Cutting machining device for edges of guitar

A cutting and guitar technology, applied in the field of guitar edge cutting and processing devices, can solve problems such as lifting, and achieve the effect of high cutting efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

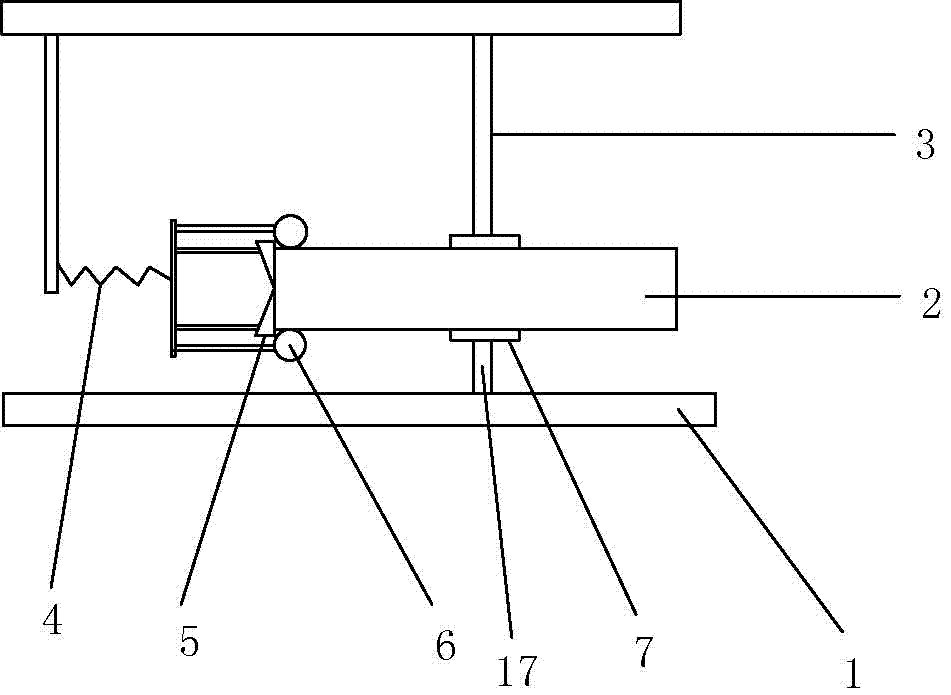

[0026] Such as figure 1 As shown, the guitar edge cutting processing device of the present invention comprises a frame 1, and the frame 1 is rotatably connected with an upper pressing bar 3 and a lower pressing bar 17 for fixing the guitar 2, and the upper pressing bar 3 and the lower pressing bar 17 are connected with the guitar 2 respectively. The upper and lower plates offset each other. The upper pressing rod 3 is a telescopic rod, in which the first spring (not shown) is affixed. In order to fix the guitar 2 better, a rubber suction cup 7 can be installed at the contact of the upper pressing rod 3 and the guitar 2, and the contact of the lower pressing rod 17 and the guitar 2. The frame 1 on the left side of the upper bar 3 is slidably provided with a clamping ball 6 for clamping the upper and lower plates of the guitar 2 and a blade 5 for cutting the edges of the upper and lower plates of the guitar 2. The blade 5 is fixed on the base, and the clamping The ball 6 is ro...

