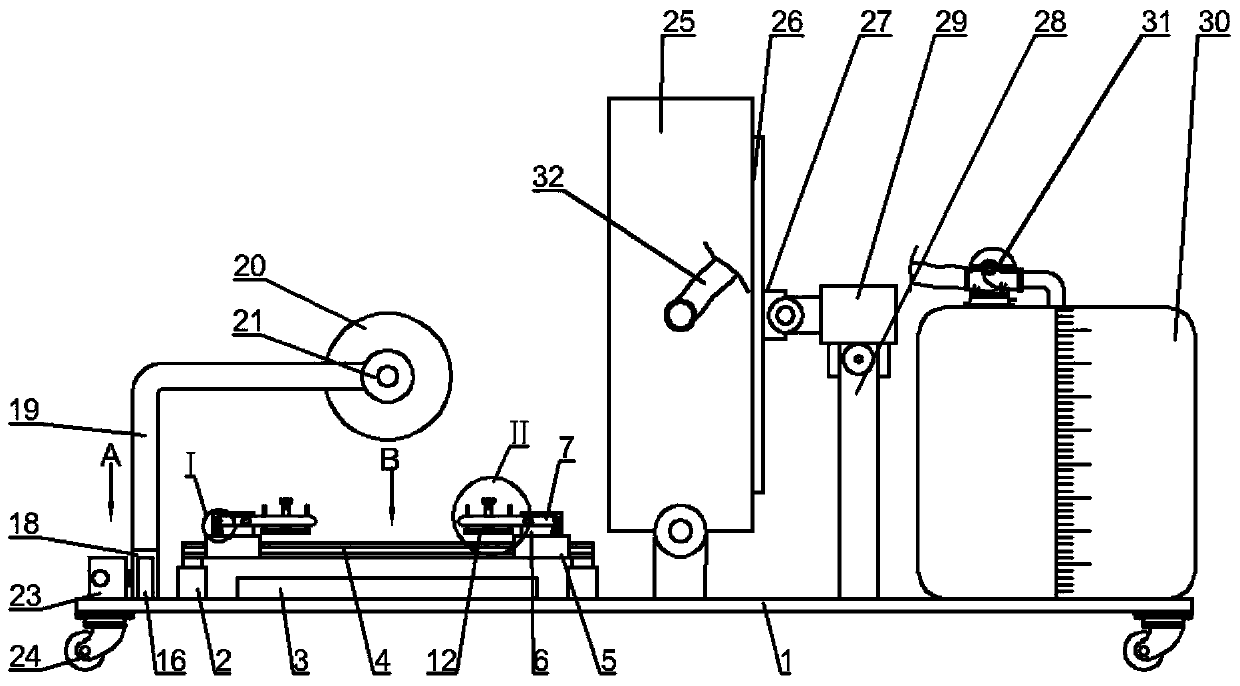

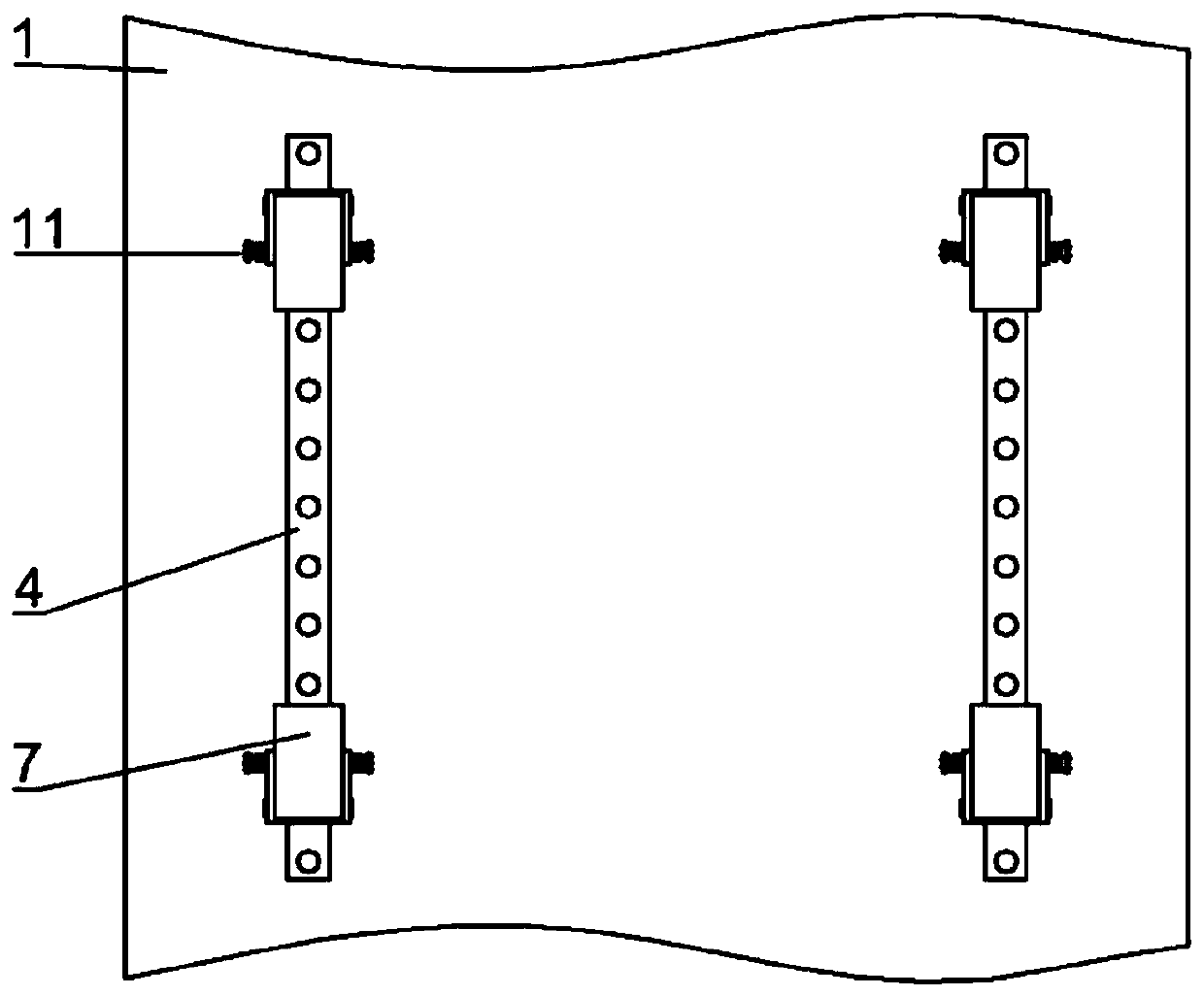

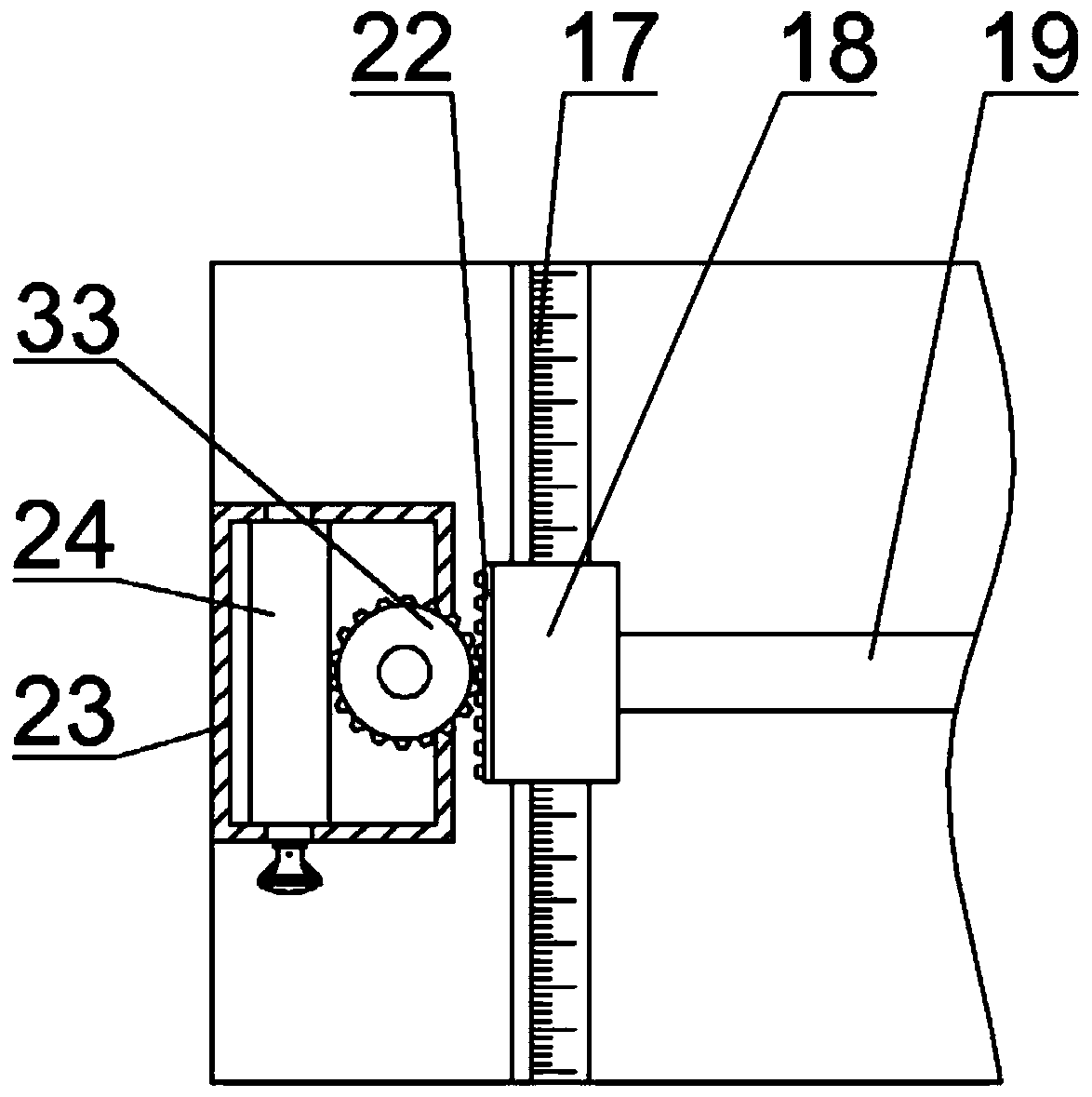

[0023] see Figure 1-6 , an aluminum profile cutting machine, including a base plate 1, a water tank 30, a micro-adjustment device, a first slide rail 4, a second slide rail 16, a first electro-hydraulic rod 2, a pressing device and a cutting wheel 20, the base plate 1 Two groups of first electro-hydraulic rods 2 arranged left and right are fixedly installed on the left side of the upper part, and the free ends of each group of first electro-hydraulic rods 2 are fixedly connected with first slide rails 4, and the upper part of each first slide rail 4 is movable. Two sliding sleeves 5 are socketed, and a pair of fixed plates 6 are fixedly connected to the upper part of the sliding sleeves 5, and the middle of the fixed plates 6 is hinged with a trigger plate 7, and the hinge of the trigger plate 7 is integrally formed with an arc-shaped protrusion 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com