Embodiment 2

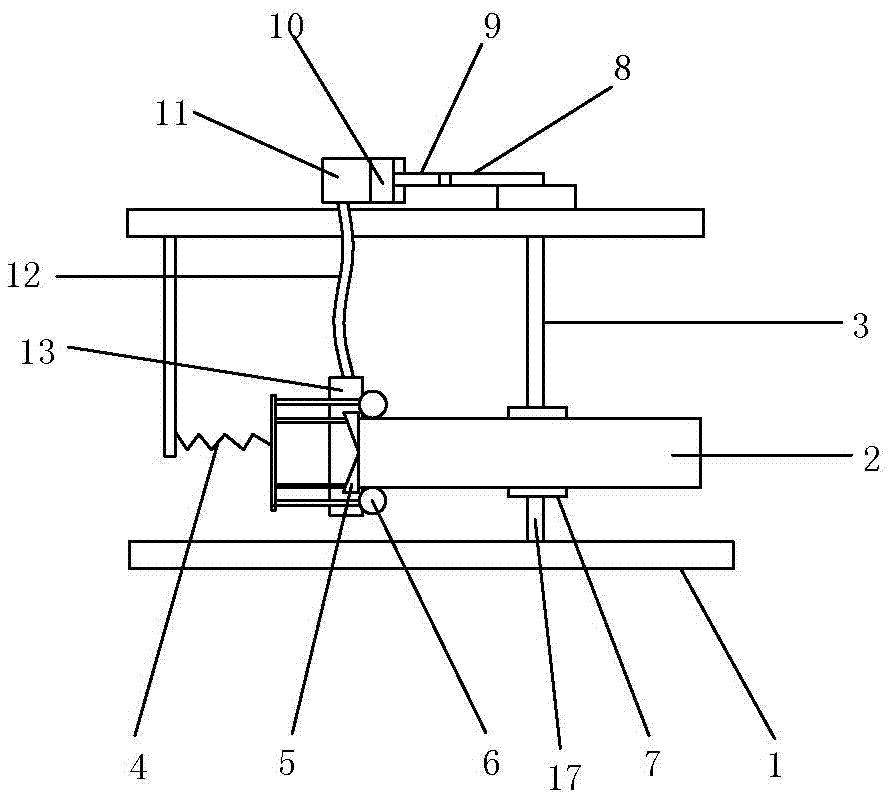

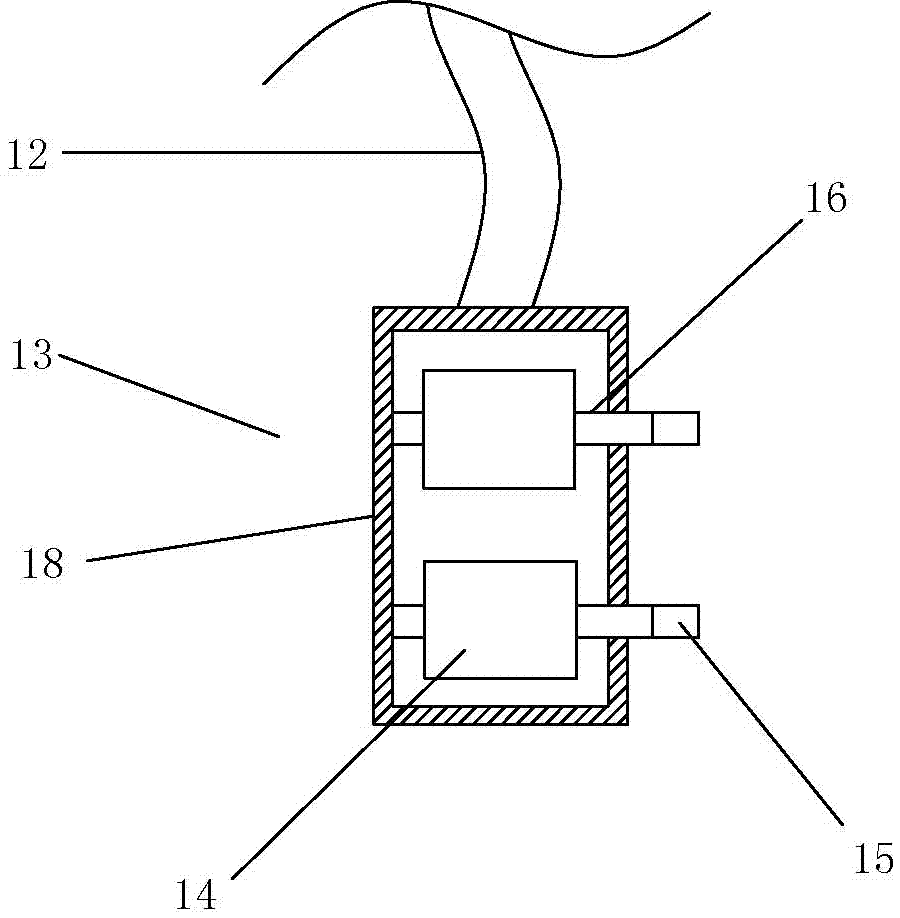

[0029] Such as figure 2 and image 3 As shown, the difference between the present embodiment and the first embodiment is that a crank 8 coaxially connected with the upper pressing rod 3 is rotatably connected to the frame 1 , and the left end of the crank 8 is respectively connected with the connecting rod 9 and the slider 10 . The outer sealing sleeve of the slide block 10 is provided with a cylinder 11. In order to increase the sealing performance of the cylinder 11, a rubber sleeve can be provided outside the slide block 10. The cylinder 11 is affixed with a vertically downward flexible pipe 12, and the free end of the flexible pipe 12 is affixed with a polishing device 13. Such as image 3 As shown, the grinding device 13 includes a hard tube 18 connected to the hose 12, two rotating shafts 16 are rotatably connected to the inner wall of the hard tube 18, blades 14 are connected to the rotating shaft 16, and the right end of the rotating shaft 16 is sleeved with a Grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com